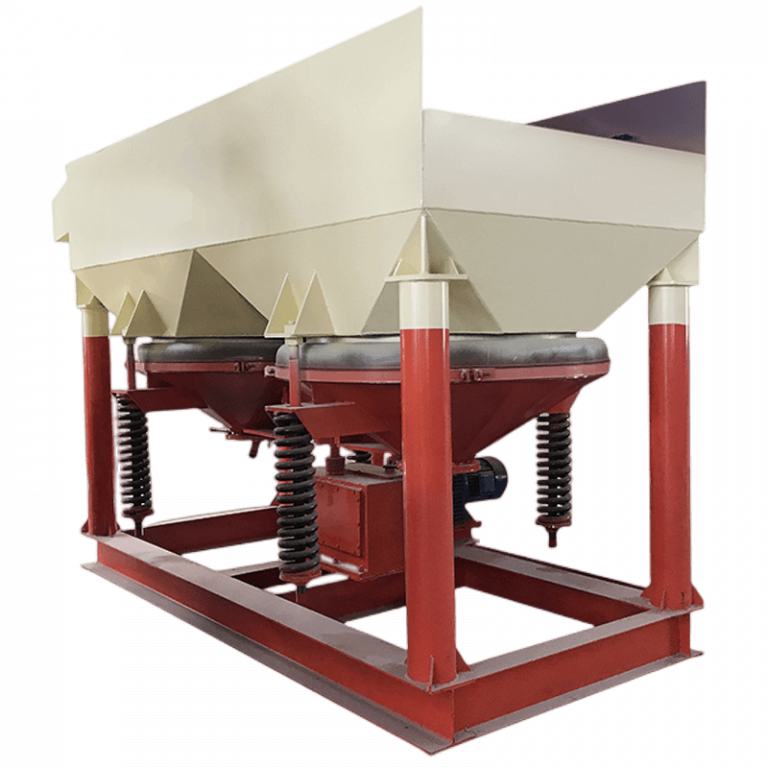

Suspended Vibration Cone Concentrating Machine

Capacity: 8-15 Ton Per Day

Application: Mainly used for the gravity separation of fine-grained minerals such as gold, lithium, tantalum, tungsten, tin, copper, gold, silver, nickel, cobalt, molybdenum, lithium, zirconium, tantalum niobium, lead zinc, titanium, platinum, iron, manganese, chrome, etc.; and the recovery of useful minerals in various new and old tailings.

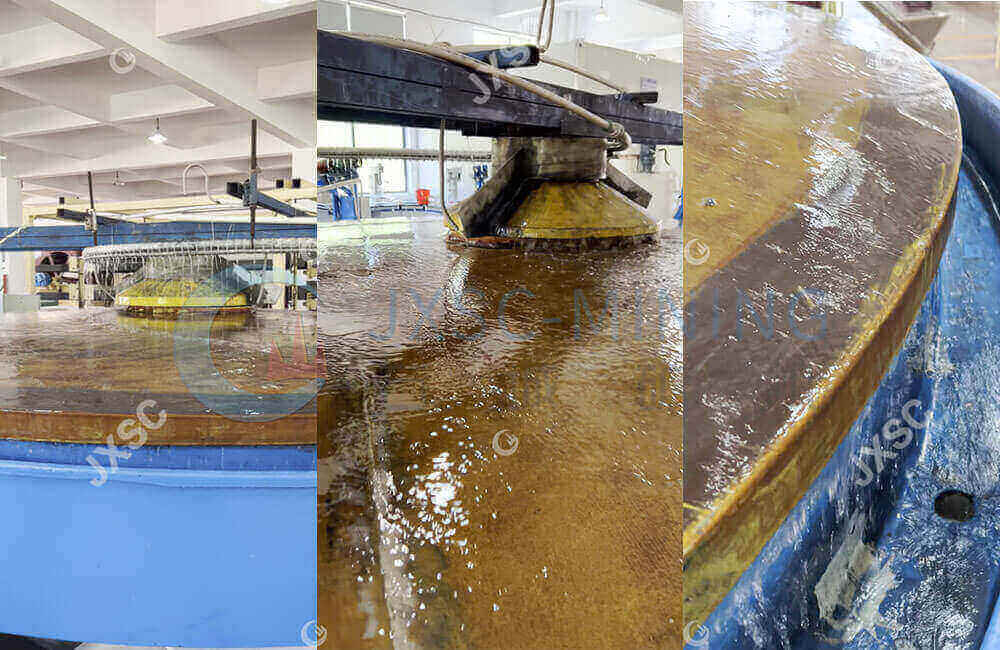

Products display

introduction of Suspended Vibration Cone Concentrating Machine

The suspended vibration cone concentrating machine, suspended vibration cone concentrator, also known as the suspended cone shaking table, suspended vibrating concentrating machine with conical surface. It is a new type of fine particle gravity separation equipment. Usually used in the separation of non-ferrous metals such as tungsten, tin, tantalum niobium, lead, zinc, titanium and ferrous metals such as chrome, iron, manganese, etc., with high enrichment ratio. It can also be used to recover valuable heavy metal minerals from tailings. The sorting disk of the suspended cone shaking table produces a conical spreading flow film. During the flow process, the flow film gradually becomes thinner and the flow rate gradually decreases, which is very beneficial to the recovery of fine-grained minerals.

work principle of Suspended Vibration Cone Concentrating Machine

By combining centrifugal force with vibration, and using a unique combination of gravity and high-frequency vibration, the stratification of materials in the cone chamber is enhanced.

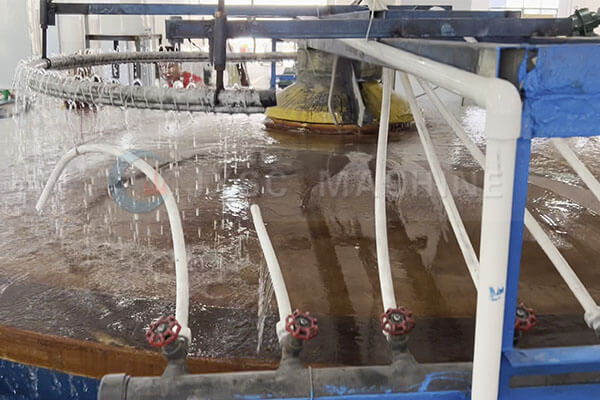

When the evenly stirred slurry enters the roughing area of the sorting surface from the ore feeder after being replenished with water through the slurry replenishment pipe, the slurry flow spreads out in a fan shape and flows around. During its flow, the flow film gradually changes from thick to thin, and the flow rate gradually decreases. Under the shear repulsion generated by its own gravity and cyclonic vibration, the ore particle group is moderately loosened and stratified on the sorting surface, and the sorting surface rotates. At the same time, under the sorting action of involute washing water and concentrate flushing water, minerals of different densities are brought into the tailings tank, the intermediate ore tank and the concentrate tank in turn.

why choose JXSC Suspended Vibration Cone Concentrating Machine

Features & advantages of suspended vibration cone concentrator

1. The unique conical design enhances the layering effect by directing the flow of material more efficiently than traditional flat plates.

2. The vibration of the JXSC suspended cone shaking table is small, the infrastructure requirements are not high, and the installation and operation are simple;

3. Can significantly increase the recovery rate of fine metals while minimizing the waste of high-value mineral resources;

4. The suspended vibration cone concentrator can be used to separate various fine-grained minerals with different specific gravity and has a wide range of applications.

models & specifications

Feeding Size | 0.010-0.074 mm |

Cone Diameter | 4200mm |

4400mm | |

Feed concentration | 15%—25% |

Capacity | 8-15 ton per day |

Enrichment ratio | 6-30 (times) |

Overall Dimension | L4800 x W4800 x H2300 |

L5000 x W5000 x H2300 | |

Power | 1.5kw |

Weight | 1.6 ton |

1.8 ton |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.