Spiral Classifier

Capacity: 21-1785 t/24h (over flow); 145-23300t/24h(returned sand); Up to 150% spiral submergence

Spiral diameter: 500-3000mm; Single, double or triple pitch spirals are available

Application: Spiral classifier is often combined with a ball mill to form a closed-circuit cycle to divert ore sand; classification in the grinding circuit of all mineral processing plant, sand and gravel plant; and desliming and dewatering in sand washing operations.

Products display

Introduction Of Spiral Classifier

Spiral classifiers are the main classification equipment for various mineral processing plants. It is mainly used for ore classification, separation, screening, desliming, and dewatering in sand-washing operations. It is often matched with ball mill to form a closed circuit, such as pulp classification in the beneficiation process of iron ore, gold ore, copper ore, lithium ore, chromium ore, etc. The spiral classifier can also be used for wet separation or desludging of non-metallic minerals such as quartz sand, feldspar, barite, etc. It is suitable for mineral processing, coal washing, and the building materials industries. Such as classification and recovery of coal slime water, and particle size control of machine-made sand in sand and gravel production lines.

- The spiral centrifugal classifier has the advantages of strong continuous operation, large processing capacity, low energy consumption per unit output, and convenient maintenance. It can handle particles with a diameter of 1um-10mm.

- The horizontal spiral centrifugal classifier adopts the method of wet classification, and its processing capacity can reach 1~20 (m3 slurry) kg/h. It is widely used in minerals, metal powders, chemical raw materials, pigments, fillers, etc.

Types Of Spiral Classifiers: high weir single spiral and double spiral, submerged single spiral and double spiral.

- High weir spiral classifier is suitable for coarse particle classification, the maximum size of overflow is generally 0.4~0.15mm;

- Submerged spiral classifier is suitable for fine particle classification, the maximum size of overflow is generally below 0.2mm.

Its purpose is to separate coarse and fine particles to ensure qualified feed for subsequent mineral processing operations.

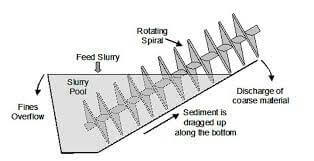

principle & structure of spiral classifier

Working Principle

The spiral classifier is based on the principle that the solid particles are different in size and specific gravity, so the settling speed in the liquid is different. Fine ore particles float in the water and overflow, and coarse ore particles sink to the bottom of the tank.

Spiral classifier is widely used in beneficiation plant to match with ball mill to form a closed circuit circulation path to distribute ore sand. Filter the material powder milled in the mill, and then use the spiral piece to screw the coarse material into the ball mill inlet, and the filtered fine material is discharged from the overflow pipe.

Structural features

- It consists of a wear-resistant spiral, an inclined trough, an intelligent drive system, and a lifting mechanism.

- The spiral blades are made of wear-resistant high-chromium alloy or rubber coating. The bottom is equipped with a sand discharge outlet (for coarse particles) and an overflow weir (for fine particles), both of which are height-adjustable.

why choose JXSC Spiral Classifier

features & Advantages Of Spiral Classifier

1. The energy consumption of spiral classifier is 50% lower than other classification equipment, and the output is also increased by 50%.

2. The water tank has a large slope, which is convenient for forming a closed-circuit ring grinding operation with the ball mill, and forms a self-flow sand return.

3. Simple operating process and stable working status, greatly reducing maintenance costs.

4. Its spiral structure can ensure a large enough settling area to extend the material suspension time, which is more conducive to the even distribution of materials during the classification process.

5. Users can adjust the parameters of the spiral classifier according to their needs, such as spiral speed, inclination and outlet size to achieve different classification requirements.

6. Compared with hydrocyclones, it does not require high-pressure pumping and reduces overall energy consumption by 20% to 30%.

7. It can be equipped with a water circulation system to achieve zero wastewater discharge and environmentally friendly operation.

models & specifications

| Model | Spiral diameter | Spiral Speed | Water tank | Process Capacity (t/24h) | Drive motor | Lift Motor | |||

| MM | r/min | L (mm) | W(mm) | Slope(°) | Over Flow | Returned Sand | kw | kw | |

| FG-5 | Φ500 | 9.2 | 3900 | 560 | 10.5°-14° | 21-75 | 145-260 | 3 | 0 |

| FG-7 | Φ750 | 7.8 | 5367 | 830 | 10.5°-14° | 65-154 | 255-564 | 3 | 0 |

| FG-10 | Φ1000 | 7 | 6500 | 1110 | 10.5°-14° | 85 | 473-1026 | 5.5 | 0 |

| FG-12 | Φ1200 | 5,6,7 | 6500 | 1372 | 10.5°-14° | 150 | 1145-1600 | 5.5 | 2.2 |

| FG-15 | Φ1500 | 2.5,4,6 | 8265 | 1664 | 14°-18.5° | 235 | 1140-2740 | 7.5 | 2.2 |

| FG-20 | Φ2000 | 5.4 | 8400 | 2396 | 14.5°-18.5° | 400 | 5940 | 15 | 2.2 |

| FG-24 | Φ2400 | 3.6,5.4,6.3 | 9160 | 2600 | 14°-18.5° | 580 | 6800 | 11/15 | 2.2 |

| FG-30 | Φ3000 | 3.17 | 12500 | 3200 | 14°-18.5° | 890 | 11650 | 22 | 4 |

| 2FG-12 | Φ1200 | 5,6,7 | 6500 | 2620 | 14°-10.5° | 300 | 2290-3200 | 5.5X2 | 2.2X2 |

| 2FG-15 | Φ1500 | 2.5,4,6 | 8265 | 3200 | 14°-18.5° | 460 | 2240-5360 | 7.5X2 | 2.2X2 |

| 2FG-20 | Φ2000 | 5.4 | 8400 | 4296 | 14.5°-18.5° | 800 | 11880 | 15X2 | 2.2X2 |

| 2FG-24 | Φ2400 | 3.6,5.4,6.3 | 9160 | 5040 | 14°-18.5° | 1160 | 13600 | 11X2/15X2 | 2.2X2 |

| 2FG-30 | Φ3000 | 3.17 | 12500 | 6300 | 14°-18.5° | 1785 | 23300 | 22X2 | 4X2 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.