Jaw Crusher

Types of jaw crusher: PE, PEX, PEV (European).

Capacity: 1-1120t/h

Feeding size: <800mm

Output size: <10-360mm

Application: The jaw crusher is used for coarse or fine crushing of high hardness ores, such as gold, copper, manganese, tin, iron, chrome, lithium, lead-zinc, river pebbles, marble, calcite, limestone, basalt, quartz stone, or other mineral or rock primary crushing stage.

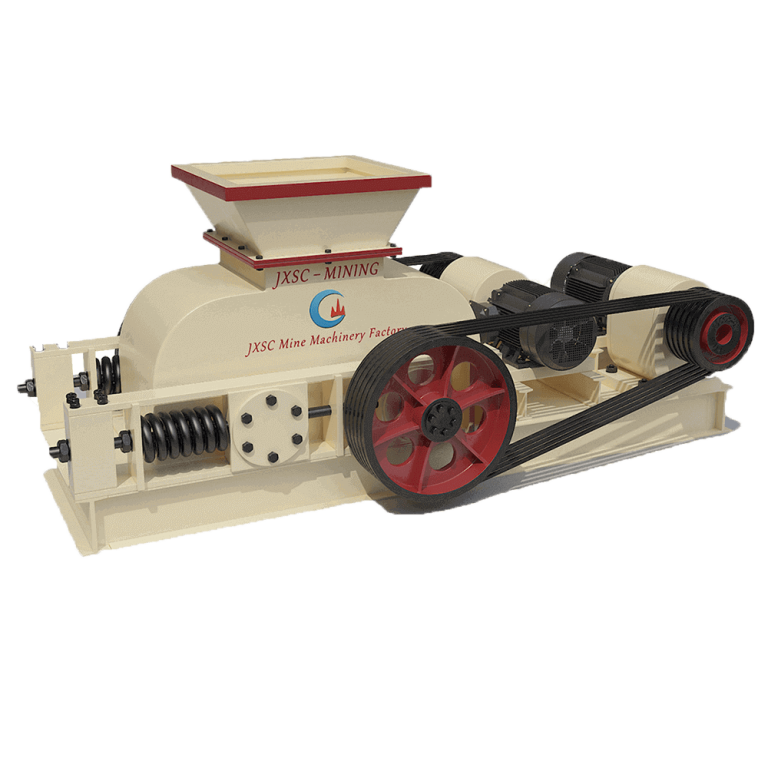

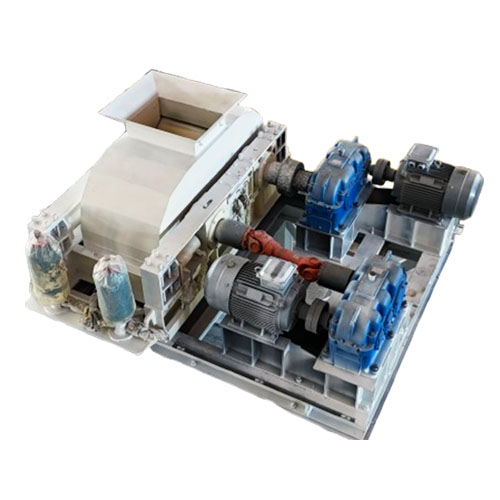

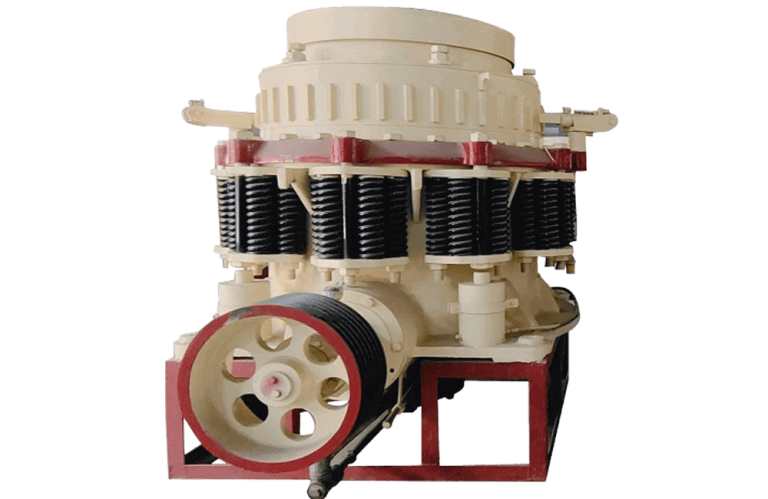

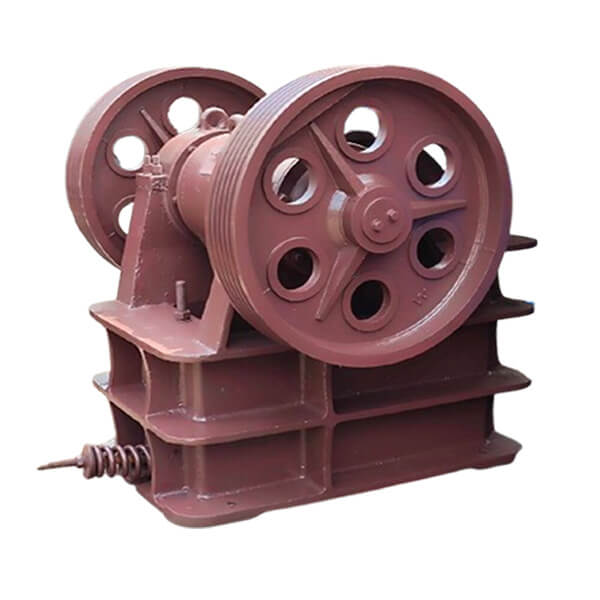

Products display

Introduction of Jaw Crusher

Jaw crusher is a robust size reduction crushing equipment designed to reduce large solid materials into smaller particles, widely used in the quarrying, metallurgical, and allied industries. It is one of the most commonly used primary or coarse (PE series) and medium, fine crushers (PEX series) in the ore processing plant, with a capacity range of 1-1000tph. There are two types of feeding opening designs, rectangular and square shape. JXSC also provides multiple models or customized fixed or mobile type jaw crushers to meet various processing needs of users. The jaw crusher is the core equipment for primary crushing of mineral processing due to its durability, efficient coarse crushing and high adaptability. Applicable to crush various materials with high hardness and compressive strength ≤320MPa, typically including: metal ores (iron ore, copper ore, gold ore, Manganese, lead-zinc, chrome, lithium, etc.); sand and gravel aggregates (granite, basalt, pebbles, etc.); construction waste (concrete, bricks, asphalt blocks); industrial solid waste (slag, coal gangue).

It also provides raw materials with suitable particle size for subsequent secondary crushing, fine crushing or grinding processes. In addition, the jaw crusher has a large feed opening, high crushing ratio, strong adaptability, and can handle materials of various hardness and sizes. Therefore, the PE (coarse crushing) and PEX (fine crushing) series jaw crushers occupy an important position in the fields of sand and gravel aggregates, mine crushing, solid waste treatment, etc. Due to its simple structure and convenient maintenance, the jaw crusher is also regarded as the preferred crushing equipment “first checkpoint” for sand and gravel aggregate production lines and mines.

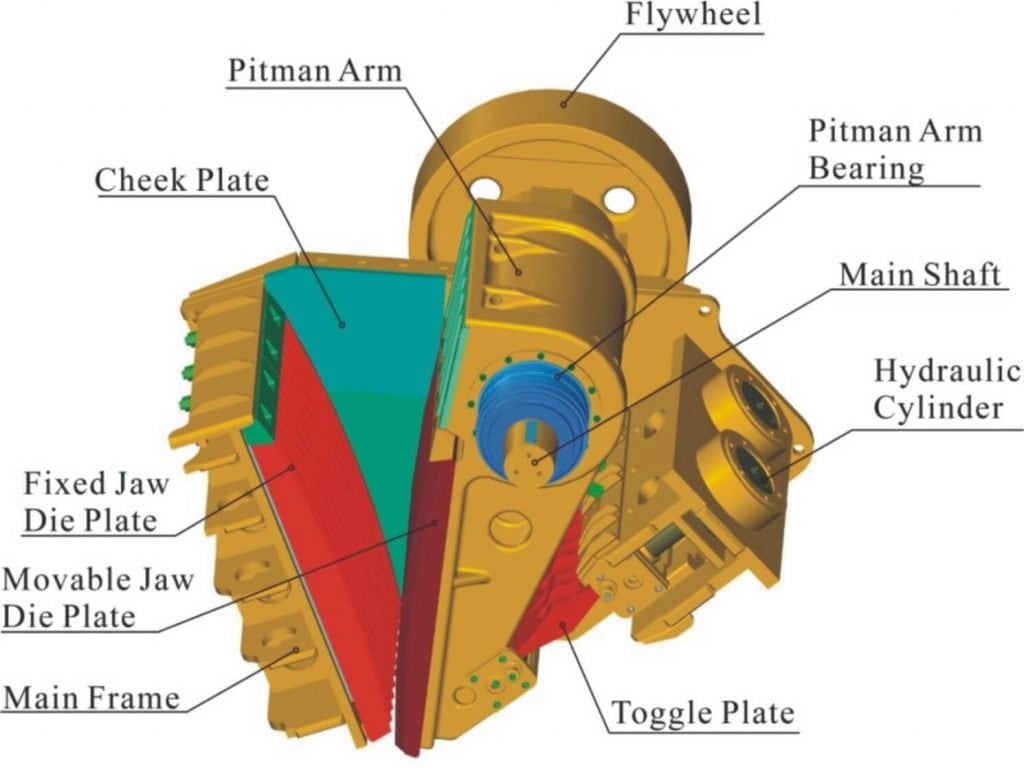

Working principle Of jaw crusher

The working principle of the jaw crusher is mainly to crush materials through the periodic movement of the movable jaw. The motor drives the belt and pulley to move the jaw plate up and down through the eccentric shaft. When the movable jaw rises, it pushes the movable jaw plate closer to the fixed jaw plate. At the same time, the material is squeezed, rubbed, rolled and crushed in multiple ways. When the angle with the movable jaw plate becomes smaller, the materials are discharged from the lower opening of the crushing chamber. With the motor’s continuous rotation, the crusher’s jaw plate is crushed and discharged regularly to achieve mass production.

Types of jaw crushers

Traditional jaw crushers adopt two structures: compound swing type (PE series) and simple swing type (PEX series). The new generation of European jaw crushers features a welded frame and an advanced adaptive hydraulic system, further enhancing equipment performance and lifespan.

Capacity: 1-1120t/h

The PE series is a coarse jaw crusher, suitable for primary crushing and bulk material crushing in large mines. Such as the first coarse crushing of high-hardness materials (such as iron ore, copper ore, lithium, gold, lead-zinc).

It adopts the classic double-toggle plate simple pendulum structure, the movable jaw suspension shaft is located at the rear of the equipment, and the motion trajectory is a standard arc shape. It has a sturdy structure, strong impact resistance, and a large feed opening.

Capacity: 1-120t/h

The PEX series is a fine crushing jaw crusher, suitable for fine crushing and sand making of medium-hard materials. Such as the second crushing stage of mineral processing, cement aggregate, machine-made sand production, etc.

It adopts a single-toggle plate compound pendulum structure, the upper part of the movable jaw is directly suspended on the eccentric shaft, the motion trajectory is elliptical, and has a stronger grinding effect. Its motion trajectory is optimized, the crushing ratio is high, and the finished product is more uniform.

The European version series is an energy-efficient crusher that combines German crushing technology with modern industrial design concepts. It adopts a welded frame and modular design. Compared with traditional PE/PEX models, it is lighter and stronger, suitable for more severe working conditions. The European version is widely used in large mines and high-standard aggregate production. Its main features are:

- Hydraulic adjustment of the discharge port: more precise and time-saving adjustment.

- Automatic protection system: automatic reset when overloaded.

- Optimized deep cavity design: crushing efficiency +20%.

JXSC jaw crusher has developed various series, such as PE series (coarse crushing), PEX series (fine crushing), CJ European version jaw crusher (high efficiency and energy saving type), etc., which can meet the needs of production lines of different scales. Among them, the PE series is suitable for coarse crushing, and the PEX series is suitable for medium and fine crushing. The crushing ratio of PE is 4-6, and that of PEX can reach 8-10, with higher crushing efficiency. As the core equipment of the crushing industry, modern jaw crushers have developed into a high-tech product integrating efficient crushing, intelligent control, and green environmental protection. Contact us to customize according to the characteristics of your materials.

why choose JXSC jaw crusher

features & Advantages

√ Advanced crushing process:

It adopts a symmetrical “V” shape structure, commonly known as “Tiger’s Mouth”; the deep cavity crushing has no dead zone, and the materials will not block the crushing cavity, which improves production efficiency and has load-bearing solid capacity.

√ High wear resistance of parts:

The movable jaw is made of high-quality steel castings, and the eccentric shaft is made of forged blanks, etc., which increases the reliability of the equipment, is efficient, durable and has a long service life.

√ Stable performance and energy-saving:

It has a simple structure, easy maintenance and overhaul, and low operating costs; it consumes less energy, has low noise, and has less dust, creating a good production environment.

√ Wide range of applications:

The jaw crusher is the most widely used and is fully suitable for various sand and gravel, aggregate processing, mineral crushing plants, etc. The wide adjustment range of the discharge port increases the flexibility of the equipment.

√ Flexible Configuration:

JXSC can customize various types of jaw crushers and can also be equipped with feeders, vibrating screens, or other crushers to form a one-stop mobile crushing plant.

models & specifications

| Model | Feeding size(mm) | Max feeding size(mm) | Discharging size(mm) | Capacity (t/h) | Motor power(kw) | Weight (t) | Overall dimension (LxWxH)(mm) |

| PE-150*250 | 150*250 | 130 | 10-60 | 3-15 | 5.5 | 2.2 | 1000x1450x900 |

| PE-250*400 | 250*400 | 210 | 20-80 | 5-20 | 15 | 2.8 | 1450x1315x1296 |

| PE-400*600 | 400*600 | 340 | 40-100 | 16-60 | 30 | 6.65 | 1565x1732x1586 |

| PE-500*750 | 500*750 | 425 | 50-100 | 40-110 | 55 | 11.73 | 1890x1916x1870 |

| PE-600*900 | 600*900 | 500 | 65-180 | 80-180 | 55-75 | 16.13 | 2305x1840x2298 |

| PE-750*1060 | 750*1060 | 630 | 80-180 | 110-320 | 90-110 | 28 | 2450x2472x2840 |

| PE-800*1060 | 800*1060 | 680 | 100-200 | 140-340 | 90-110 | 30 | 2610x2556x2800 |

| PE-870*1060 | 870*1060 | 750 | 170-270 | 180-360 | 90-110 | 31.22 | 2660x2556x2800 |

| PE-900*1060 | 900*1060 | 780 | 200-290 | 200-380 | 90-110 | 31 | 2690x2556x2800 |

| PE-900*1200 | 900*1200 | 780 | 95-225 | 220-450 | 110-132 | 49 | 3335x3182x3025 |

| PE-1000*1200 | 1000*1200 | 850 | 195-280 | 280-550 | 110-132 | 51 | 3435x3182x3025 |

| PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 400-800 | 160-220 | 100.9 | 4200x3732x3843 |

| PE-1500*1800 | 1500*1800 | 1200 | 210-360 | 525-1120 | 280-335 | 132 | 5100x4700x4300 |

| PEX-150*250 | 150*250 | 125 | 10-40 | 1-3 | 5.5 | 2 | 896x745x935 |

| PEX-150*750 | 150*750 | 120 | 18-48 | 8-25 | 15 | 3.5 | 1380x1658x1025 |

| PEX-250*750 | 250*750 | 210 | 25-60 | 13-35 | 30 | 4.96 | 1545x1667x1330 |

| PEX-250*1000 | 250*1000 | 210 | 25-60 | 16-52 | 30-37 | 6.5 | 1530x1992x1380 |

| PEX-250*1200 | 250*1200 | 210 | 25-60 | 20-61 | 37-45 | 8.52 | 1900x2192x1430 |

| PEX-300*1300 | 300*1300 | 250 | 20-90 | 25-95 | 55-75 | 12.6 | 1750x2320x1724 |

| PEX-350*1200 | 350*1200 | 300 | 70-140 | 25-120 | 75 | 12.35 | 2162x2220x1723 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.