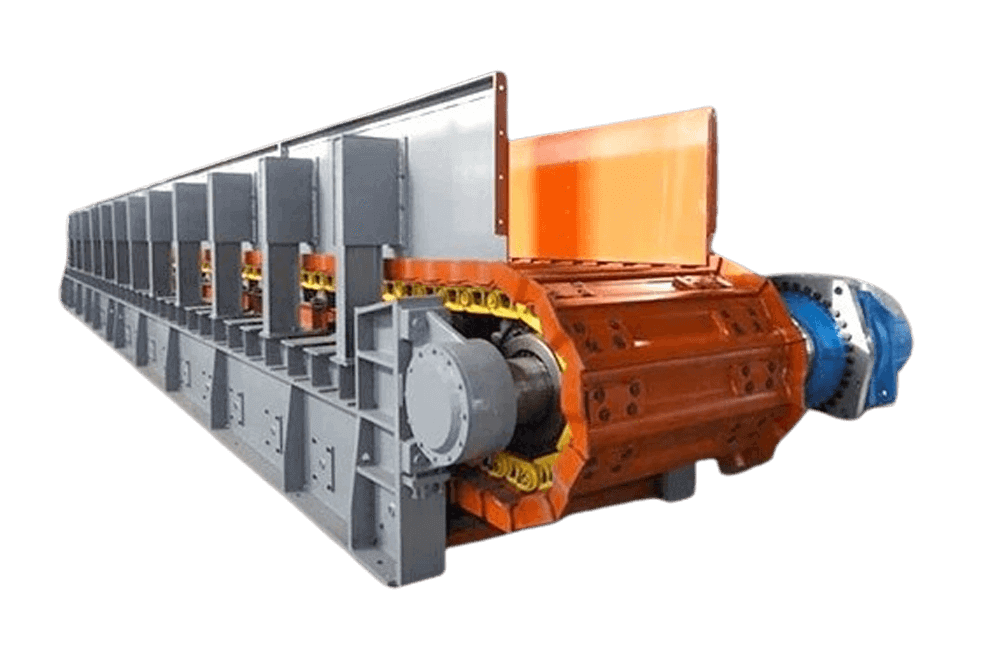

Heavy Duty Apron Feeder

Feeding Capacity: 100-400m³/h

Application: Heavy duty apron feedes are widely used in building materials, metallurgy, mining, crushing line, cement production and other industries; suitable for conveying and feeding rock aggregates or ores such as gold, copper, iron ore, limestone, river pebbles, granite, basalt, quartzite, or heavy construction waste.

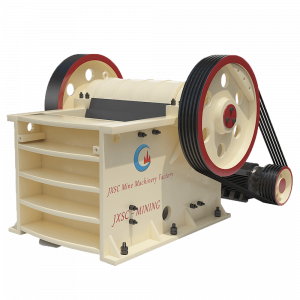

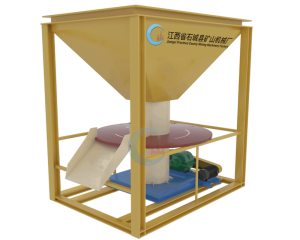

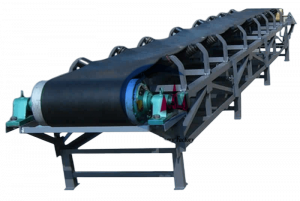

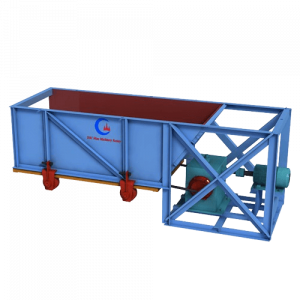

Products display

Introduction of Heavy duty apron feeder

Heavy duty apron feeder, also called heavy plate feeder, is a feeding device designed for conveying larger, extremely heavy or abrasive bulk materials. It can also be used to transport materials with various block sizes and densities from the warehouse to the crusher, conveyor or other working machinery in a horizontal or inclined direction. This feeder also adopts a rugged design and heavy-duty components, such as large rollers or sprockets, which can withstand the extreme impact forces caused by heavy mining and industrial operations and have a strong load-bearing capacity.

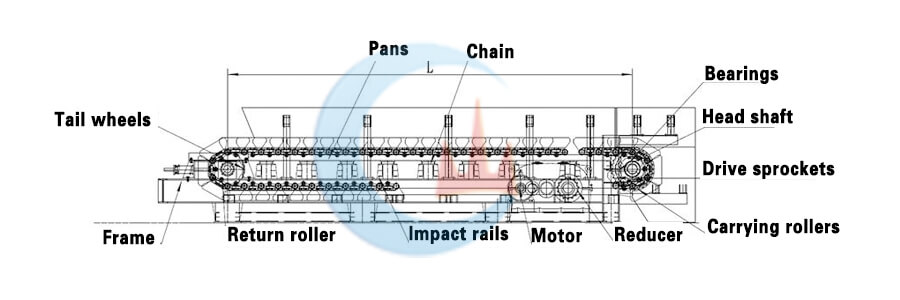

Working principle of heavy duty apron feeder

Heavy-duty plate/apron feeder is composed of a frame, a rotary body, a drive device, a chain support roller, a lower support roller, and a head cover. The walking track is the key component of the machine. It mainly drives the chain plate above to move by driving the sprocket to rotate with the power of the motor. The chain plate adjusts the tensioning device to make the chain and sprocket perfectly toothed, and drives the slot plate to transport the feed.

Why Choose JXSC Heavy Duty Apron Feeder

Features & advantages Of Heavy Duty Apron Feeder

1. This heavy plate feeder is wider than ordinary plate feeders, it can achieve greater capacity and more effectively handle heavy or bulk materials;

2. The feeder has greater applicability to material types, temperatures, viscosities, etc., and a wide range to meet different production volume requirements;

3. It is composed of a series of overlapping discs or plates, made of high-strength steel or other wear-resistant materials, with long service life and low maintenance costs;

4. Heavy duty apron feeder can adapt to load start-up and variable incoming material conditions, and can also be used to transport materials in high temperature, high humidity or extreme environments;

5. The feeder has a large processing capacity, and the speed can be adjusted through the frequency conversion control cabinet, stable operation, and easy operation.

models & specifications

/ | Scraping Belt | Feeding Capacity | Motor Power | Weight | Overall Dimensions | ||

Model | Width(mm) | Center distance of sprocket (mm) | Speed(m/s) | (m³/h) | (kw) | (kg) | (mm) |

GBZ120-4.5 | 1200 | 4500 | 0.05 | 100 | 15 | 31279 | 6983×5228×2080 |

GBZ120-5 | 5000 | 33427 | 7593×5228×2080 | ||||

GBZ120-5.6 | 5600 | 34321 | 8183×5228×2080 | ||||

GBZ120-6 | 6000 | 35900 | 8638×5228×2080 | ||||

GBZ120-8 | 8000 | 22 | 41342 | 10533×5293×2080 | |||

GBZ120-8.7 | 8700 | 43164 | 11383×5293×2080 | ||||

GBZ120-10 | 10000 | 46962 | 12583×5293×2080 | ||||

GBZ120-12 | 12000 | 51844 | 14653×5293×2080 | ||||

GBZ120-15 | 15000 | 30 | 62157 | 17658×5518×2080 | |||

GBZ150-4 | 1500 | 4000 | 150 | 15 | 33197 | 6613×5528×2080 | |

GBZ150-6 | 6000 | 22 | 39257 | 8638×5593×2080 | |||

GBZ150-7 | 7000 | 43352 | 9633×5593×2080 | ||||

GBZ150-8 | 8000 | 45962 | 10533×5593×2080 | ||||

GBZ150-9 | 9000 | 30 | 50522 | 11683×5668×2080 | |||

GBZ150-12 | 12000 | 45 | 59915 | 14653×5888×2080 | |||

GBZ180-8 | 1800 | 8000 | 240 | 45 | 51360 | 10533×6188×2080 | |

GBZ180-9.5 | 9500 | 57397 | 12033×6188×2080 | ||||

GBZ180-10 | 10000 | 59632 | 12593×6188×2080 | ||||

GBZ180-12 | 12000 | 66029 | 14653×6188×2080 | ||||

GBZ240-4 | 2400 | 4000 | 400 | 30 | 44780 | 6613×6718×2080 | |

GBZ240-5 | 5000 | 50737 | 7533×6718×2080 | ||||

GBZ240-5.6 | 5600 | 52447 | 8133×6718×2080 | ||||

GBZ240-10 | 10000 | 45 | 76373 | 12593×6718×2080 | |||

GBZ240-12 | 12000 | 853 | 14653×6718×2080 | ||||

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.