Gravel Pump

Capacity: 36-4320 m3/H

Size: 4″ to 18″

Head: 5-80 mm

Speed: 300-2930 rpm

Handling solids: 0-260 mm

Concentration: 0-70%

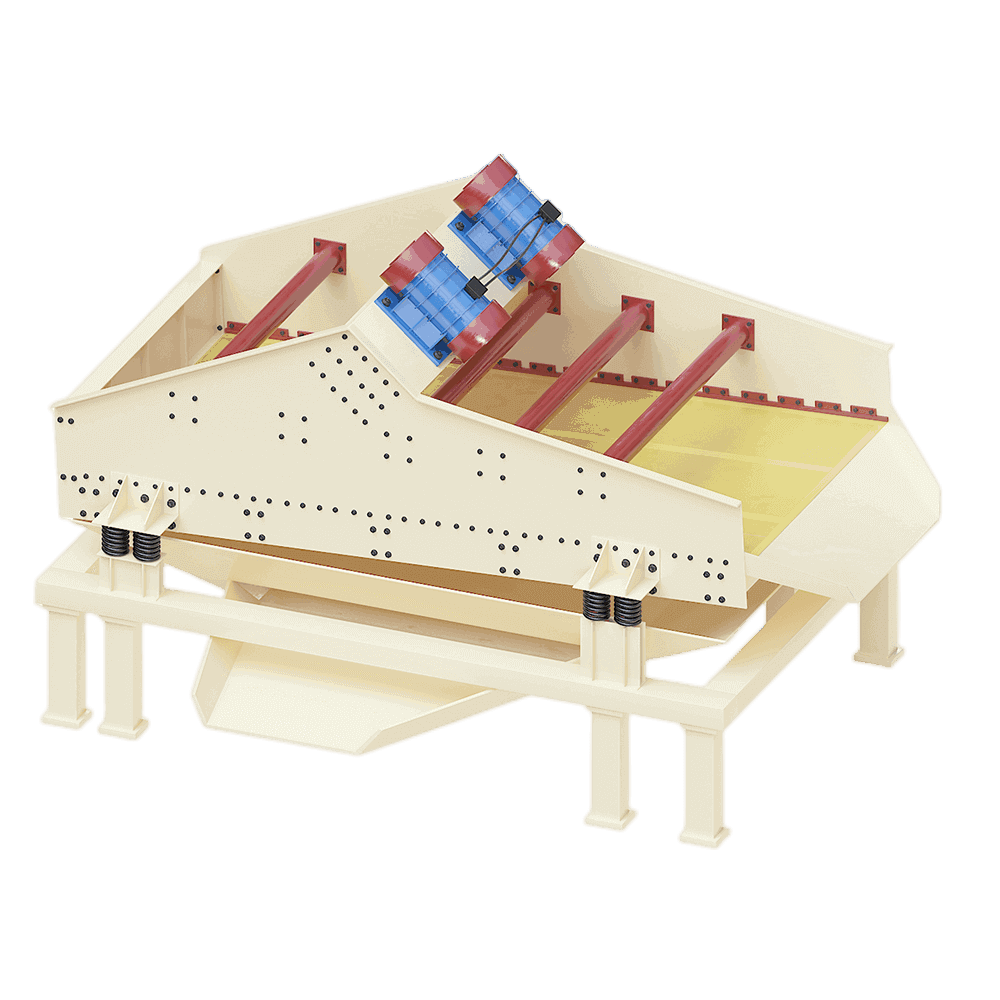

Products display

introduction of gravel pump

Gravel pumps are horizontal single-casing slurry pumps with wide passage to transfer sand or slurry with big particle size. The wet parts lare made of Ni-hard and high-Chrome alloys to ensure long service life.MPG gravel pumps has far better performance than common pumps in dredging, sand mining, barge loading and mineral processing, etc. Featured with all the advantages of MPG, MPGH series gravel pumps have achieved extra high head for special working conditions.

Application Of Gravel Pump

- 14/12G-G gravel pumps-generally used as dredger dredging pumps, river dredging pumps, sand pumping pumps for sand dredgers, mining and metal smelting explosion slag pumps, etc.

- The GH type is a high-lift gravel pump, which is mainly used for continuous transportation of large particles and strong abrasive materials that are too large to be transported by ordinary slurry pumps.

- G/GH sand gravel slurry pump transports strong abrasive and large particle slurry, such as mining, metal smelting explosion slag transportation, mud boat dredging, river dredging, etc.

why choose JXSC Gravel Pump

features of Gravel Pump

1. Special clamps are used to tighten the pump body and pump cover. The direction of the outlet of the pump can be in any position at 360 degrees, which is easy to install and use.

2. The bearing assembly adopts a cylindrical structure, which is convenient to adjust the gap between the impeller and the pump body. It can be removed as a whole during maintenance, and the bearings are lubricated with grease.

3. The shaft seal of the pump includes packing seal, impeller seal and mechanical seal.

4. The pump has a wide flow path, good cavitation performance, high efficiency and corrosion resistance.

5. The transmission modes mainly include V-belt transmission, elastic coupling transmission, gear reduction box transmission, hydraulic coupling transmission, variable frequency driving device, SCR speed control, etc.

6. The wetted parts are made of high-hardness wear-resistant Taijin cast iron.

7. Various speeds and various deformation methods are adopted to make the pump run under the best conditions. It has a long service life and high operating efficiency, and can meet many types of harsh transportation conditions.

8. Mainly used for continuous conveying of strongly abrasive materials that are too large to be conveyed by ordinary slurry pumps. It is suitable for dredging, sucking sand and gravel, dredging river channels, river sand mining and metal smelting explosion slag transportation.

models & specifications

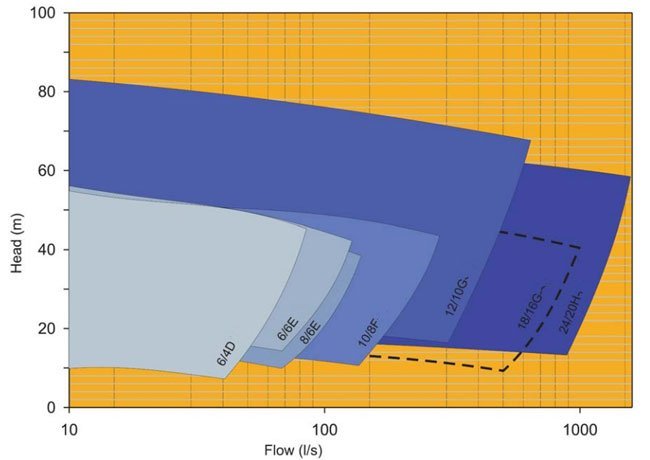

Model | Max. Power P (kw) | Capacity Q (m3/h) | Head H (m) | Speed n (r/min) | Eff. η (% ) | NPSH (m) | Impeller Dia. (mm) |

6/4D-G | 60 | 36-250 | 5-52 | 600-1400 | 58 | 2-5.5 | 378 |

6/4E-G | 120 | 36-250 | 5-52 | 600-1400 | 58 | 2-5.5 | 378 |

8/6E-G | 120 | 126-576 | 6-45 | 800-1400 | 60 | 3-4.5 | 391 |

10/8S-G | 560 | 216-936 | 8-52 | 500-1000 | 65 | 3-7.5 | 533 |

10/8S-GH | 560 | 180-1440 | 24-80 | 500-950 | 72 | 2.5-5 | 711 |

10/8F-G | 260 | 216-936 | 8-52 | 400-800 | 65 | 3-7.5 | 533 |

12/10F-G | 260 | 360-1440 | 10-60 | 350-700 | 65 | 1.5-4.5 | 667 |

12/10G-G | 600 | 360-1440 | 10-60 | 400-850 | 65 | 1.5-4.5 | 667 |

12/10G-GH | 600 | 288-2808 | 16-80 | 350-700 | 73 | 2-10 | 950 |

14/12G-G | 600 | 576-3024 | 8-70 | 300-700 | 68 | 2-8 | 864 |

14/12T-G | 1200 | 576-3024 | 8-70 | 300-700 | 68 | 2-8 | 864 |

16/14G-G | 600 | 720-3600 | 18-45 | 300-500 | 70 | 3-9 | 1016 |

16/14T-G | 1200 | 720-3600 | 18-45 | 300-500 | 70 | 3-9 | 1016 |

16/14TU-GH | 1200 | 324-3600 | 26-70 | 300-500 | 72 | 3-6 | 1270 |

18/16TU-G | 1200 | 720-4320 | 12-48 | 250-500 | 72 | 3-6 | 1067 |

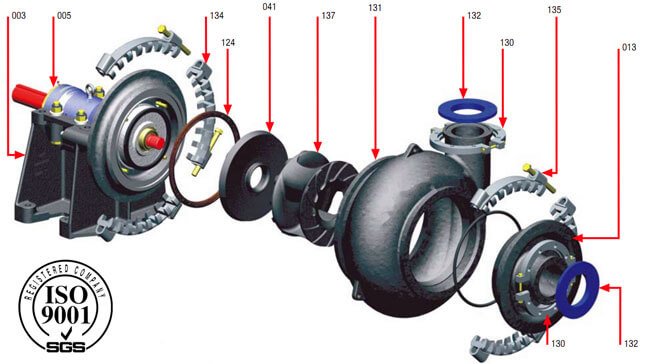

Construction of G Gravel pump

Main Part Number At The Drawing

003: Base

005: Bearing Assembly

132: Intake Joint, Discharge Joint

130: Discharge Flange, Intake Flange 013: Cover Plate

131: Bowl

137: Impeller

041:Back Liner

135: Door Clamp Ring

134: Adapter Plate Clamp Ring

124: Volute Cover Seal

Related Products

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.