50TPH Rock Gold Mineral Processing Plant In Malaysia

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project Info.

- Raw ore: rock gold mineral

- Capacity: 50TPH

- Maximum feed size: 250 mm

- Output: gold bar

- Location: Malaysia

Process

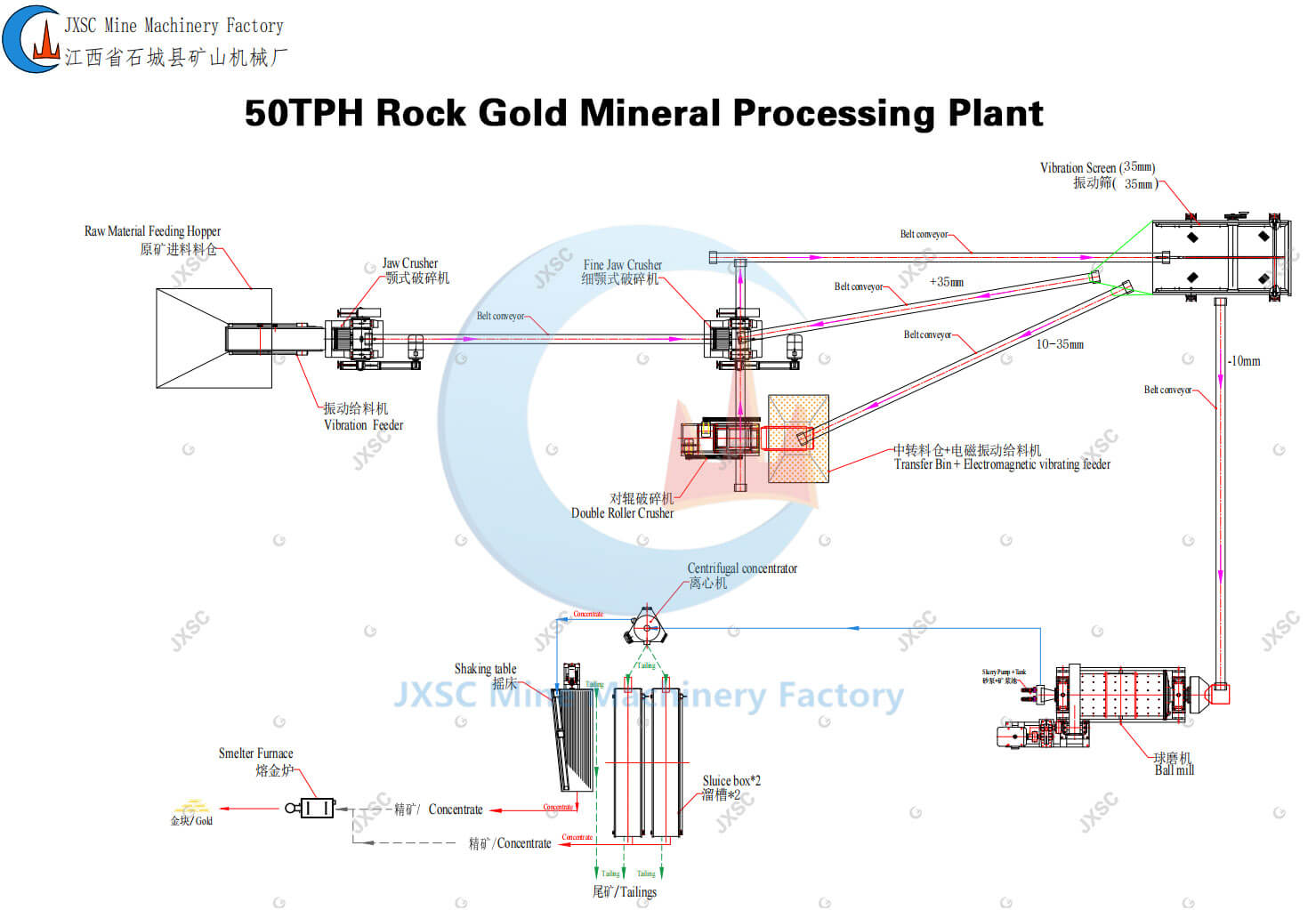

Three-stage crushing – screening – grinding – gravity separation (centrifugal concentrator, shaking table, sluice box)

process flow

50TPH Rock Gold Mineral Processing Plant

This is a complete 50TPH (tons per hour) rock gold mineral processing project in Malaysia, for which JXSC provided a full solution. The 50TPH rock gold process is designed around “efficient crushing – precise classification – multi-stage separation,” achieving full processing from raw ore to gold nuggets. The specific steps are as follows:

50TPH Rock Gold Mineral Processing Flow

1. Ore feeding and primary crushing

Main Equipment: Feeding Hopper, Vibration Feeder, Jaw Crusher

Raw gold ore to be processed is stored and evenly transported to the crushing system via a vibration feeder, ensuring stable operation of subsequent equipment. A coarse jaw crusher performs initial crushing of the ore, reducing large lumps to medium-sized particles in preparation for secondary crushing.

2. Fine Crushing and Screening Stage

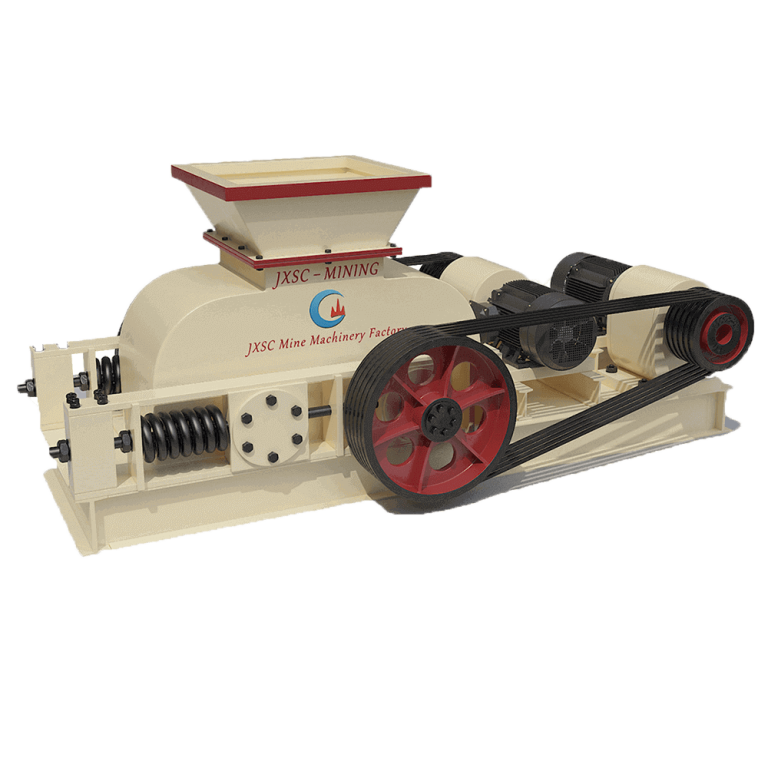

Main Equipment: Fine Jaw Crusher, Double Roller Crusher, Vibrating Screen

The fine jaw crusher further crushes the coarsely crushed ore, reducing its particle size to a finer level. The vibrating screen, with a mesh size of 35mm, classifies the crushed ore. Coarse particles larger than 35mm are returned to the fine jaw crusher for secondary crushing. Medium particles between 10-35mm enter the double roller crusher for secondary crushing. Fine particles less than 10mm are conveyed by a belt conveyor to the ball mill. The double roller crusher crushes the medium particles between 10-35mm, ensuring that the ore particle size meets subsequent grinding requirements and improving grinding efficiency.

3. Grinding and Concentration Stage

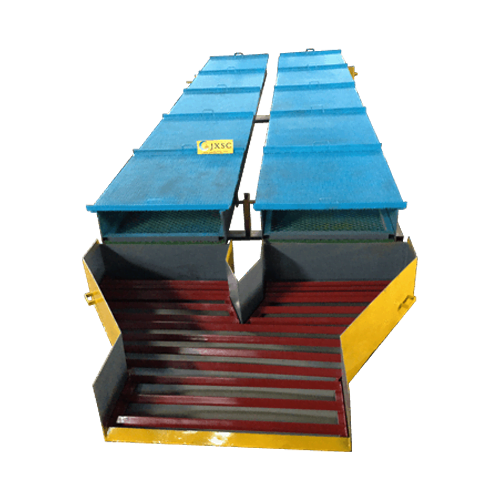

Main Equipment: Ball Mill, Slurry Pump, Centrifugal Concentrator, Shaking Table, Gold Chute

The ball mill grinds fine ore into an even finer slurry, fully dissociating the gold minerals. The slurry is pumped to the concentrator via a slurry pump. The centrifugal concentrator utilizes centrifugal force to efficiently recover coarse gold particles from the slurry, serving as a preliminary enrichment method.

The shaking table and two sluice boxes perform deep concentrating on the slurry after the centrifugal concentrator, separating the gold minerals from the gangue by gravity, producing a high-grade concentrate. Tailings are then discharged from the system.

4. Concentrate Smelting Stage

Main Equipment: Gold Melting Furnace

The sorted gold concentrate enters the smelting furnace, ultimately producing high-purity finished gold nuggets, completing the entire mineral processing flow.

Mining resource endowments (such as ore properties, gold grade, and particle size composition) vary significantly, making standardized processes difficult to adapt to all scenarios. With over 40 years of experience in the mining machinery industry, JXSC adheres to the principle of “adapting to local conditions and tailoring our services,” providing comprehensive, customized solutions from process design and equipment selection to installation, commissioning, and technical training. Whether you’re dealing with sulfide ores, placer/alluvial gold, rock gold ores, low-grade gold deposits, or complex polymetallic ores, contact us to get professional gold mineral processing technology and full gold mining equipment!

Process Site

50TPH Rock Gold Mineral Processing Plant Solution

Advantages Of The 50TPH Rock Gold Mineral Process

√ Efficient Crushing and Classification: Utilizing a multi-stage crushing and screening process consisting of jaw crusher + fine jaw crusher + roller crusher + vibrating screen, the system ensures uniform ore particle size. This meets grinding requirements, reduces subsequent energy consumption, and is suitable for various throughput designs, ranging from 20 TPH to 100 TPH.

√ Deep Separation and High Recovery: Combining various gravity separation equipment, such as centrifugal concentrators and shaking tables, the system performs multi-stage separation tailored to the characteristics of the rock gold ore, significantly improving gold recovery and reducing resource waste.

√ Stable and Automated Process: Auxiliary equipment, such as transfer silos and electromagnetic vibrating feeders, ensures continuous and stable material transportation, reducing manual intervention and improving production continuity and stability.

√ High Adaptability: Customized design tailored to the ore properties of Malaysian rock gold mines (such as hardness and gold intercalation), ensures that equipment selection matches process parameters, guaranteeing a 90%+ beneficiation efficiency.

√ Environmental Protection and Resource Maximization: The gravity separation process eliminates the need for chemical agents, reducing environmental pollution and aligning with green mineral processing principles.

Main Equipment

| No. | Product Name | Model No. | Detail Descriptions | Power (KW) | Qty (Set) |

| 1 | Vibrating Feeder | DN380*96 |

| 11 | 1 |

| 2 | Jaw Crusher | PE-500*750 |

| 55 | 1 |

| 3 | Belt conveyor#1 | B650*15m |

| 7.5 | 1 |

| 4 | Fine jaw crusher | PEX-300*1300 |

| 55 | 1 |

| 5 | Belt conveyor #2 | B800*10m |

| 4 | 1 |

| 6 | Belt conveyor #3 | B800*15m |

| 7.5 | 1 |

| 7 | Vibrating Screen | 2YD1548 |

| 15 | 1 |

| 8 | Belt conveyor #4 | B650*17m |

| 11 | 1 |

| 9 | Belt conveyor #5 | B650*17m |

| 11 | 1 |

| 10 | Feeder for double roller crusher | 1600*800 *300 |

| 0.2 | 1 |

| 11 | Double roller crusher | 2PGY- 1000*800 |

| 90 | 1 |

| 12 | Belt conveyor #6 | B650*18m |

| 11 | 1 |

| 1 | Grate discharge ball Mill | MQZ2740 |

| 400 | 1 |

| 2 | Steel Ball | / |

| 0 | 40 |

| 1 | Slurry pump | 6/4 |

| 30 | 1 |

| 2 | Gold Centrifugal Concentrator | STLB100 |

| 18.5 | 1 |

| 3 | New type big Shaking Table | 4500*1850mm |

| 1.1 | 1 |

| 4 | Sluice Box | 6m*1m |

| 0 | 2 |

| 5 | Gold smelting furnace | 25A |

| 5 | 1 |

| 6 | #1 Main Water Pump | 150-125-250 |

| 18.5 | 1 |

| 7 | #2 Back wash Water Pump | 100-80-125 |

| 11 | 1 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.