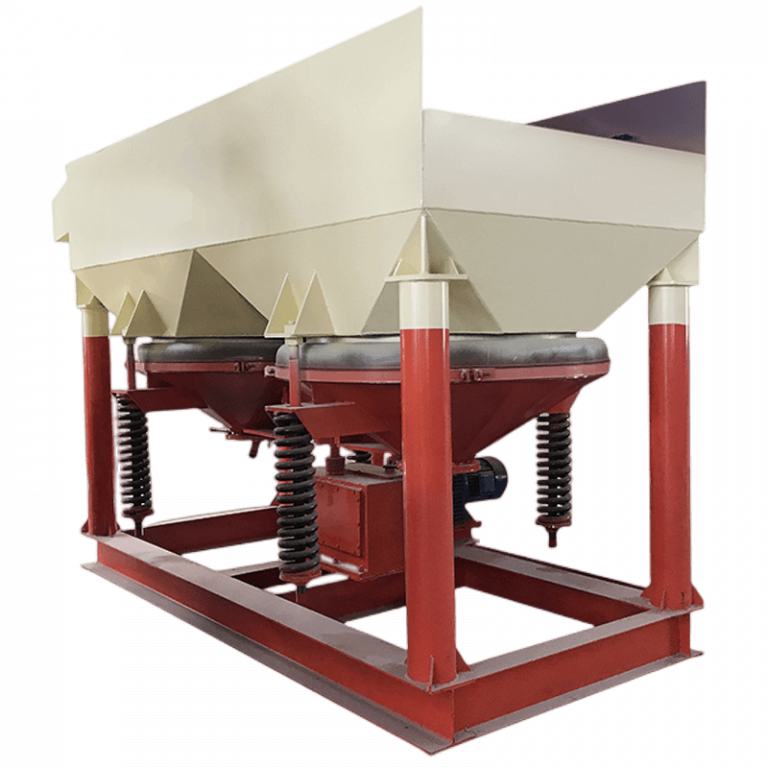

Vibrating Sluice Chute

Capacity: 20-30 m3/h

Application: Vibrating sluice chute is widely used to extract gold from sand after ore washing machine; it can also be installed on the excavation tools of sand dredging ships, sand mining ships and sand pumping ships in the river to extract gold from sand and gravel; it can also be used to recover gold from tailings after iron sand extraction. It is used as a gold panning machine in sand dredging gold panning ships, mobile gold digging machines, and mobile gold panning equipment.

Products display

Introduction of Vibrating Sluice Chute

Vibrating sluice chute, is also called vibrating gold sluice, pulsating sluice box, vibration alluvial/placer gold sluice box. It is a new type of placer/ alluvial gold ore separation equipment based on ordinary fixed sluice box. It is especially effective in recovering capillary gold and thin skin gold. The vibrating sluice chute combines the advantages of gold blanket chute and jig, overcomes the problems of easy compaction, siltation and high water consumption, and is a powerful equipment for panning placer gold. It’s a special gravity separation machine to capture fine gold. Periodic agitation is conducive to stratification and sand discharge, continuous discharge of concentrate, and high enrichment rate.

Working principle Of Vibrating Sluice Chute

During operation, the slurry first enters the feed chute. The width of the feed chute is equal to that of the chute and slightly lower than the chute bed surface, which plays a role in buffering and distributing the slurry to prevent the slurry from directly impacting the bed surface. The slurry is sorted after entering the chute. The bottom plate of the agitation chute is made of natural rubber.

The agitation of the rubber plate is driven by the motor to drive the reducer and the agitation mechanism, forcing the agitation frame to move up and down reciprocatingly. Through this reciprocating motion, the light and heavy minerals in the slurry are separated into layers, and the sedimentary layer is always in a loose state. Heavy minerals and gold particles are deposited at the bottom of the chute, and light minerals are continuously discharged from the tail.

why choose JXSC Vibrating Sluice Chute

features & Advantages

1. With periodic vibration function, mud will not deposit;

2. Low price, simple structural design, low maintenance cost, low water and electricity requirements, environmental protection;

3. Easy to operate, stable operation, good washing effect, high recovery rate;

4. No need to build on a large slope like a fixed chute, the water flow rate is low, and fine gold and flake gold are easy to sink;

5. High degree of automation, it can be used with multiple machines to processing mineral, such as rotary scrubber, trommel screen, centrifugal concentrator, fixed gold sluice box, etc.;

6. Strong adaptability, can be used in muddy areas of mines or various geological structures;

7. Compact design takes up less space and is easy to incorporate into existing gold mining and processing.

models & specifications

Model | JXSC15-40 | JXSC12-33 |

Size (m) | 1.5×4.0 | 1.2×3.3 |

Feed Concentration | 30% | 30% |

Capacity (m3/h) | 30 | 20 |

Water (m3/h) | 60 | 40 |

Maximum feed size(mm) | 20 | 20 |

Vibration frequency (T/M) | 28-30 | 28-30 |

Power (KW) | 3.0 | 2.2 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.