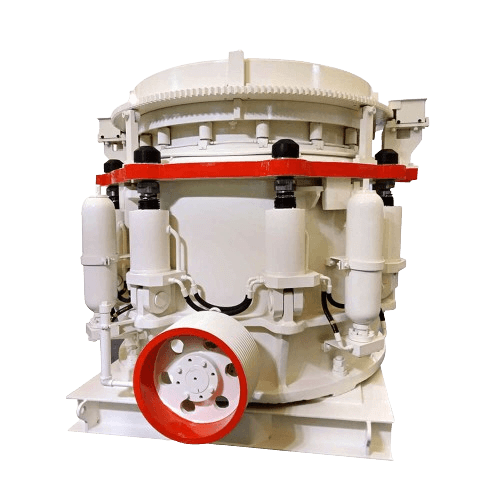

Cone Crusher

Types: Single-cylinder hydraulic cone crusher, Multi-cylinder hydraulic cone crusher, Symons cone crusher

Capacity: 27-1450 t/h

Feeding size: <425mm

Application: Cone crusher is used for crushing hard and medium-hard ores and rocks, such as gold, diamond, copper, manganese, iron ore, copper ore, limestone, quartz, granite, marble, and other mining, mineral processing, or construction aggregate production lines.

introduction of cone crushers

Cone crushers reduce the particle size of rock material to release valuable minerals from ores. Usually used as a secondary or tertiary crusher in the crushing circuit, the finished product has uniform and fine particle size. It can complete various medium, fine, and ultra-fine crushing operations from stone production to various ore crushing. Cone crusher is a key equipment for secondary/fine crushing in mining, mineral processing, and construction aggregate production plants due to its laminated crushing, intelligent control, and efficient fine crushing capabilities.

Our cone crushers are equipped with powerful motors. When its mantle rotates at high speed, it creates a large centrifugal force, turning the raw material into fine particles quickly. The crushing chamber has various types (standard/short head/intermediate type) to meet different particle size requirements, with low vibration during operation and long service life. Each size of JXSC cone crusher has three cavity types to choose from. We also support custom-made fixed or mobile cone crushers; contact us for factory prices!

Cone Crushers For sale

Types of Cone Crushers

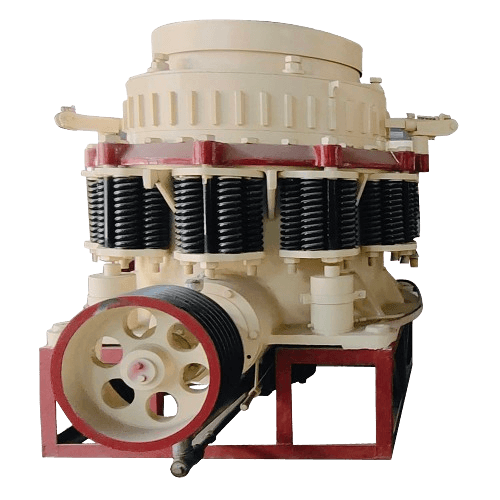

JXSC cone crusher models are diverse, customizable and fully meet the needs of various users. According to different crushing principles and product particle sizes, it is divided into many models: cylinder hydraulic cone crusher, spring cone crusher, compound cone crusher, Symons cone crusher, and mobile cone crusher.

- Feeding size: ≤220mm

- Capacity: 35-715 t/h

- Application: Single cylinder hydraulic cone crusher is suitable for crushing all kinds of hard and above medium hardness materials, such as river pebbles, limestone, dolomite, granite, rhyolite, and diabase.

- Advantages:

Less consumption of wearing parts and low running cost. The hydraulic discharge orifice is used to adjust the ore outlet in a timely and convenient manner, so that the crusher can work under the state of being full of feed. Only by replacing the lining board can different crushing cavity types be obtained, which can meet different process requirements of coarse and fine crushing. 【View More >>】

- Feeding size: ≤ 353mm

- Capacity: 90-1200t/h

- Application: Multi-cylinder hydraulic cone crusher is uaually used for crushing hard or medium hardness ore and rock, such as river pebbles, limestone, dolomite, granite, rhyolite, diabase, etc

- Advantages:

The hp hydraulic cone crusher adopts a fixed main shaft design, which combines the spindle speed, stroke and crushing cavity shape, thereby improving the production capacity and product quality and improving the fine crushing ability. In the crushing process, the layered crushing makes the aggregate shape has been greatly improved. 【View More >>】

- Feeding size: <425 mm

- Capacity: 27-1450 t/h

- Application: Symons/spring cone crusher is uaually used for crushing river pebbles, limestone, dolomite, granite, rhyolite, diabase.

- Advantages:

The spring cone crusher has a reasonable structure, excellent crushing principle and technical parameters, reliable operation, low operating cost, large crushing force, high production efficiency and high output. 【View More >>】

mobile cone crusher

Application field: Quarry, mining, coal mining, dry powder mortar, concrete mixing station, power plant desulfurization, quartz sand, etc.

Suitable material: crushing pebble, granite,basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc.

JXSC mobile cone crushers have wheel type and crawler type. Usually, it is also equipped with a vibrating feeder and a vibrating screen to form a one-stop crushing plant. It has great flexibility to adapt to any terrain to finish its crushing and screening operation.

models & specifications

Single cylinder Cone Crushers Parameter

| Model | Chamber | Feeding opening (mm) | Max feeding size (mm) | Minimum discharge(mm) | Maximum discharge (mm) | Motor power | Machine weight | Capacity | ||||

| Stroke | Stroke | Stroke | Stroke | Stroke | Stroke | KW | KG | t/h | ||||

| DNGP100 | A | 150 | 120 | 12 | 15 | / | 39 | 37 | 90 | 5800 | 35-135 | |

| B | 130 | 105 | 10 | 11 | / | 33 | 31 | |||||

| C | 100 | 85 | 7 | 9 | / | 33 | 30 | |||||

| DNGP200 | A | 220 | 180 | 18 | 22 | / | 35 | 30 | 160-220 | 12300 | 85-350 | |

| B | 150 | 120 | 15 | 19 | / | 35 | 30 | |||||

| C | 80 | 60 | 9 | 12 | / | 35 | 30 | |||||

| DNGP300 | A | 230 | 190 | 20 | 25 | / | 45 | 40 | 250-280 | 16500 | 115-400 | |

| B | 150 | 125 | 17 | 20 | / | 45 | 40 | |||||

| C | 80 | 60 | 10 | 13 | / | 40 | 35 | |||||

| DNGP500 | A | 230 | 180 | 22 | 26 | 30 | 50 | 45 | 40 | 315 | 25800 | 245-500 |

| B | 150 | 125 | 19 | 22 | 26 | 48 | 43 | 38 | ||||

| C | 100 | 80 | 12 | 14 | 16 | 40 | 35 | 30 | ||||

| DNGP600 | A | 280 | 220 | 22 | 26 | 30 | 45 | 35 | 30 | 355 | 26700 | 280-715 |

| B | 150 | 125 | 19 | 22 | 26 | 45 | 35 | 30 | ||||

Multi-cylinder cone crushers parameter

| Model | Feeding size (mm) | Discharging size (mm) | Power (KW) | Capacity (T/H) |

| HP200 | 50-185 | 5-19 | 130-200 | 90-250 |

| HP300 | 50-230 | 6-25 | 180-250 | 110-440 |

| HP400 | 50-295 | 6-30 | 280-355 | 140-630 |

| HP500 | 55-330 | 6-30 | 355-450 | 175-790 |

| HP800 | 90-353 | 6-32 | 550-630 | 260-1200 |

Symons cone crusher parameter

Model | Crushing Cone Dia(Feet) | Max feeding size(mm) | Discharge size range(mm) | Main machine power(KW) | Process capacity(T/H) |

DN900 | 3′(914) | 50-163 | 10-38 | 75 | 27-140 |

DN1200 | 4′ | 80-180 | 16-50 | 132 | 80-250 |

DN1300 | 4.25′(1295) | 70-238 | 10-51 | 155 | 50-360 |

DN1600 | 5.5′(1676) | 90-331 | 10-64 | 240 | 100-630 |

DN2100 | 7′(2134) | 120-425 | 13-64 | 315-400 | 300-1450 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.