Washing & screening Equipment

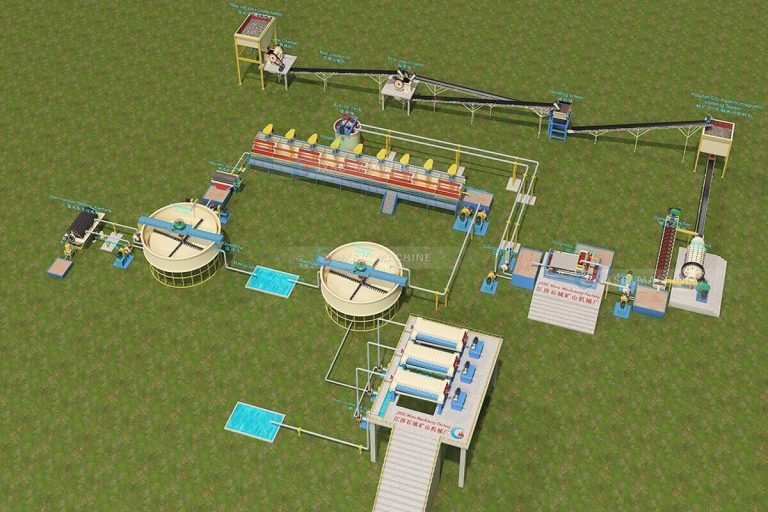

Mining Washing & screening equipment Solutions

JXSC is a leading supplier of specialized mining equipment for washing and screening of minerals, providing efficient, durable, and intelligent ore washing and grading solutions to global mining customers. Mining washing and screening equipment is the core of pre-treatment processes in mineral processing, primarily used to remove impurities and grade ore before crushing and grinding, ensuring the efficiency and concentrate quality of subsequent mineral processing steps (such as flotation and magnetic separation). Our washing and screening equipment includes sand and gravel washing machines (wheeled sand washers, spiral sand washers), rotary scrubbers, trommel screens, vibrating screens, mobile gold washing plants, silica sand attrition scrubbers, fine sand recovery machines, linear vibrating screens, gyratory swing vibration screens, rotary vibtating sieves, etc.

Mining Washing equipment for sale

trommel screen

Capacity: 1-100TPH

Application: Sand and gravel aggregate and ore classifying, screening, washing, processing; gold, diamond ore, silica sand, manganese ore, iron ore, quartz sand and other ore with low mud content.

Trommel scrubber

Capacity: 1-200 TPH

Application: It is widely used to wash rock, ore, sand, gravel and aggregates that contain water-soluble clays; effectively wash and screen ore with high mud content, such gold, copper, manganese, tantalum niobium-tin, etc.

Sand washing machine

Capacity: 15-400 t/h

Types: Wheel or Spiral type

Application: quartz sand, limestone, river pebbles, river sand, calcite, aluminum ore and other natural sand and machine-made sand washing; or widely uesd in sand making plant.

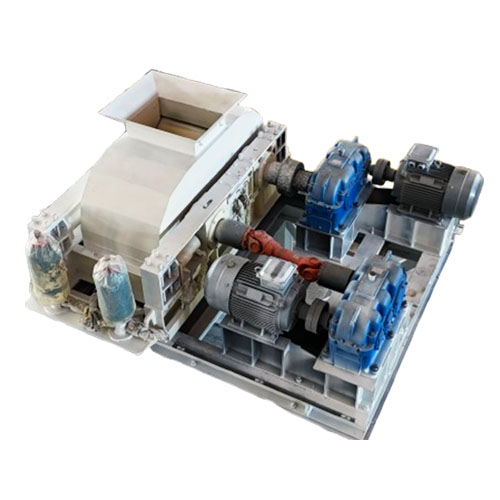

Log washer

Capacity: 1-100TPH

Application: washing of manganese ore, iron ore, phosphate rock, copper ore, barite, hard kaolin, river pebble, granite, basalt, limestone, calcite, quartz stone, diabase and other ores, stones

Attrition Scrubbing Machine

Volume: 1-10 m³

Feeding Size: ≤5mm

Application: scrubbing silica sand(quartz sand), potassium albite feldspar ore, glass sand; ore slime, and removal of impurities on the surface of minerals

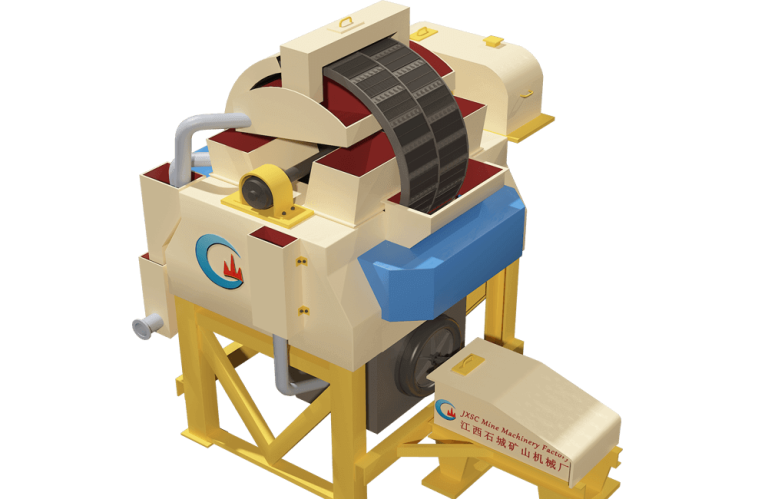

Fine Sand Recycling Machine

Capacity: 30-250TPH

Application: It is mainly used for dewatering and recycling fine sand or fine materials (slurry materials below 0.16mm). It is widely used in sand washing, tailings, silica/quartz sand processing plant, etc.

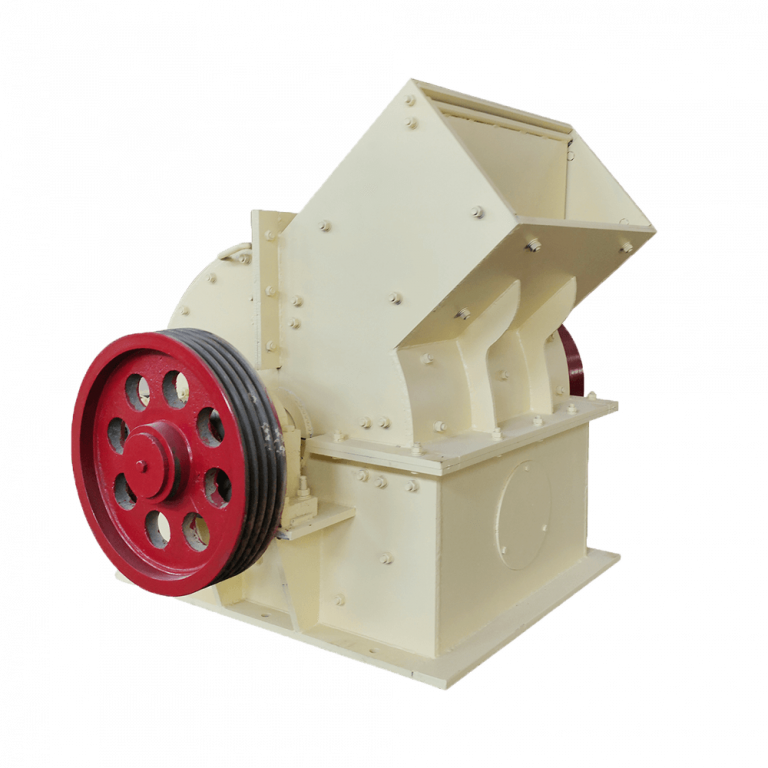

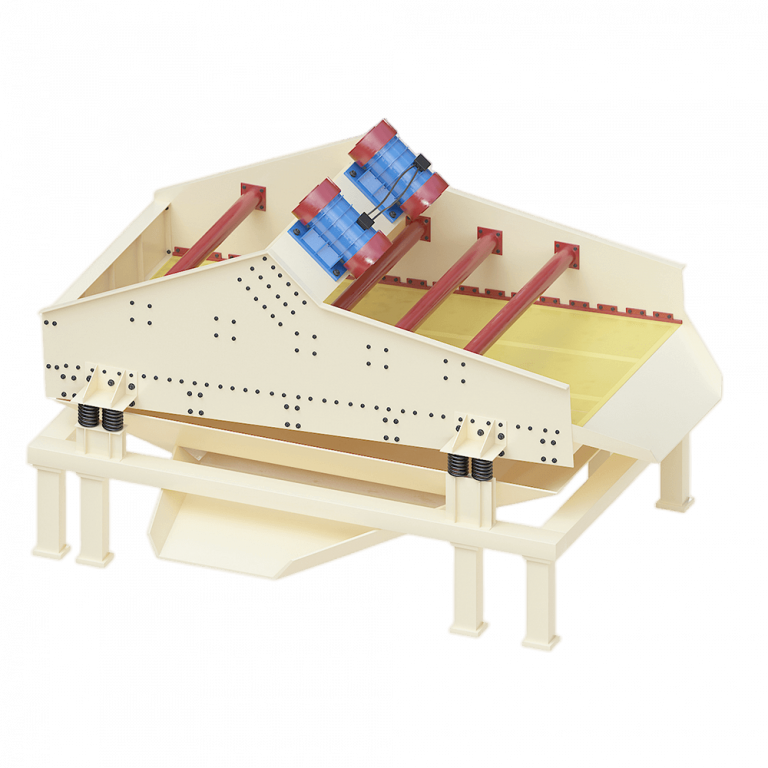

Vibrating Screen

Capacity: 10-250t/h

Layer: 1-4 available

screen mesh: customized

Application: It mainly used to classification of sand and gravel aggregates; the screening of gold, iron ore, copper, manganese, diamond, lithium, chrome, limestone, granite, marble, etc.

Wheel Sand washing machine

Capacity: 15-200 t/h

Application: Wheel sand washing machine is mainly used in mining, mineral processing, construction, road construction, bridge engineering, aggregate, sand and gravel plant; such as limestone, calcite, granite, pebbles, iron ore, quartz sand, construction sand, etc.

Spiral Sand washing machine

Capacity: 20-400 t/h

Application: Spiral sand washing machine is commonly used in quartz sand, copper ore, iron ore, gold mine, pebbles, basalt, dolomite, limestone, river sand, granite, manganese, and other sand, aggregate, or minerals for cleaning, impurity removal and grading.

Mining screening equipment for sale

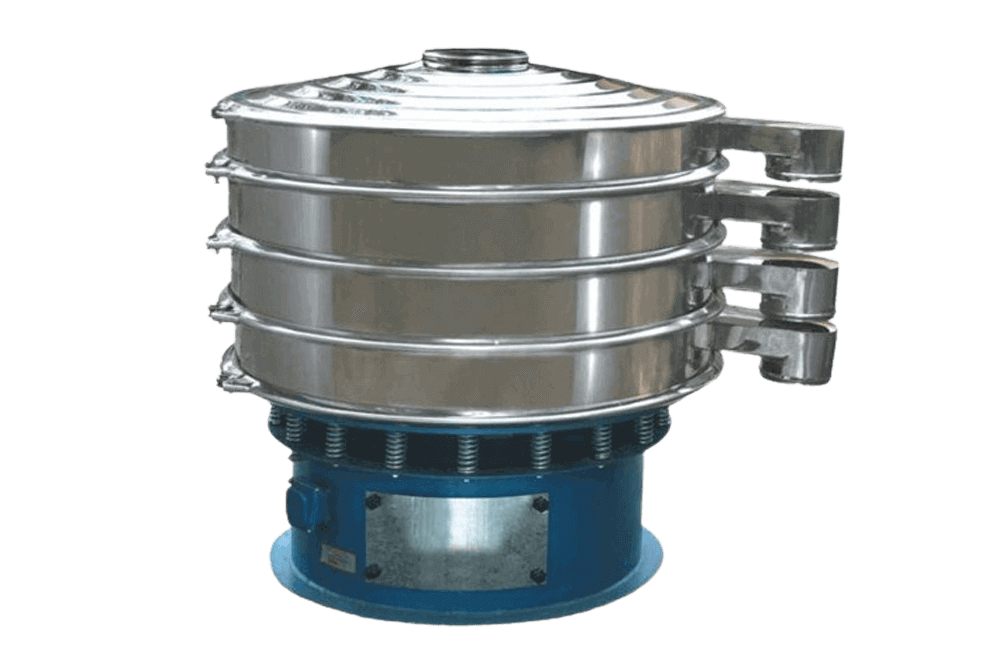

Rotary Vibrating Sieve

Screening size: 0.2281-2.7922 m²

Layer: 1-5

Application: Widely used in food, environmental protection, metallurgy, mining industries; screening, filtration and classification of alumina, silica sand, metal powder, etc.

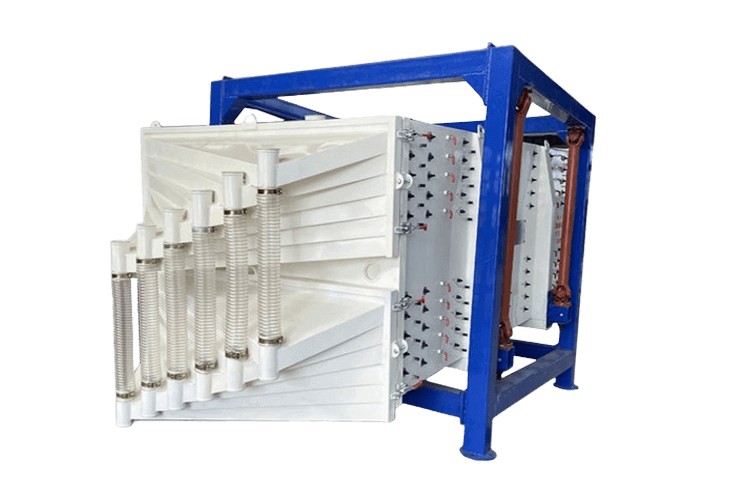

Gyratory Swing Vibration Screen

Layer: 1-5 or customized

Screening area: 3-6.48m²

Application: The gyratory swing vibrating screen is used for screening and classification of silica sand, quartz sand and other granular and mineral powders.

Vibrating Screen

Capacity: 10-250t/h

Layer: 1-4 available

screen mesh: customized

Application: It mainly used to classification of sand and gravel aggregates; the screening of gold, copper, manganese, diamond, lithium, chrome, limestone, etc.

Linear Vibrating Screen

Screen: Multiple discharge holes designed

Applicable materials: Classification and screening of various non-sticky, dry powdery materials such as limestone, quartz, sand, rocks, aggregates, ores, etc.

Why Choose JXSC Washing & screening equipment

- JXSC Washing equipment is primarily used to remove clay, silt, salt, and organic impurities from the ore surface, improving ore purity and beneficiation efficiency. It is suitable for sand and gravel washing, ore washing, and tailings recovery.

- JXSC Screening equipment primarily utilizes the vibration or rotation of the screen surface to separate ore by particle size, enabling precise ore grading and particle size control. It is suitable for pre-screening before crushing, concentrate grading, and tailings dewatering, among other processes.

The mining washers and screeners are widely used in the metal (gold, iron, copper, manganese, chrome, lead-zinc, tin) and non-metallic mineral (silica sand, diamond, beach sand, kaolin) mineral processing plant, and coal mining industries, as well as in the sand and aggregate processing industries. They help customers improve concentrate grade, reduce water usage, increase recovery rates, and meet stringent environmental requirements.

JXSC mining washing and screening equipment works collaboratively to efficiently remove impurities and accurately classify, providing clean, uniform raw materials for subsequent crushing, grinding, and beneficiation. This is also a key component in improving overall mine production efficiency. Contact us to provide customized washing and screening solution tailored to your material characteristics (hardness, viscosity, particle size).

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.