Single Cylinder Hydraulic Cone Crusher

Capacity: 35-715 TPH

Application: Single-cylinder hydraulic cone crusher is widely used in construction, cement, water conservancy, highway, railway, mineral processing and other fields; such as river pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, dolomite and other ores or rocks for medium, fine and ultra-fine crushing.

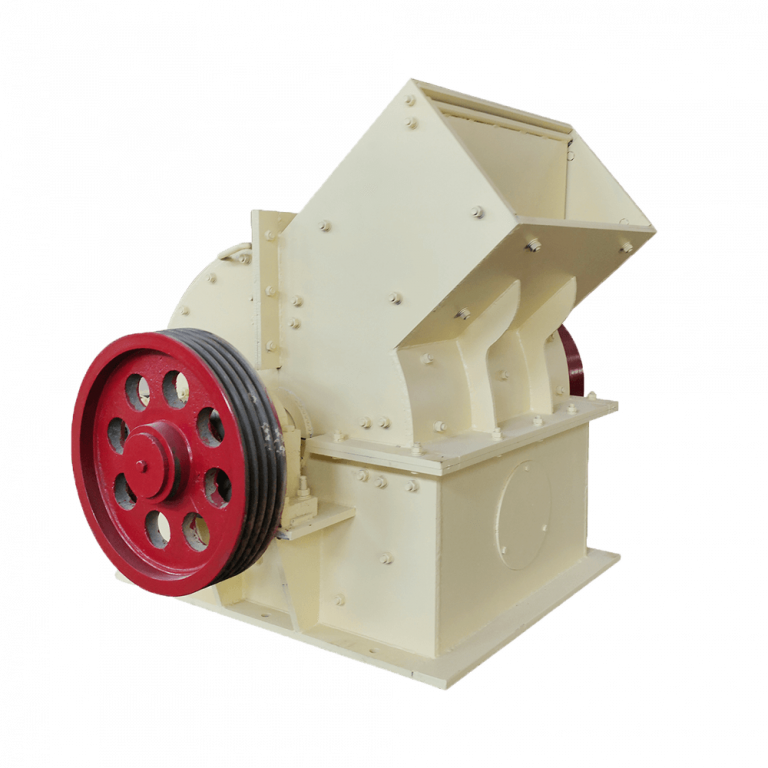

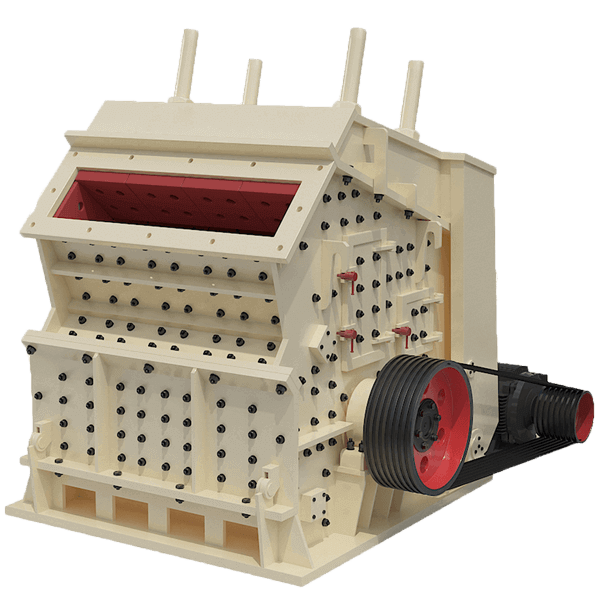

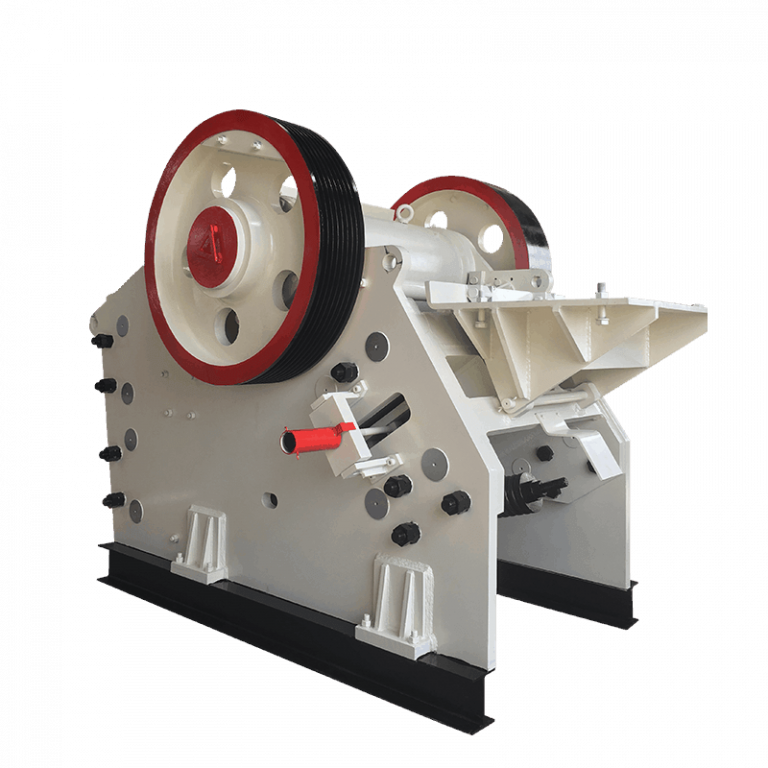

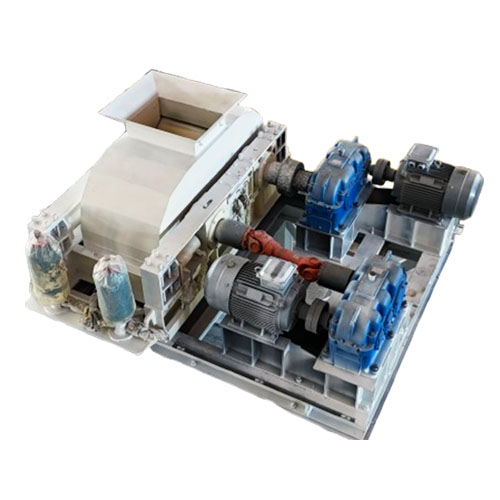

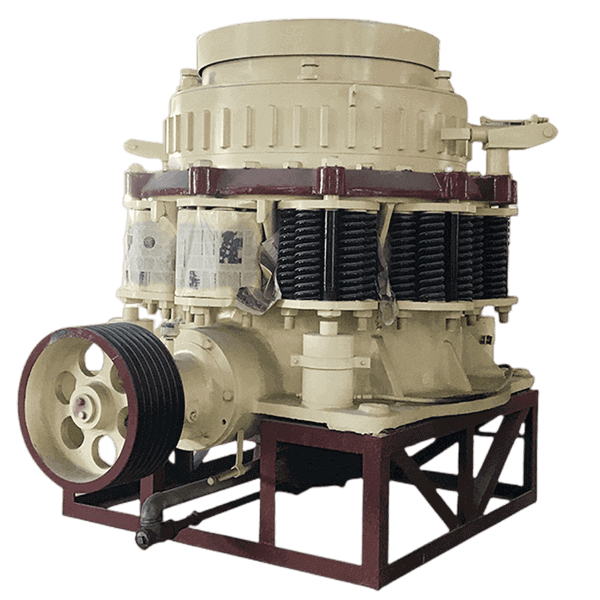

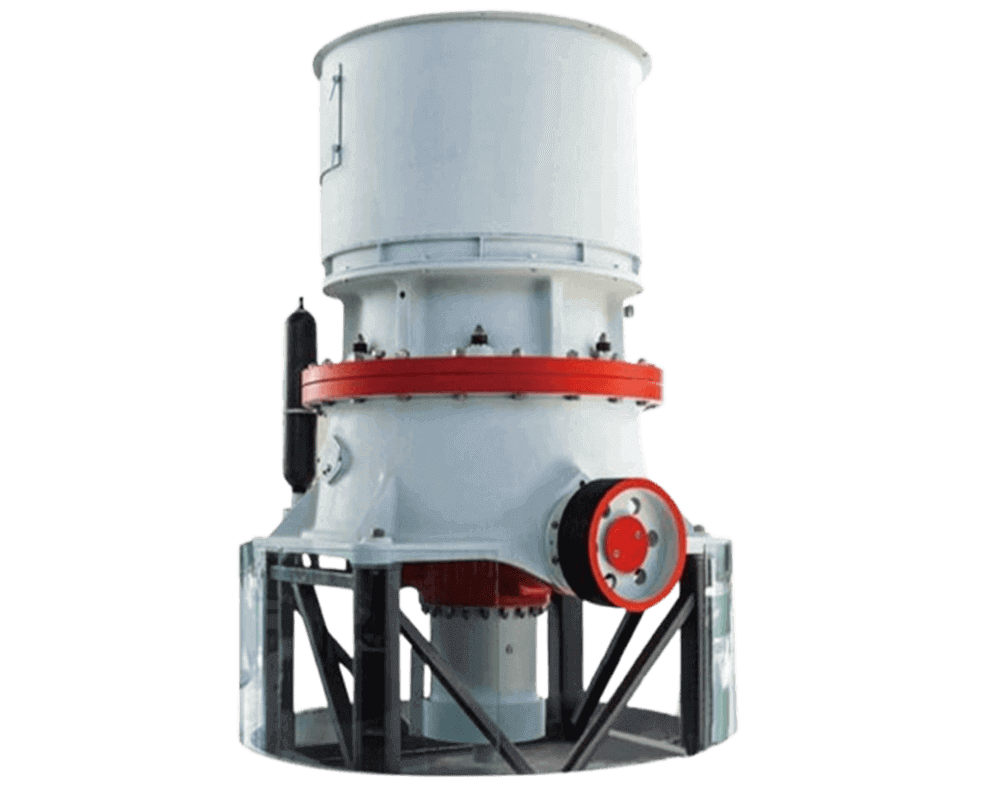

Products display

Introduction of Single Cylinder Hydraulic Cone Crusher

The single-cylinder hydraulic cone crusher is a high-efficiency crushing equipment that integrates mechanical, hydraulic, electrical, intelligent control and other technologies. It is often used for secondary, tertiary or quaternary crushing of ore, rock or other stone materials. It has a brand-new crusher structure, an optimized laminated crushing chamber and a fully intelligent automatic control system. At the same time, the particle shape of the crushed material is very excellent and the quality is even better. It adopts hydraulic drive and runs smoothly, which can effectively avoid the wear and impact of the traditional mechanical drive system, and improve the durability and work efficiency of the equipment. Therefore, the single-cylinder cone crusher is a highly recognized and favored crushing machine in the sand making, aggregate crushing or mineral processing industry.

The single cylinder hydraulic cone crusher is widely used in mining and mineral processing (fine crushing of metal/non-metallic ores), sand and gravel aggregates (processing of high-quality concrete aggregates), building materials (crushing of cement raw materials), and environmental protection (resource utilization of construction waste). JXSC supports customized fixed or mobile cone crushers (single-cylinder, multi-cylinder, Simmons); which are widely used in the processing of gold, diamonds, copper, iron ore, granite, basalt, and other materials. The single-cylinder cone crusher adjusts the height of the crushing chamber through the hydraulic system to adapt to a variety of crushing needs. It is one of the important crushing equipment in modern ore processing and building materials manufacturing.

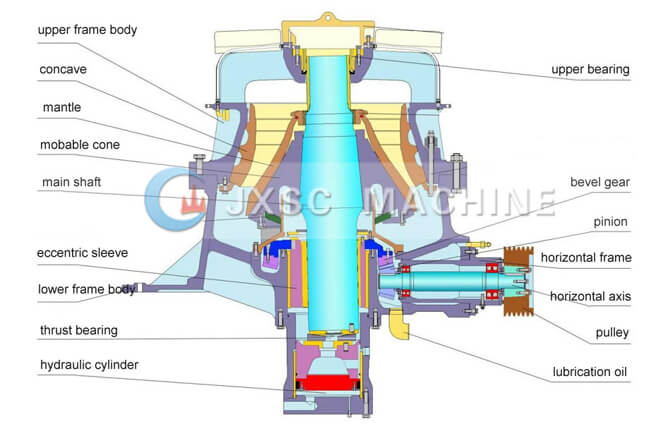

principle & structure of Single Cylinder Cone Crusher

Working principle

The material enters the crushing chamber of the single cylinder hydraulic cone crusher through the feed port. The crushing chamber is composed of the gap between the fixed cone and the moving cone. The material is crushed in this gap. The motor drives the transmission shaft of the equipment through the pulley and the V-belt, and the transmission shaft drives the eccentric sleeve to rotate through the large and small bevel gears. At this time, the main shaft installed in the eccentric sleeve drives the moving cone to rotate and swing with the rotation of the eccentric sleeve, so that the crushing wall is sometimes close to and sometimes away from the mortar wall. The material is constantly squeezed and impacted in the crushing chamber between the mortar wall and the crusher to achieve the purpose of crushing. The material is crushed and finally discharged.

Structural features

- Main frame: Made of high-strength steel, with pressure and shock resistance.

- Hydraulic system: Users can customize the width and height of the crushing chamber by adjusting the hydraulic cylinder to achieve adaptability to different materials.

- Crushing chamber: The crushing chamber formed between the moving cone and the fixed cone adopts an optimized design, with high crushing efficiency and good particle shape output.

- Feed port: Large size, convenient for the entry of large pieces of material, ensuring smooth feeding.

- Lubrication system: Equipped with an automatic lubrication system to ensure the stable performance of the machine under high load operation.

why choose JXSC Single Cylinder Hydraulic Cone Crusher

features & Advantages

1. The hydraulic and lubrication system with double insurance control can ensure the overload protection and good bearing lubrication of the machine;

2. Large production capacity, high crushing efficiency, stable operation, low noise and low energy consumption;

3. Adopting the principle of laminated crushing, a variety of optional chamber types, high crushing efficiency, and cubic product particle shape;

4. The vulnerable parts of JXSC single-cylinder cone crusher are made of highly wear-resistant materials, and the service life is guaranteed;

5. The automation level is high, and it can be flexibly adjusted according to the different characteristics of the material, suitable for medium and fine crushing of various ores;

6. The size of the discharge port can be accurately adjusted through the hydraulic system, thereby controlling the crushing particle size of the material.

7. The equipment is easy to install, compact in design, and small in installation space, which can effectively save infrastructure costs.

models & specifications

| Model | Chamber | Feeding opening (mm) | Max feeding size (mm) | Minimum discharge(mm) | Maximum discharge (mm) | Motor power | Machine weight | Capacity | ||||

| Stroke | Stroke | Stroke | Stroke | Stroke | Stroke | KW | KG | t/h | ||||

| DNGP100 | A | 150 | 120 | 12 | 15 | / | 39 | 37 | 90 | 5800 | 35-135 | |

| B | 130 | 105 | 10 | 11 | / | 33 | 31 | |||||

| C | 100 | 85 | 7 | 9 | / | 33 | 30 | |||||

| DNGP200 | A | 220 | 180 | 18 | 22 | / | 35 | 30 | 160-220 | 12300 | 85-350 | |

| B | 150 | 120 | 15 | 19 | / | 35 | 30 | |||||

| C | 80 | 60 | 9 | 12 | / | 35 | 30 | |||||

| DNGP300 | A | 230 | 190 | 20 | 25 | / | 45 | 40 | 250-280 | 16500 | 115-400 | |

| B | 150 | 125 | 17 | 20 | / | 45 | 40 | |||||

| C | 80 | 60 | 10 | 13 | / | 40 | 35 | |||||

| DNGP500 | A | 230 | 180 | 22 | 26 | 30 | 50 | 45 | 40 | 315 | 25800 | 245-500 |

| B | 150 | 125 | 19 | 22 | 26 | 48 | 43 | 38 | ||||

| C | 100 | 80 | 12 | 14 | 16 | 40 | 35 | 30 | ||||

| DNGP600 | A | 280 | 220 | 22 | 26 | 30 | 45 | 35 | 30 | 355 | 26700 | 280-715 |

| B | 150 | 125 | 19 | 22 | 26 | 45 | 35 | 30 | ||||

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.