Gravity Separation Equipment

Cost-Effective Gravity Concentration Solutions, Mineral Recovery Rate of 95%+ Guaranteed.

- High efficiency and durability

- 90%+ Recovery Rate

- Energy saving & Eco-friendly

Mineral Processing » Equipment » Gravity Separation equipment

Gravity Separation Equipment Supplier

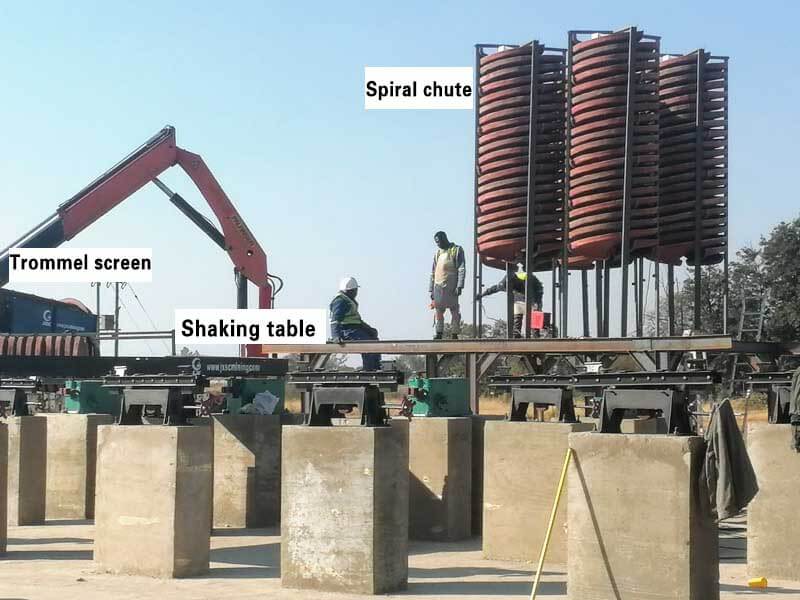

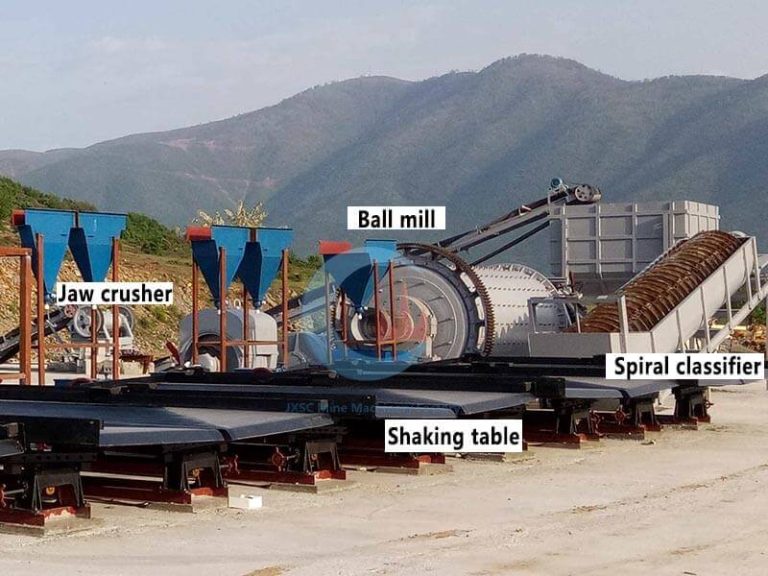

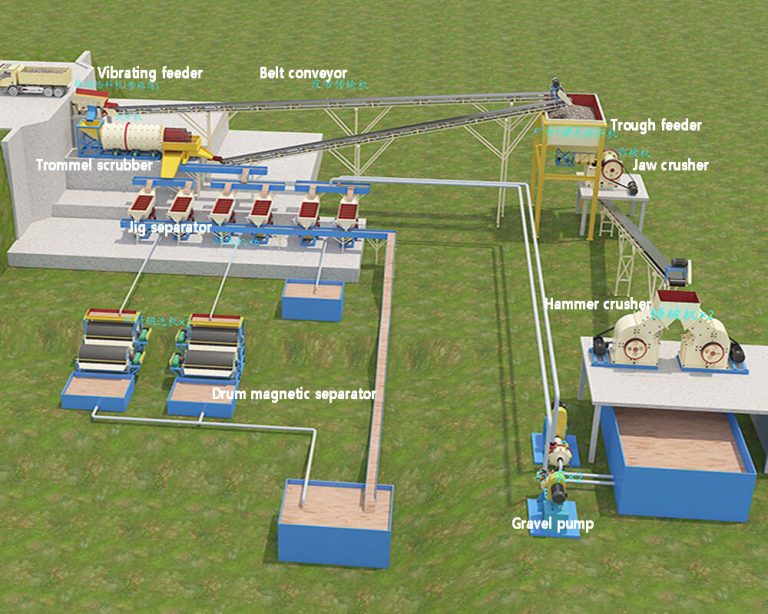

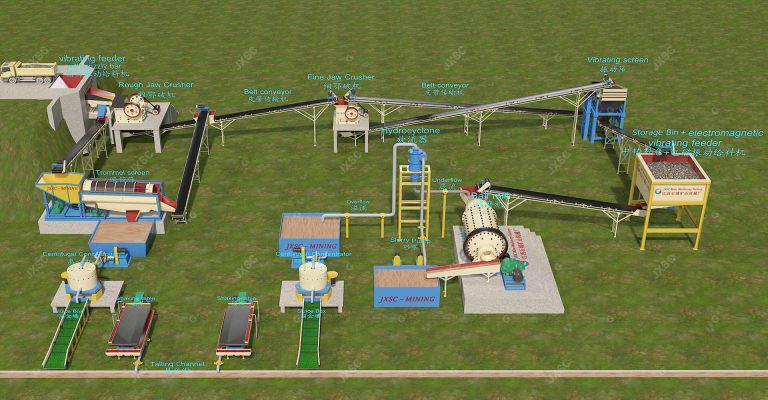

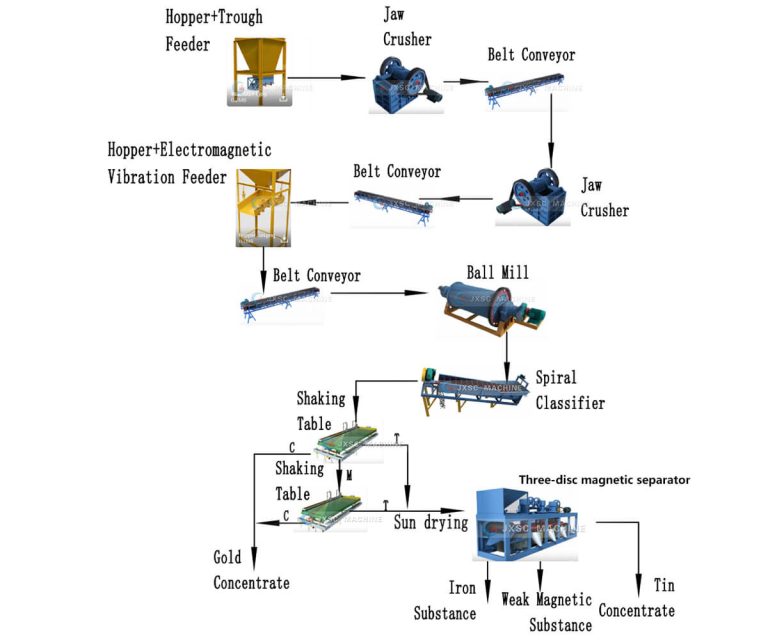

Gravity separation remains the most cost-effective mineral processing method for mines focusing on high-grade recovery. JXSC has more than 40+ years of experience in manufacturing mineral gravity separation equipment. All utilize physical forces such as gravity, water flow, or air flow to efficiently separate light and heavy minerals. Mainly includes jig separators (mineral jig machine), mobile jig concentrator plants (jig with trommel screen/rotary scrubber form small gold, diamond wash plant), Gemini shaker tables, shaking tables (gravimetric tables, concentrating table, gold shaker table), spiral chutes (spiral separators, spiral concentrators), and centrifugal concentrators. It is very suitable for fine and heavy mineral concentration operations such as ferrous metals, rare metals, and precious metal ores.

Types of Gravity Separation Equipment

mining jig machine

1-25t/h

Vibrating Sluice Box

20-30 m3/h

centrifugal concentrator

0.5-60 TPH

Gold sluice box

10-25TPH

spiral separator

0.15-10 t/h

PU spiral chute

0.8-4TPH

shaking table

10-20 t/d, Up to 60t/d

gravity separation equipment for sale

Gravity separation equipment, referred to as a mining gravity separator, uses the difference in specific gravity between different minerals and separates different minerals with the help of gravity or centrifugal force to achieve the best mineral processing effects. Mainly include jig separators, gold shaker tables, spiral chutes, and centrifugal concentrators. It can effectively process coarse-grained, medium-grained, and fine-grained ores with little mud. JXSC is committed to continuously optimizing machine performance to provide customers with efficient and reliable gravity concentration equipment, with a 95%+ ore recovery rate. Contact JXSC for more mining gravity separator details and the latest price!

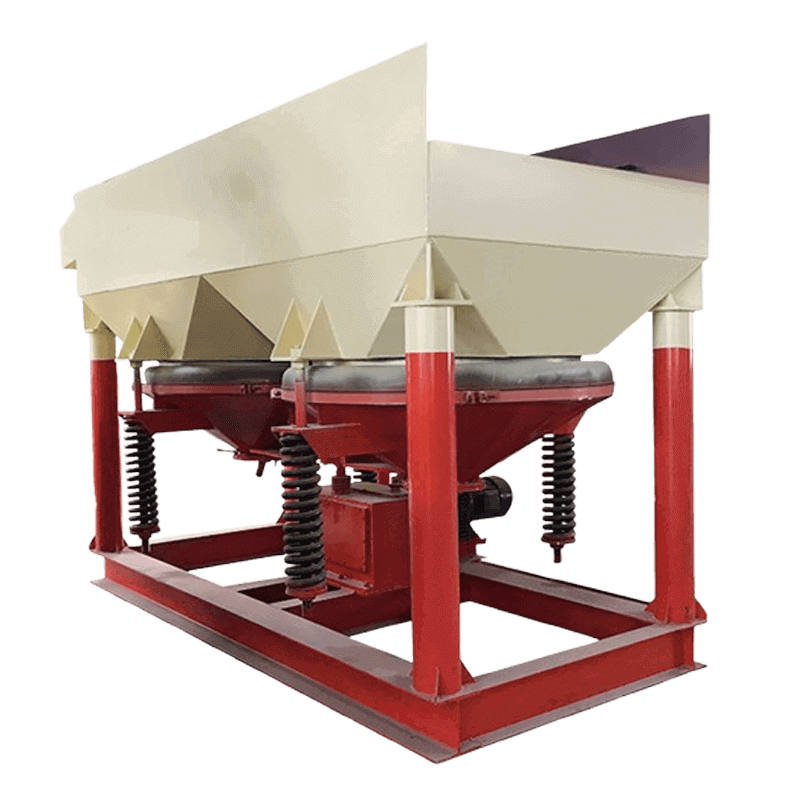

Jig Separator

Capacity: 1-25t/h

The jig concentrator is suitable for processing gold, diamond, Ta-Nb-tin, coltan, fluorite, tungsten, and manganese ore.

♦ Perfect for coarse-grained mineral enrichment.

♦ Automated adjustment, low sorting costs.

♦ wide granularity adaptation and eco-friendly.

Shaking Table

Capacity: 10-20 t/d, Up to 60t/d

A high-precision shaker table is used for gold, copper, tantalum-niobium, tin, chrome, beach sand, and iron ore separation.

♦ Customizable optionals: large 2-layer/ 4-layer, or small lab shakers. 90%+ concentration rate.

♦ Easy adjustment, durable bed surface.

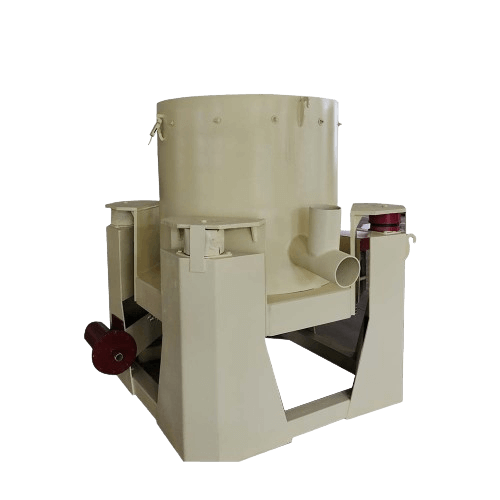

Gold centrifugal Concentrator

Capacity: 0.5-60 TPH

The centrifugal concentrator is ideal for concentration and recovery of gold from placer gold, vein gold and polymetallic ores.

♦ High-speed recovery with minimal losses.

♦ Continuous output of concentrate and tailings.

♦ Extremely efficient, stable operation, low cost.

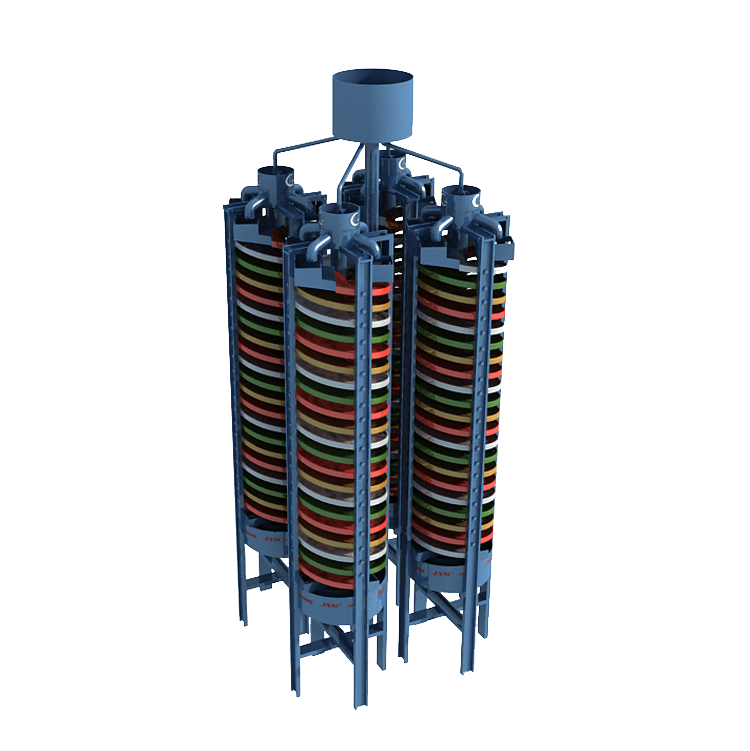

Spiral Chute

Capacity: 0.15-10 t/h

Spiral separator is suitable for silica sand, zircon sand, titanium ore, chrome, cobalt ore, rutile, or other mineral sand separation.

• Small footprint, large processing capacity.

• High enrichment ratio and recovery rate.

• Moisture-proof, rust-proof, corrosion-resistant.

Mobile Jig Concentrator

Capacity: 1-20 TPH

Mounted small trommel screen or trommel scrubber with jig; One-stop gold and diamond washing processing plant.

• low water consumption and energy-saving.

• Fast deployment, modular gold/diamond plant.

• Integrated washing, screening, and separating.

Gemini Shaker Table

Capacity: 0.1-1.2t/h

The shaking table has a good effect on gold concentrate recovery rate.

• Large enrichment ratio and sorting precision .

• Unique design, low energy and maintenance.

• Adjustable, high-quality components and durable materials, long service life.

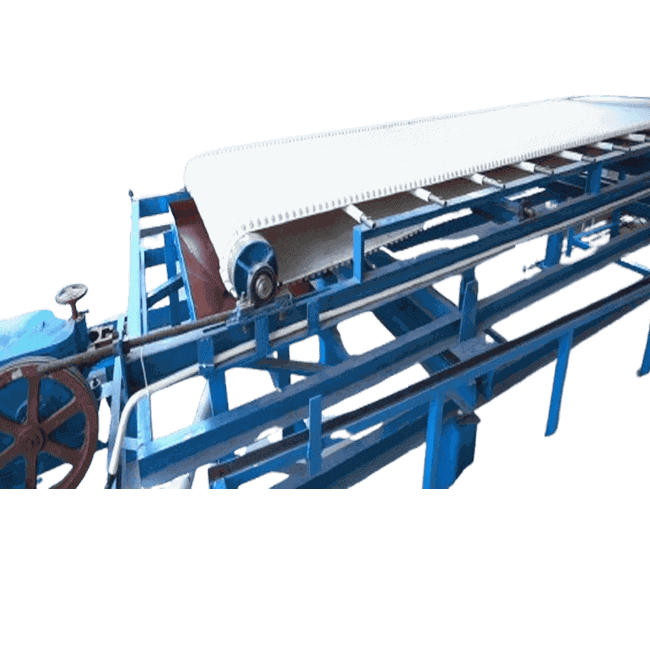

Vibrating Sluice Chute

Capacity: 20-30 m3/h

Application: The pulsating gold sluice box widely used to extract gold from sand after ore washing machine; it can also be installed on the excavation tools of sand dredging ships.

suspended vibration cone concentrator

Capacity: 8-15 Ton Per Day

Application: Mainly used for the separation of fine-grained minerals such as gold, lithium, tantalum, tungsten, tin, copper, etc.

Vibration Tailings blanket recycling machine

Capability: 1.5-2.5t/h

Application: A new and unique gold tailings gravity separator, and used for purification of tailings such as tungsten, tin, copper, lead, zinc, etc.

Why choose JXSC gravity separation equipment

Advantages of mining gravity separator

Utilizing advanced gravity separation technology, it effectively captures fine-grained minerals, increasing metal recovery rate by 15% compared to traditional equipment, significantly enhancing the economic value of the ore.

Optimized fluid dynamics design reduces operating power; a closed-loop water circulation system reduces water consumption, resulting in an 80% reduction in wastewater discharge. This significantly saves on electricity and water bills. This not only meets eco-friendly requirements but also reduces long-term production costs and increases corporate profit margins.

The robust steel frame structure, wear-resistant materials, and modular design ensure long-term stable operation with a failure rate of less than 1%, significantly reducing unexpected downtime. It maintains efficient sorting even under harsh working conditions.

The parameters of centrifugal concentrators, jigs, shaking tables, and spiral chutes can be flexibly adjusted. Whether it's precious metals, non-ferrous or ferrous metals, or tailings, meets various mineral processing needs, such as gold, copper, chromite, manganese, tin, tungsten, etc.

Precise vibrating table adjustment and fluid control technology effectively reduce mixed impurities and improve concentrate grade. The stable sorting results make downstream beneficiation or sales more competitive and allow for higher product premiums.

Key components are made of wear-resistant tungsten carbide material, extending their lifespan by two times. The equipment is equipped with an intelligent early warning system that can predict malfunctions 72 hours in advance. Maintenance time is reduced by more than 50%, significantly lowering labor costs and ensuring smoother production.

Maximize Your Mineral Recovery Rates

Our gravity separation equipment boasts high-precision sorting, intelligent, and energy-saving & eco-friendly as its core advantages, providing you with a high-yield, low-investment, and sustainable mineral processing solution! Through our unique modular design, it can be adapted to coarse, medium, and fine-grained minerals, achieving a recovery rate of 95%+ while reducing energy consumption. Currently, our gravity separation machines have been exported to 40+ countries, including South Africa, Zimbabwe, Zambia, Senegal, Nigeria, Rwanda, Mali, Uganda, Colombia, Angola, Indonesia, Ghana, Tanzania, Mozambique, Brazil, Ethiopia, Kenya, and Congo, for use in mining operations.

Whether you need a standard model or a customized gravity concentration solution, JXSC can provide full support from selection to installation, ensuring that the equipment is 100% matched to your ore characteristics.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.