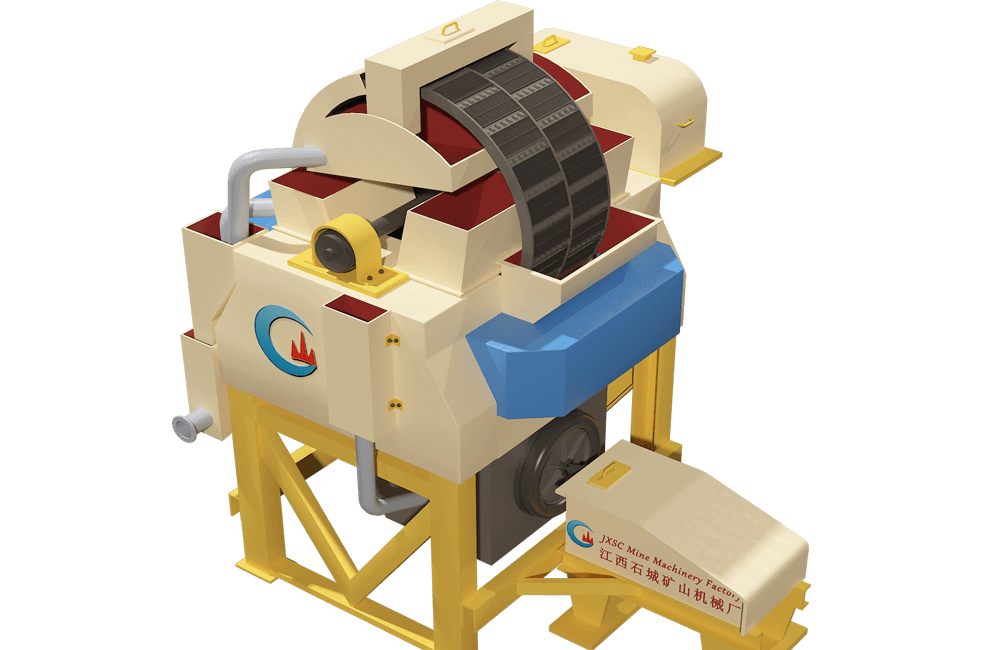

Vertical Ring Pulsating High Gradient Magnetic Separator

- Dry Ore Capacity (t/h): 0.01-150 tons per hour

- Feeding size: 0-1.2mm

Application: Vertical ring pulsating high gradient magnetic separator is commonly used for wet separation of weakly magnetic minerals such as hematite, chromite, limonite, vanadium-titanium magnetite, manganese and limonite; separation of black and white tungsten ore and tungsten-tin ore; it can also be used for impurity removal and purification of non-metallic minerals such as kaolin, feldspar, nepheline, garnet and quartz sand.

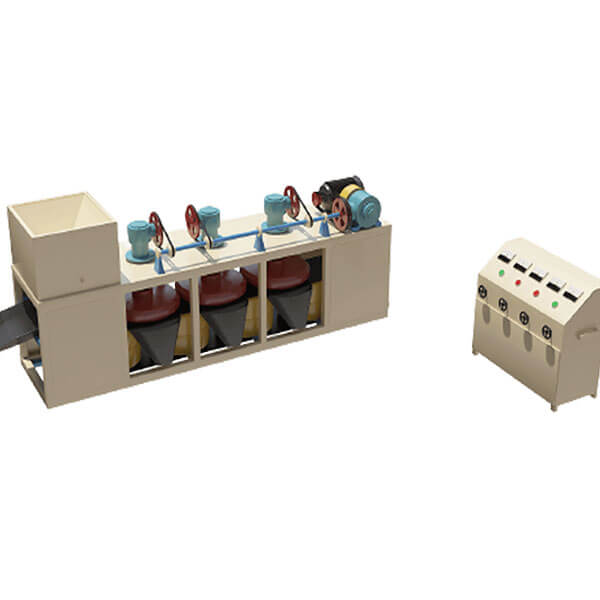

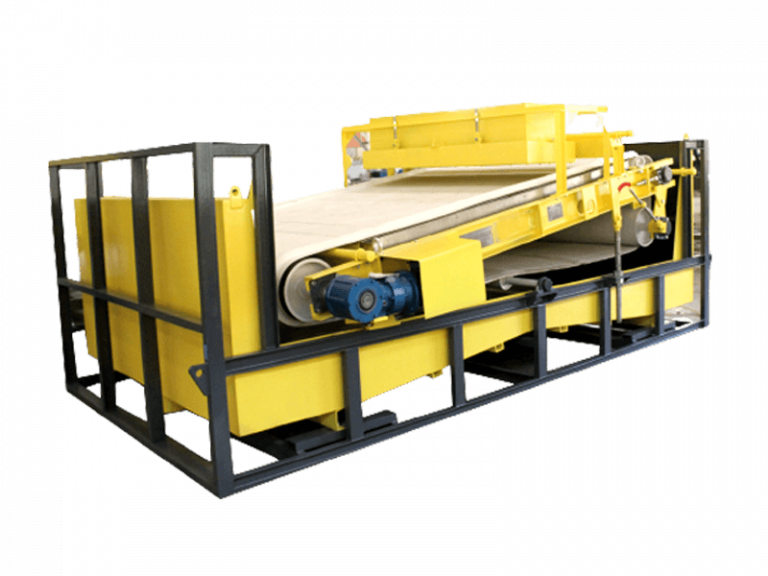

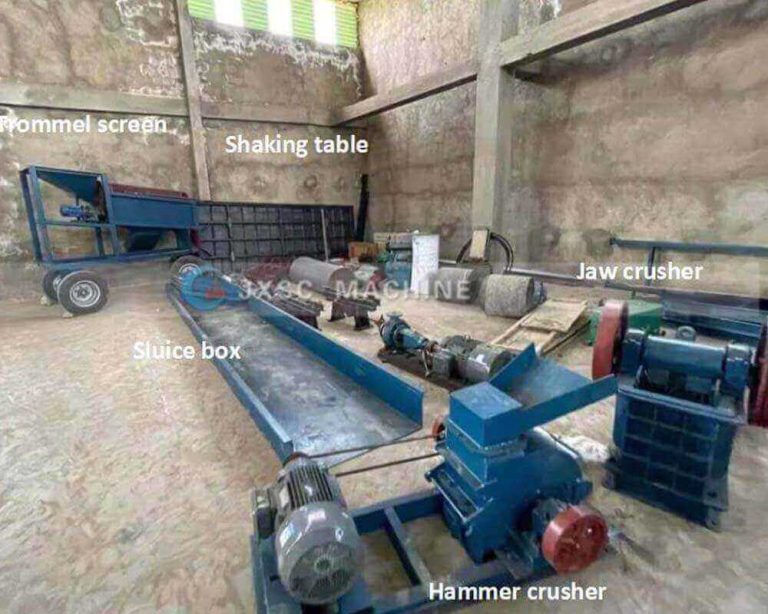

Products display

Introduction Of high gradient magnetic separator

Vertical ring pulsating high gradient magnetic separator, also known as vibrating high gradient strong magnetic separator or wet high intensity magnetic separator (WHIMS). It is a magnetic separation equipment with advanced technology and good performance. This high-gradient magnetic separator utilizes a rotating ring, recoil concentrate, and high-frequency vibration mechanism to prevent clogging of the magnetic medium, making it used for wet separation of various weak magnetic materials.

- Recovery rate ≥95%.

- Concentrate grade increased by 20-30%.

- Anti-clogging design.

It features high processing capacity, a high enrichment ratio, and strong adaptability. It is particularly suitable for the efficient separation of low-grade, fine-grained, weakly magnetic minerals in challenging separation scenarios such as hematite, ilmenite, rare earth ores, kaolin, and quartz sand. The core function is to purify, remove iron, enrich minerals, and improve the grade of concentrate and resource utilization.

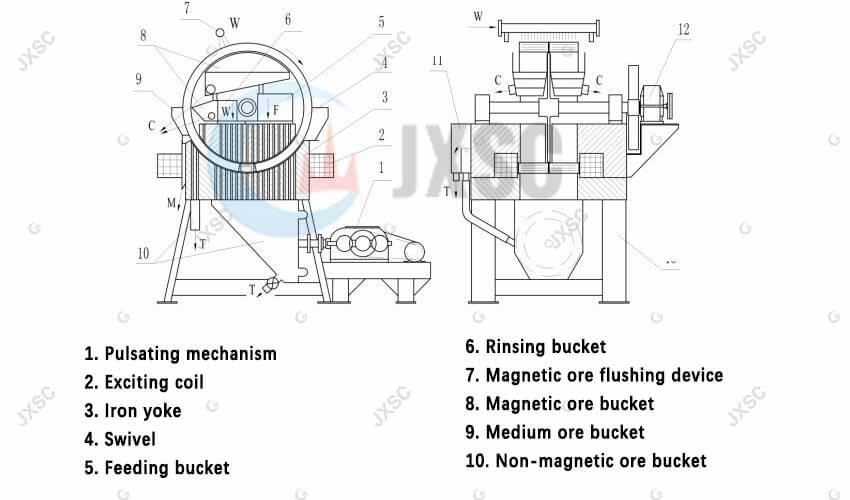

Principle and structure of high gradient magnetic separator

Working principle

The rotating ring rotates clockwise, and the slurry is fed from the feeding hopper in the middle of the vertical ring and flows through the rotating ring along the gap of the upper iron yoke. A high-gradient magnetic field is formed on the surface of the magnetic medium, and the magnetic particles are attracted to the medium and then taken out of the magnetic field and subsequently washed into the magnetic concentrate tank. Non-magnetic or less magnetic particles pass through the medium along the magnetic poles and reach the non-magnetic collection hopper.

Structural characteristics

It mainly consists of pulsating mechanism, excitation coil, iron yoke, rotating ring, magnetic medium, ore bucket, and flushing device.

- Magnetic system: Utilizes a neodymium iron boron multi-pole magnetic system.

- Magnetic media: Utilizes magnetically conductive stainless steel mesh rods or filamentary steel wool.

- Cleaning system: High-pressure water spray.

Swivel: Vertical rotating design with adjustable speed, lightweight, and low transmission load. - Intelligent control: Dynamically adjusts magnetic field gradient and flushing parameters based on feed ore grade.

why choose JXSC high gradient magnetic separator

Features & advantages Of High Gradient Magnetic Separator

1. It adopts the operation mode of vertical circulation and repeated washing of concentrate, which is not easily blocked and has a good separation index.

2. This high gradient magnetic separator has strong magnetic force and can effectively remove weak magnetic impurities in non-metallic ores.

3. The magnetic field gradient is large and adjustable, with high intensity, high grade of finished concentrate, and recovery efficiency up to 98%.

4. The vertical ring pulsating high gradient magnetic separator has high automation and wide feed particle size range, strong applicability.

5. The outer shell is made of moisture-proof, dust-proof, and corrosion-resistant materials, which can maintain high-efficiency performance continuously and stably.

models & specifications

The following parameters take quartz magnetic separation as an example:

| Model | Background Magnetic Field (T) | Feeding Material Size (mm) | Feeding Material Density | Dry Ore Capacity (t/h) | Pulp Throughout (m3/h) | Excitation Power (kW) | Swivel Power (kW) | Pulsating Power (kW) | Swivel Diameter (mm) | Water Consumption (m3/h) | External Dimensions |

| LH-500 | 0.6-1.4 | 0-1 | 10-30% | 0.01-0.05 | 0.25-0.5 | 6-20 | 0.18 | 0.55 | 500 | 0.65-1.4 | 1800*1400*1320 |

| LH-750 | 0.6-1.4 | 0-1 | 10-30% | 0.1-0.25 | 1-2 | 8-30 | 0.75 | 1.5 | 750 | 1.4-2.5 | 2000*1360*1860 |

| LH-1000 | 0.6-1.4 | 0-1.2 | 10-30% | 2-4 | 12.5-20 | 10-40 | 1.1 | 2.2 | 1000 | 8-12 | 2700*2000*2400 |

| LH-1250 | 0.6-1.4 | 0-1.2 | 10-30% | 5-10 | 20-50 | 12-50 | 1.5 | 3 | 1250 | 12-20 | 3200*2340*2700 |

| LH-1500 | 0.6-1.4 | 0-1.2 | 10-30% | 10-15 | 50-100 | 15.5-60 | 3 | 3 | 1500 | 20-30 | 3600*2900*3200 |

| LH-1750 | 0.6-1.4 | 0-1.2 | 10-30% | 15-20 | 75-150 | 23-72 | 4 | 4 | 1750 | 30-50 | 3900*3300*3800 |

| LH-2000 | 0.6-1.4 | 0-1.2 | 10-30% | 20-30 | 100-200 | 29-85 | 5.5 | 7.5 | 2000 | 50-100 | 4200*3550*4200 |

| LH-2500 | 0.6-1.4 | 0-1.2 | 10-30% | 45-60 | 200-400 | 37-98 | 11 | 11 | 2500 | 100-150 | 5800*5000*5400 |

| LH-3000 | 0.6-1.4 | 0-1.2 | 10-30% | 80-120 | 350-650 | 48-110 | 18.5 | 18.5 | 3000 | 150-250 | 7600*6500*7200 |

| LH-3600 | 0.6-1.4 | 0-1.2 | 10-30% | 100-150 | 500-750 | 72-180 | 30 | 30 | 3600 | 200-400 | 7700*6500*7600 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.