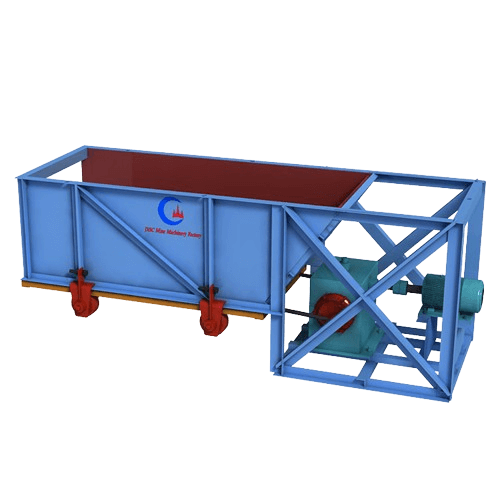

Trough Feeder

Feeding capacity: 5-30 t/h

Application: Trough feeders are widely used for conveying coarse granular or bulk materials, such as pre-crushing feeding in mines, raw material transportation in cement plants, ball mill feeding in beneficiation plants, and metering and conveying in the chemical industry. Examples include gold, copper, iron, marble, limestone, quartz sand, granite, coal, limestone, and construction waste.

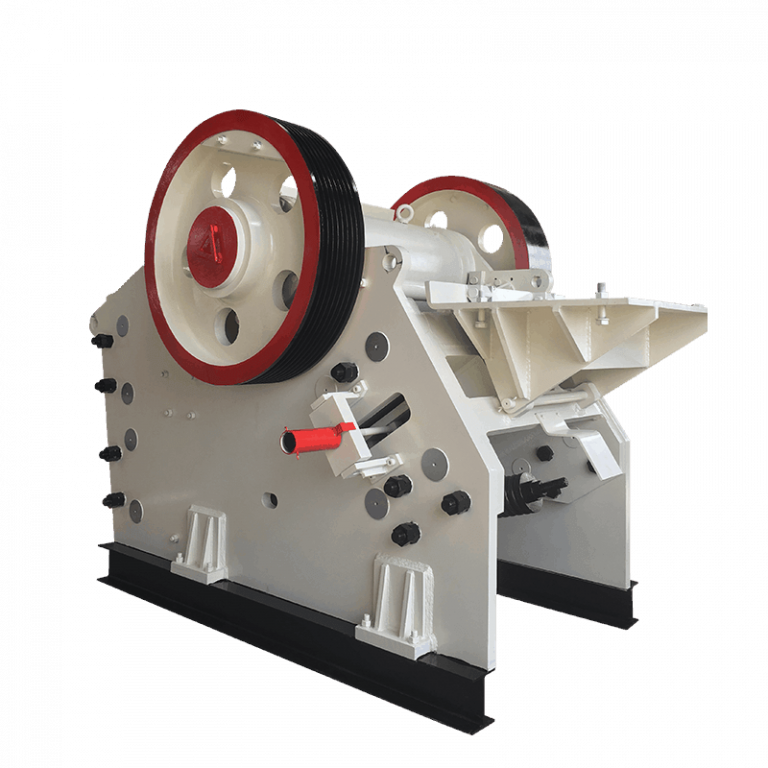

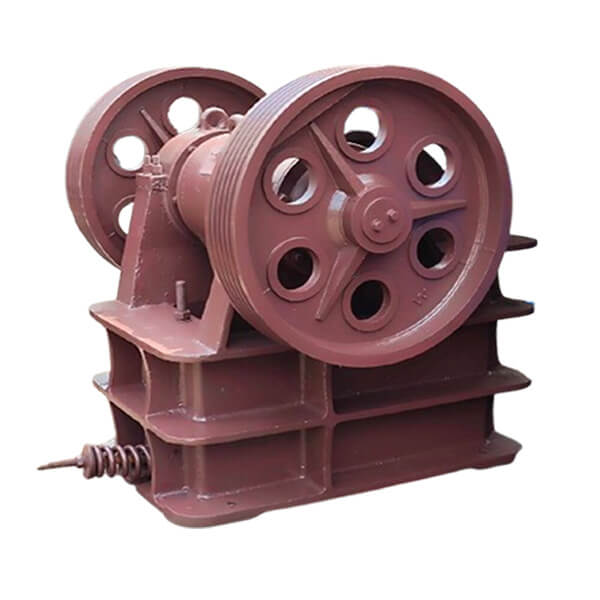

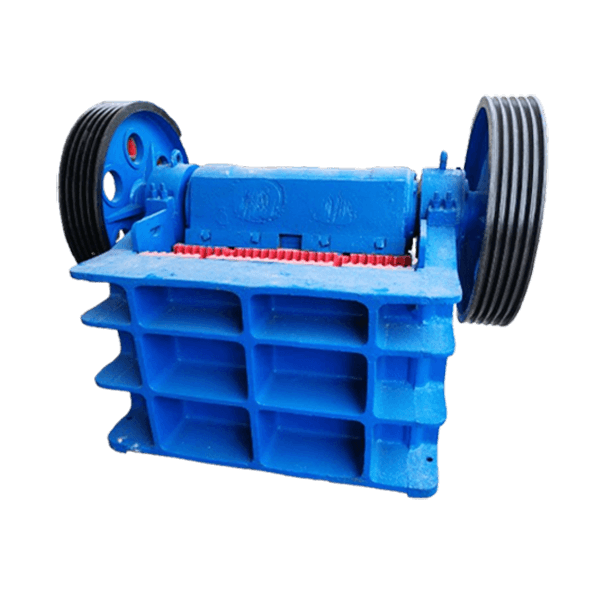

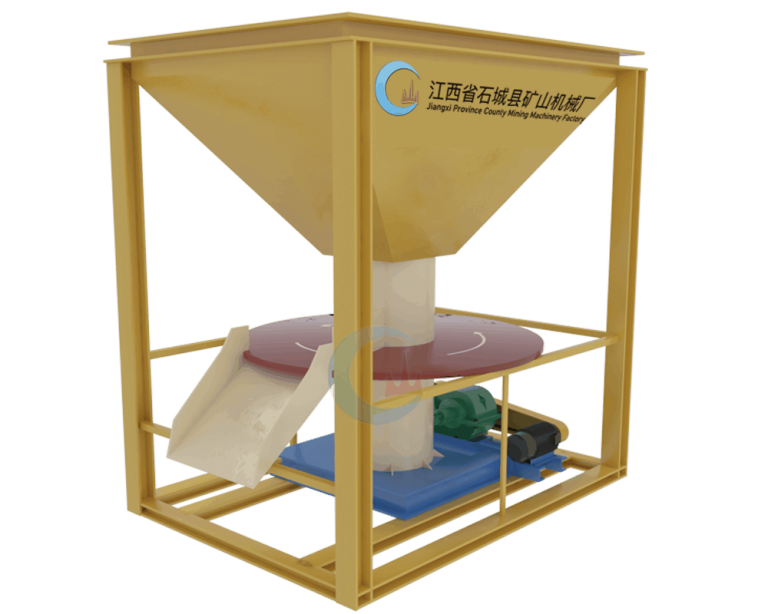

Products display

Introduction of Trough Feeder

A trough feeder, also called a chute feeder, or a reciprocating feeder, is a highly efficient feeding device with a strong structure and strong adaptability. The trough feeder mainly feeds lump and granular materials from the storage silo to various receiving devices, but it is not suitable for conveying concentrate powder and other powdery materials. Its core function is to connect the storage silo with subsequent crushers, ball mills, screeners, and transportation equipment, and to control the material flow by adjusting the stroke and frequency to achieve continuous and stable feeding.

The feeders can be mounted on the ground or hoisted on the silo or discharge port. Commonly used for short-distance material transfer from silos to equipment, simplifying production line layout. The feed rate can be precisely controlled by adjusting the stroke, number of strokes, and gate height, fully adapting to the processing capacity of downstream equipment. It is the key feeding equipment for material transportation and metering in the sand and gravel aggregate production line.

This trough feeder mainly transports various types of block, granular, and special materials through reciprocating or uniform propulsion. It has the advantages of wear resistance, stability, energy saving, and intelligent control. It is an ideal feeding solution for mining, mineral processing, metallurgy, building materials, and other industries.

Principle and structure of trough feeder

working principle

Bulk materials are loaded onto a trough feeder at specific points, often called loading points. It can be done using loaders, excavators, or other material-handling machinery. The trough of a trough feeder is designed to contain and guide the bulk materials being transported. The sloping trough allows gravity to aid the flow of the content, ensuring a stable and consistent supply to the animals throughout the day. The material is then moved along the trough using a continuous belt or chain conveyor system.

Structural characteristics

→ Drive system: Motor, reducer, eccentric/crank-connecting rod mechanism.

→ Feed chute: A key component for loading and conveying materials, typically lined with wear-resistant steel or high-manganese steel.

→ Adjustment setup: Feed rate can be varied by adjusting the gate or variable frequency drive.

Why choose JXSC trough feeder

√ Strong adaptability: The carbon steel or stainless steel trough design is impact- and wear-resistant, capable of long-term operation in high-temperature, dusty environments, making it particularly suitable for heavy industrial applications such as mining and metallurgy.

√ Flexible adjustment: The stroke, stroke rate, and angle are adjustable, and the speed-regulating motor allows real-time adjustment of feed rate to meet high-precision batching requirements.

√ Easy Maintenance: The unit can be mounted on the ground or suspended, lacks complex transmission components, and is easily disassembled for maintenance.

√ Versatile Customization: The unit can be configured with an enclosed dust cover, multiple units in series, or parallel drives to accommodate different material characteristics and site requirements.

√ Environmental protection: The enclosed conveying design reduces dust fugitive emissions.

√ Energy savings: Compared to other feeding equipment, it consumes 15%-20% less energy, achieving a balanced balance between efficiency and cost.

models & specifications

Model | Discharge port size width x height(mm) | Max Feeding Size(mm) | Feeding Capacity | Motor Power | Weight |

600×500 | 600×500 | 200 | 5-10 | 4 | 1045 |

1240×980 | 1240×980 | 350 | 10-30 | 7.5 | 1710 |

models & specifications

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.