Belt Feeder

Capacity: 10-450TPH

Feeding size: 1-100mm

Application: Belt feeder commonly used in mining, mineral processing, construction, sandstone plant, brick factory, coal, chemical and other industries, such as feeding and conveying of raw materials such as ore, sandstone aggregate, coal, etc.

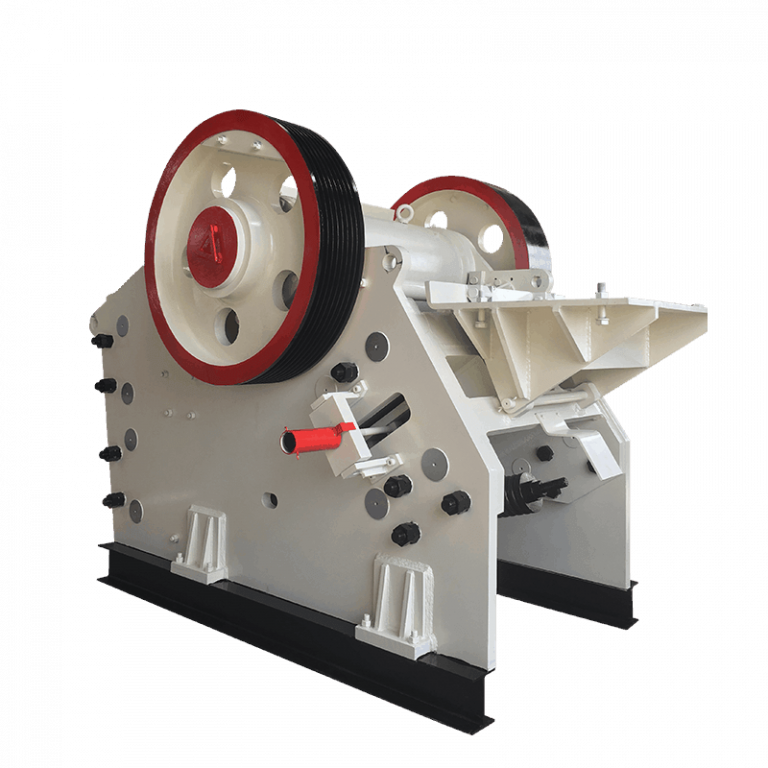

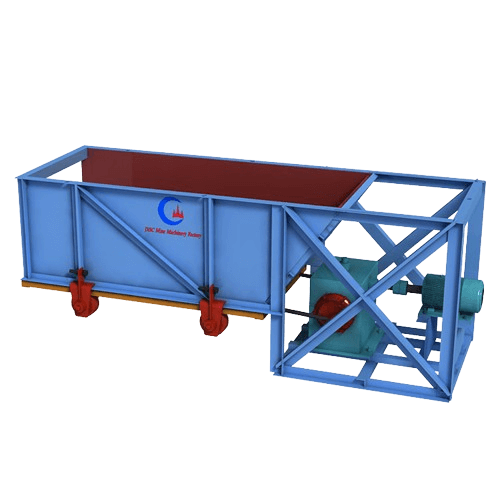

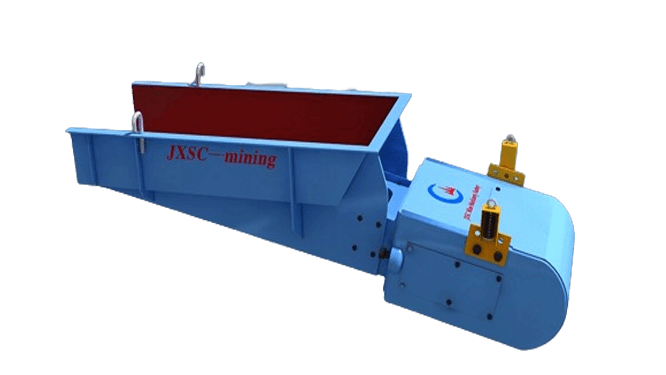

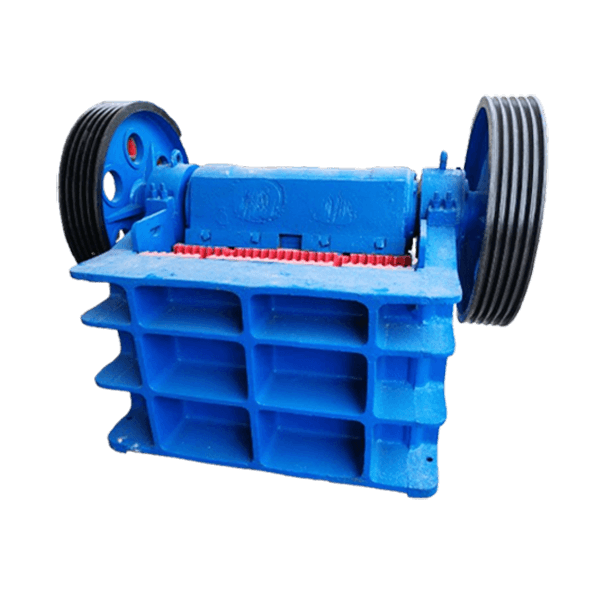

Products display

Introduction of Belt feeder

The belt feeder is an integrated machine composed of a hopper and a belt conveyor. The frequency converter is used to adjust the feeding and belt conveying speed to achieve uniform feeding. It is mainly used to efficiently, evenly and stably transport bulk, block and granular materials from one location to another or to the receiving equipment. In mining and mineral processing, the belt feeder is a very popular feeding equipment.

Its core advantages lie in its long conveying distance, adaptability to various material forms, and ability to be installed on the ground, inclined, or horizontally. This belt feeder can not only realize the continuous feeding of ordinary materials, but also meet the special conveying needs of high-temperature, dusty, and corrosive materials. It is a “flexible conveying link” connecting silos, crushers and screening equipment in the production line. It is especially suitable for long-distance and large-flow material transfer feeding stages. JXSC can be designed with wheels form mobile type feeding equipment to ensure that the machine is light and flexible when moving.

Principle and structure of belt feeder

Working principle

The belt feeder is mainly composed of a hopper, a belt conveyor, a transmission device, a motor, a belt, rollers and a frame. The material is fed to the belt surface of the belt feeder through the feeding hopper. As the AC speed regulating motor rotates, the belt runs along the path of the rollers driven by the drive motor. The belt moves forward slowly, and the material on the belt surface is fed to the next process through the first round to achieve continuous feeding.

Structural characteristics

- Drive unit: Motor + reducer.

- Conveyor belt: Wear-resistant rubber/steel belt, carries the material.

- Puller assembly: Drive roller, bend roller, and tensioning roller.

- Idler support: Upper and lower idler rollers support the belt.

- Cleanser: Prevents material from sticking.

- Protective cover: Dust and rain protection (optional).

Why Choose JXSC Belt feeder

Features & advantages Of Belt feeder

√ Ultra-long distance conveying: The conveying distance of a single machine can be customized, and multiple machines can be connected in series to achieve kilometer-scale conveying, meeting the needs of various small to large production lines.

√ Large processing capacity: A variable-speed motor adjusts the feed rate by varying the belt speed, achieving high conveying capacity.

√ Adaptable: Belt materials are available (wear-resistant rubber, high-temperature stainless steel, or food-grade PU), and can be equipped with a sealed cover for dust-free conveying.

√ Stable operation and low maintenance: The rollers utilize sealed bearings for a low failure rate.

√ Flexible customization: The mobile belt feeder can be equipped with wheels to adapt to various industrial production environments.

models & specifications

Model | Width | Center distance of head and tail wheel or drum wheel (mm) | Head and tail wheel diameter | Feeding Capacity | Feeding Size(mm) | Motor Power | Weight |

500×1000 | 500 | 1000 | 219 | 10~100 | 0~50 | 0.75 | 266 |

500×1300 | 1300 | 10~100 | 0~50 | 2.2 | 503 | ||

500×1500 | 1500 | 10~100 | 0~50 | 2.2 | 552.7 | ||

500×2000 | 2000 | 10~100 | 0~50 | 2.2 | 609.4 | ||

500×2800 | 2800 | 10~100 | 0~50 | 2.2 | 670 | ||

500×3000 | 3000 | 10~100 | 0~50 | 2.2 | 697 | ||

500×4000 | 4000 | 10~100 | 0~50 | 2.2 | 736 | ||

650×1500 | 650 | 1500 | 10~100 | 0~50 | 2.2 | 610 | |

650×2600 | 650 | 2600 | 10~100 | 0~50 | 2.2 | 636 | |

650×4000 | 650 | 4000 | 10~100 | 0~50 | 2.2 | 893 | |

800×2000 | 800 | 2000 | 15~150 | 0~80 | 2.2 | 721 | |

800×3000 | 800 | 3000 | 15~150 | 0~80 | 7.5 | 857.3 | |

800×4000 | 800 | 4000 | 15~150 | 0~80 | 7.5 | 1012 | |

800×4500 | 800 | 4500 | 400 | 15~150 | 0~80 | 2.2 | 1200 |

1000×2000 | 1000 | 2000 | 200~450 | 0~80 | 3 | 1549 | |

1000×2500 | 2500 | 200~450 | 0~100 | 3 | 2105 | ||

1000×6000 | 6000 | 200~450 | 0~100 | 11 | 5214 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.