Electromagnetic Vibrating Feeder

Applicable industries: Electromagnetic vibrating feeders are widely used in mining, metallurgy, coal, electronics, machinery, chemical industry, building materials, light industry, food and other industries.

Applicable materials: The electromagnetic vibrating feeder can transport ore, coal powder, cement, clinker, limestone, granular and block materials.

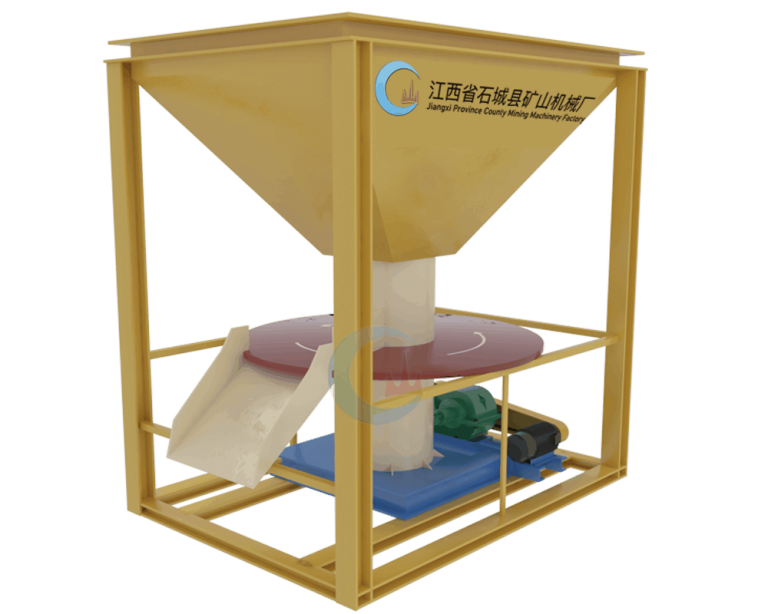

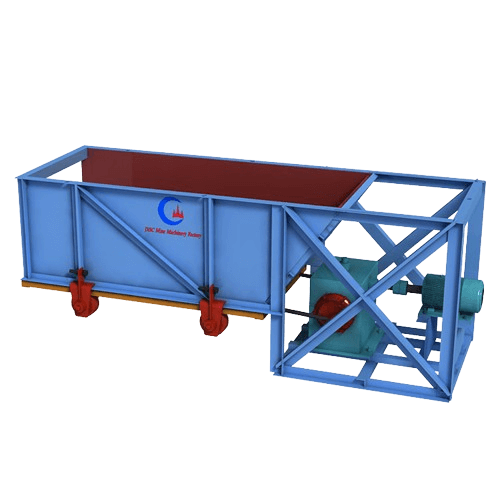

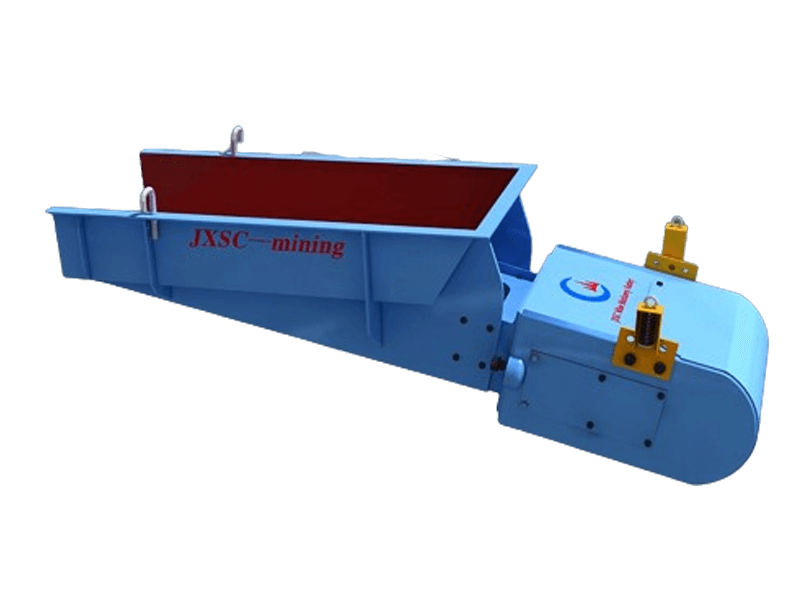

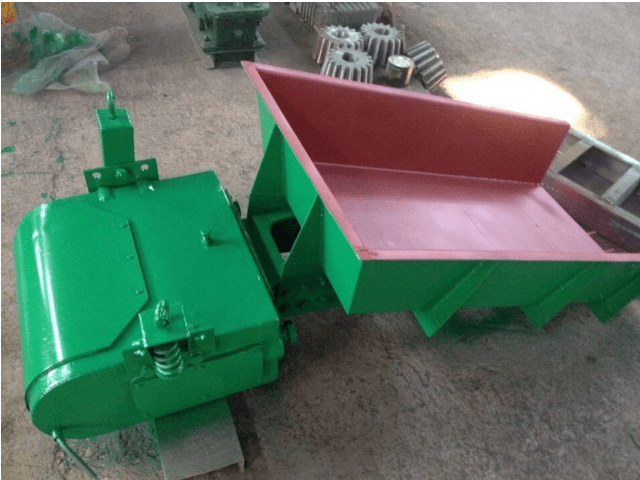

Products display

Introduction of Electromagnetic Vibrating Feeder

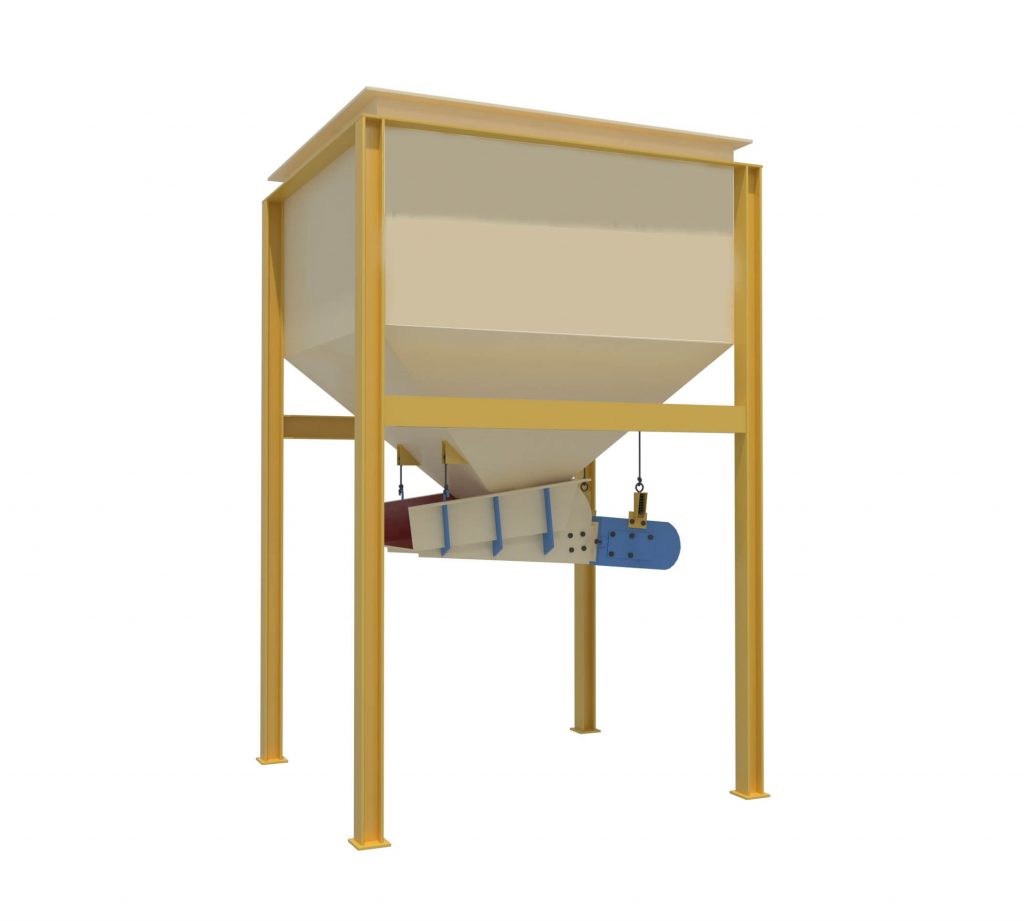

An electromagnetic vibrating feeder is an auxiliary equipment for transporting materials. In production, block, granular, and powdery materials are quantitatively, evenly, and continuously fed from the storage bin or funnel to the receiving device. An electromagnetic vibrating feeder uses high-frequency linear reciprocating vibration to feed materials. It is essential feeding equipment for the automation of flow operations. For example, it can feed materials to belt conveyors, bucket elevators, screening equipment, etc. It can feed materials to crushers, grinders, etc., and is also used for automatic batching, quantitative packaging, etc.

The core function of this feeder is to transport materials from the storage silo to downstream equipment evenly, quantitatively and continuously, realizing automated control of feeding, batching, quantitative packaging and other links, ensuring stable operation of the production line and improving material utilization. Due to its precise controllability, low maintenance costs, and strong environmental adaptability, it has become a core piece of equipment for automated production processes.

Principle and structure of electromagnetic vibrating feeder

Working Principle

The electromagnetic vibrating feeder uses the principle of mechanical dynamics, and the electromagnetic vibrator drives the feed trough to move periodically along the direction of the trough. When an electromagnetic coil is energized, a magnetic field is produced. This field attracts and repels the armature, causing the tray or slot to vibrate. The vibrations are transmitted to the bulk material, causing it to move forward along the pallet. The frequency and amplitude of vibration can be adjusted to control the flow of material. Finally, the material is evenly transported to the receiving device.

Structural Features

- Electromagnetic drive system: High-performance electromagnetic coils.

- No rotating parts: Utilizes half-wave rectifier circuit control, supporting stepless feed rate adjustment.

- Vibrating trough: Available in stainless steel, carbon steel, and wear-resistant lining.

- Control unit: Frequency converter adjusts amplitude and frequency.

- Elastic element: Rubber spring or coil spring; Shock-absorbing bracket and anti-loosening bolt structure significantly reduces base vibration.

Why Choose JXSC Electromagnetic Vibrating Feeder

Features & advantages Of Electromagnetic Vibrating Feeder

1. JXSC electromagnetic vibrating feeder is small in size, light in weight, simple in structure, and easy to install.

2. Low power consumption, no rotating parts requiring no lubrication, easy maintenance, and low operating costs.

3. The material flow can be changed and opened, and closed instantaneously, so the feeding amount is highly accurate.

4. The closed structure body can prevent dust pollution.

5. No lubrication required, simple structure, few wearing parts. The trough is made of wear-resistant alloy steel plate, which has a low wear rate.

6. The electromagnetic vibrating feeder can adjust the feeding amount and realize centralized control and automatic control of the production process.

models & specifications

Model | Discharge chute size length x width x height(mm) | Max Feeding Size(mm) | Feeding Capacity | 220 | Motor Power | Weight | Overall dimensions length x width x height(mm) |

GZ1 | 600×200×100 | 50 | 5-10 | 220 | 0.06 | 80 | 910×376×485 |

GZ2 | 800×300×120 | 50 | 10-20 | 220 | 0.15 | 165.5 | 1175×608×600 |

GZ3 | 900×400×150 | 75 | 20-30 | 220 | 0.2 | 223 | 1325×578×675 |

GZ4 | 1100×500×200 | 100 | 30-50 | 220 | 0.45 | 462 | 1616×762×814 |

GZ5 | 1200×700×250 | 150 | 50-100 | 220 | 0.65 | 656 | 1815×840×980 |

GZ6 | 1600×900×250 | 200 | 100-150 | 380 | 1.5 | 1252 | 2410×1092×1500 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.