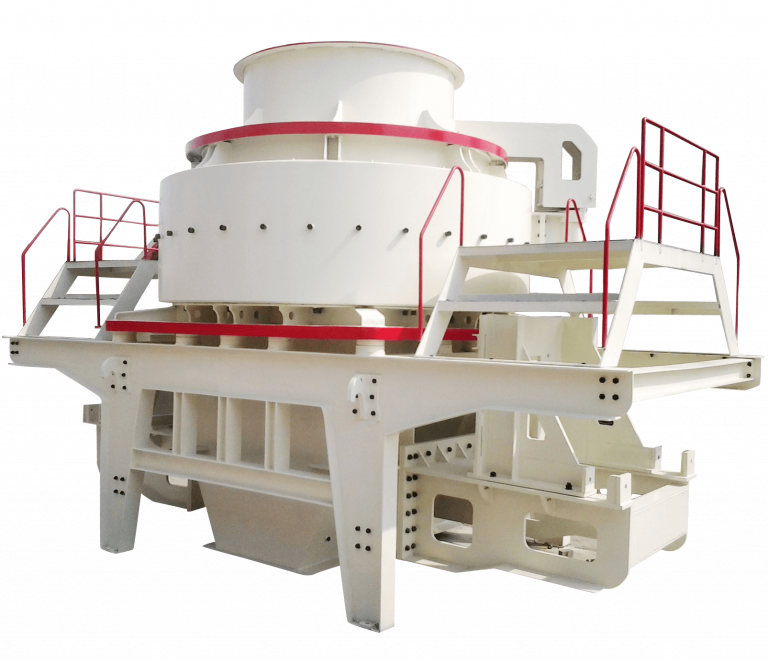

Vertical Shaft Compound Crusher

Capacity: 5-200TPH

Feeding size: <100mm

Application: The vertical shaft compound crusher is widely used in mining, construction, highway construction and other industries; It is suitable for crushing of medium hardness and crushable stones such as limestone, diabase, manganese ore, river pebbles, coal gangue, dolomite, granite, basalt, construction sand, etc.

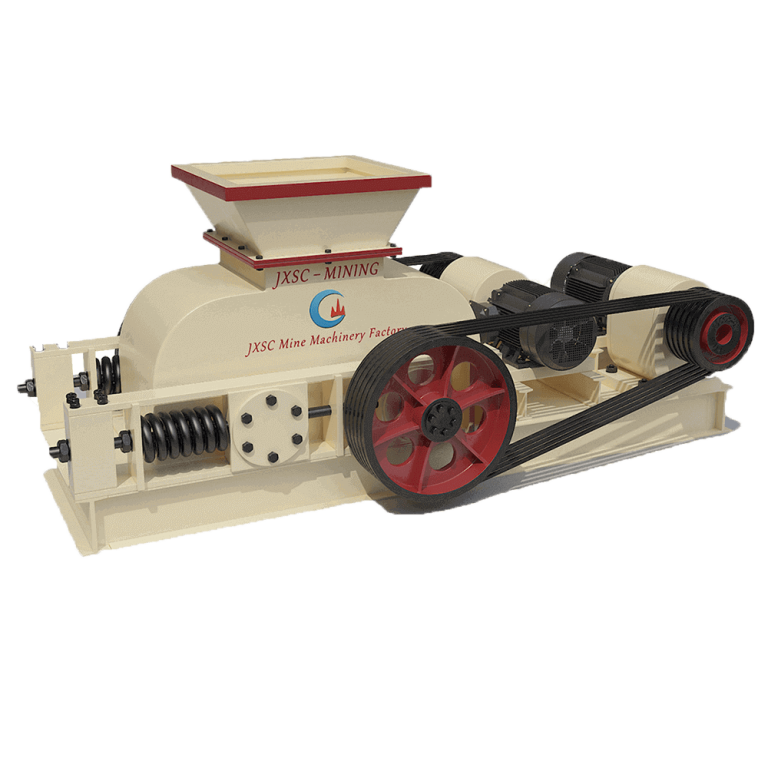

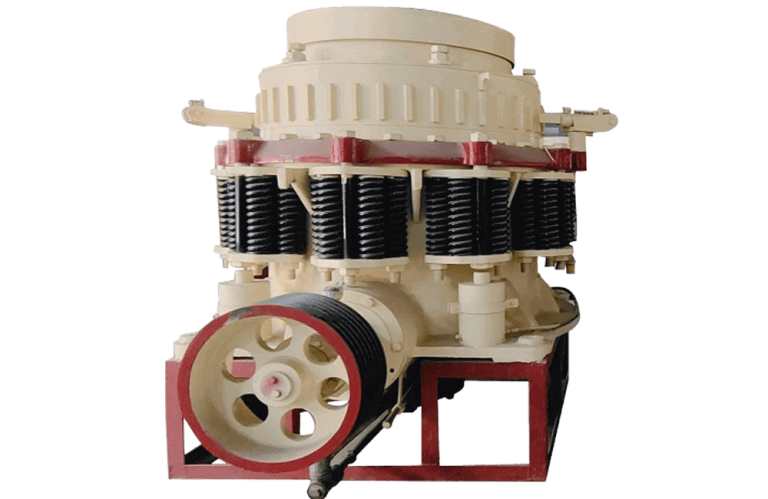

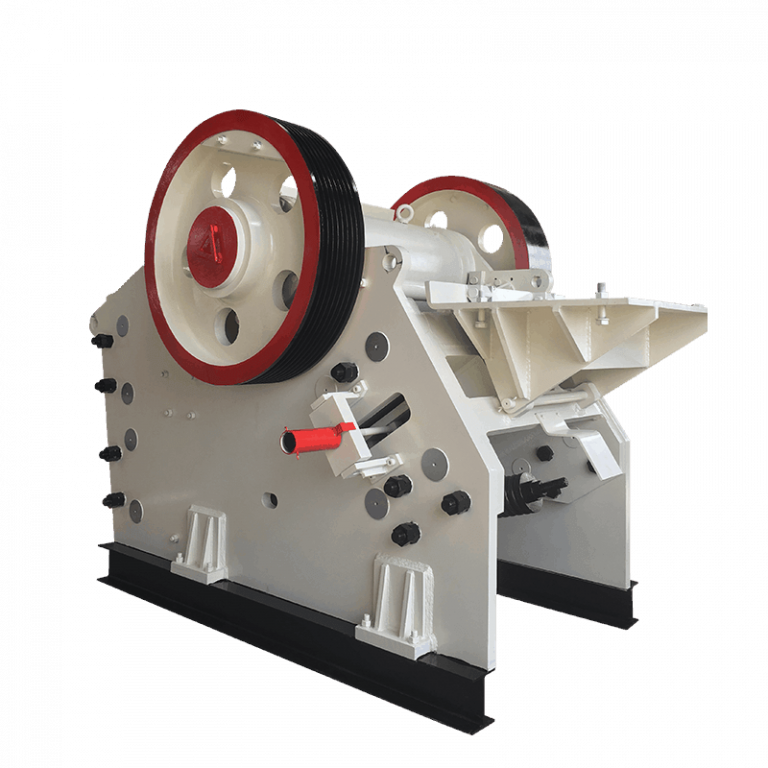

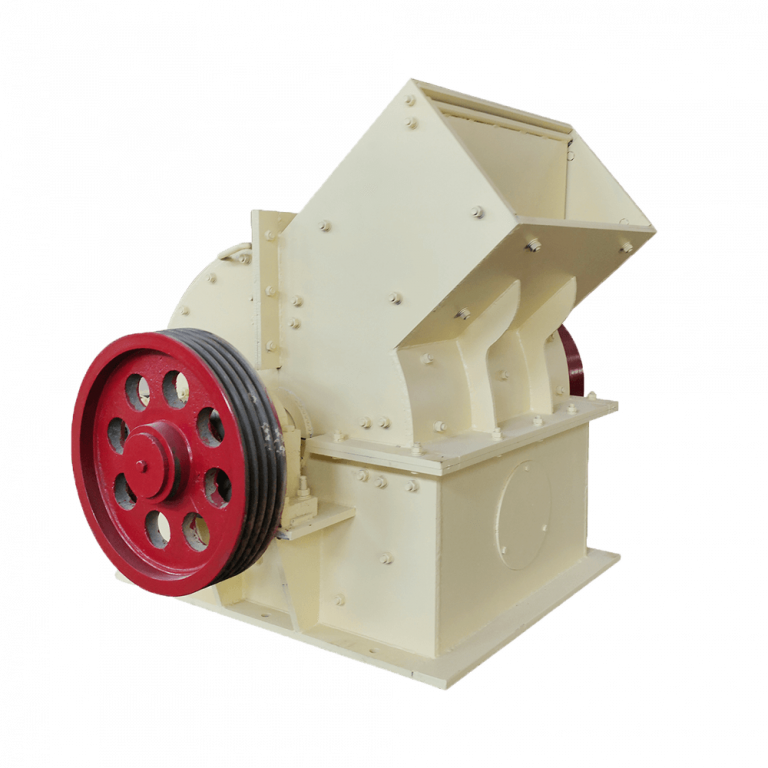

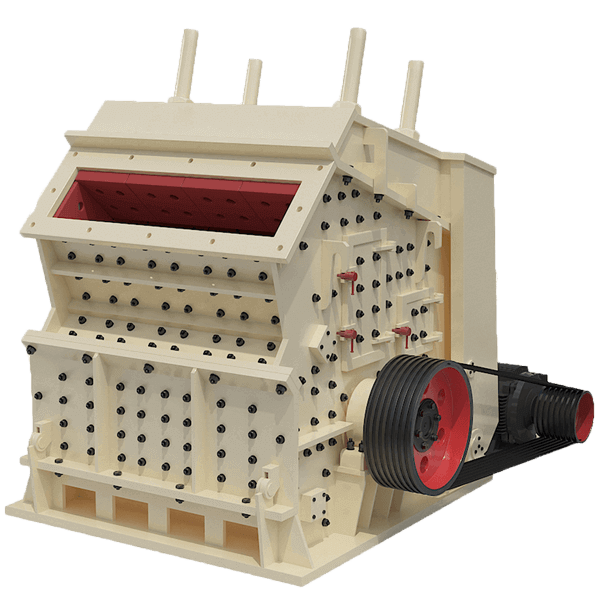

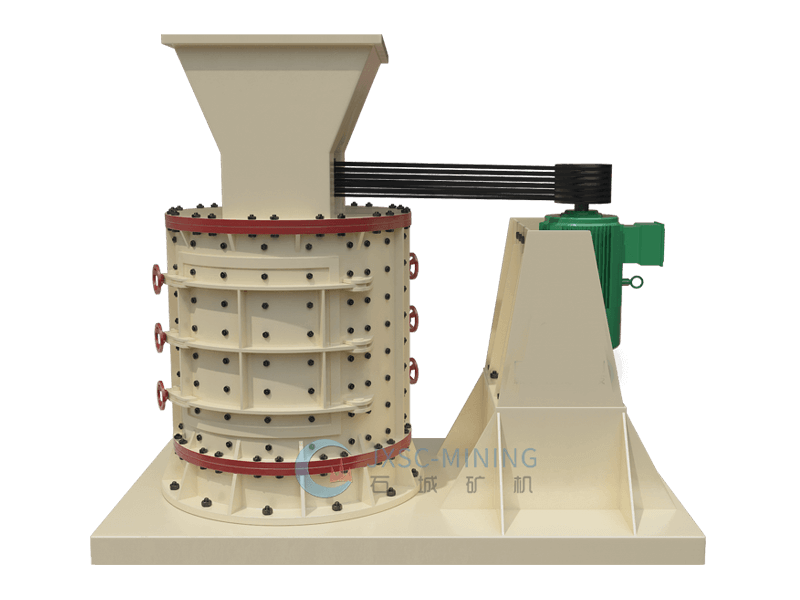

Products display

Introduction of Vertical shaft compound crusher

Vertical shaft compound crusher is also called vertical type crusher, compound sand making machine. It is a fine crushing equipment that combines the advantages of impact crushing and hammer crushing and is optimized with advanced technology. It can achieve the purpose of fine crushing and sand making, and the finished product has better particle shape. With its unique design, the vertical shaft crusher can achieve efficient crushing with minimal energy consumption. The vertical shaft compound crusher has the characteristics of “one machine for multiple crushing functions, high efficiency and energy saving“, making it an ideal crushing equipment for small and medium-sized sand and gravel processing and renewable resource processing.

It is suitable for crushing medium-hardness materials (compressive strength ≤ 350 MPa) such as ores (iron ore, lead-zinc ore), cement raw materials (clinker, limestone), industrial waste (blast furnace slag, coal gangue), construction aggregates (river pebbles, granite, basalt), glass raw materials and construction waste.

The vertical shaft crusher integrates hammering, roller pressing, and grinding, and the output particle size can be controlled by the adjustment device. It can provide sand and gravel aggregates that meet the requirements for infrastructure projects, and the finished product has uniform particle shape (cubic).

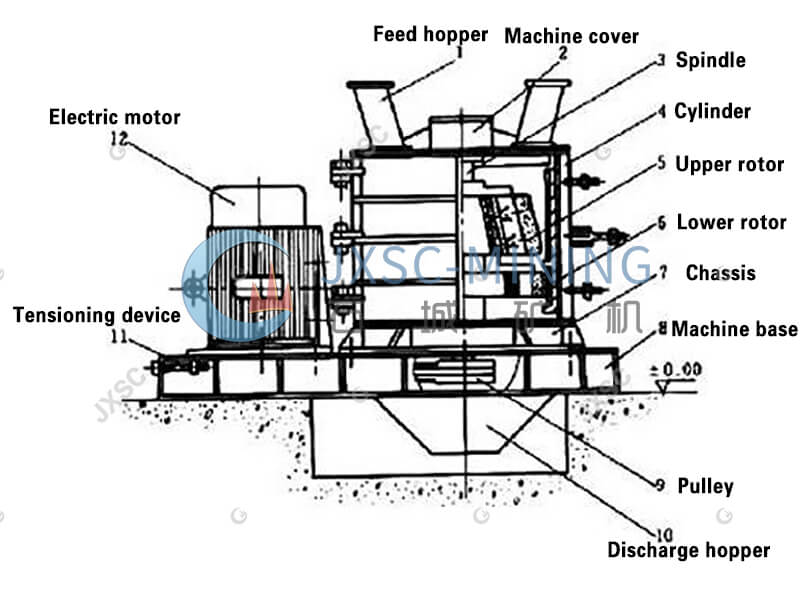

working principle & structure of Impact Crusher

Working principle

The material falls vertically from the upper part of the machine into the high-speed rotating impeller; under the action of high-speed centrifugal force, it is hit by the rotating plate hammer and quickly thrown to the impact plate. After impact, it is rebounded to the hammer plate. Then the materials form eddy currents between the impeller and the casing and hit and rub against each other many times to be crushed. Materials are discharged straight from the top to the bottom, forming a closed circuit for multiple cycles and automatic discharge.

Structural features

- Vertical shaft design

Vertical material drop, small footprint, easy installation and maintenance.

- Multi-stage crushing

Through multi-stage crushing chamber, centrifugal force and impact plate collision, cubic particles are formed.

- Wear-resistant material

Full lining structure reduces material self-wear rate by 50%, and the maintenance cycle is extended by 3 times.

- Multi-function integration

The crusher can realize multiple functions, such as crushing and sand making.

why choose JXSC Vertical shaft compound crusher

features & Advantages

1. There is no screen bar setting, so materials containing mud or moisture are not easily blocked when crushed.

2. The compound crusher adopts high-strength and wear-resistant materials and has a long service life.

3. Closed structure, low noise during operation, no dust pollution, and excellent operating environment.

4. The unique vertical mechanism uses the principle of stone against stone, resulting in little wear and low operating costs.

5. The vertical crusher has a large crushing ratio and large output; the discharge particle size is adjustable, fine and uniform.

6. It can replace the traditional “jaw crusher + impact crusher” secondary crushing and reduce equipment investment, high one-time forming rate.

models & specifications

Model | Rotor diamter(mm) | Speed of mainshaft | Feeding size(mm) | Discharging size(mm) | Capacity(TPH) | Power(Kw) |

800 | 650 | 1350 | 50 | 0-5 | 5-15 | 30 |

1000 | 800 | 970 | 70 | 0-5 | 10-30 | 55 |

1250 | 1000 | 940 | 100 | 0-5 | 20-60 | 75 |

1500 | 1250 | 650 | 100 | 0-5 | 30-80 | 110 |

1750 | 1560 | 600 | 100 | 0-5 | 40-100 | 185-200 |

200 | 1740 | 500 | 100 | 0-5 | 80-200 | 220-250 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.