Wet Pan Mill

Capacity: 0.5-3 t/h

Feeding size: <20 mm

Output size: <1 mm

Application: Wet pan mill can be used for wet beneficiation or tailings treatment of metal ores such as gold, silver, iron, lead and zinc; and fine grinding of non-metallic minerals such as kaolin, bentonite, quartz, etc.

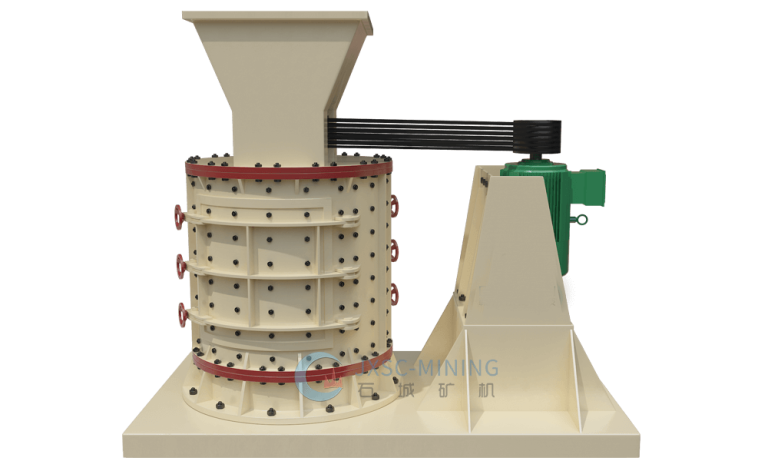

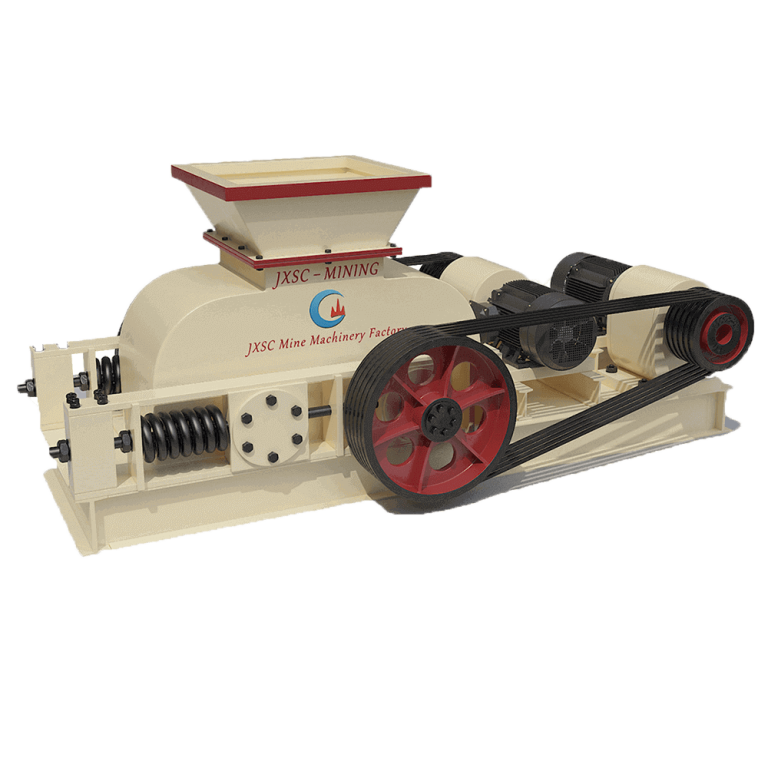

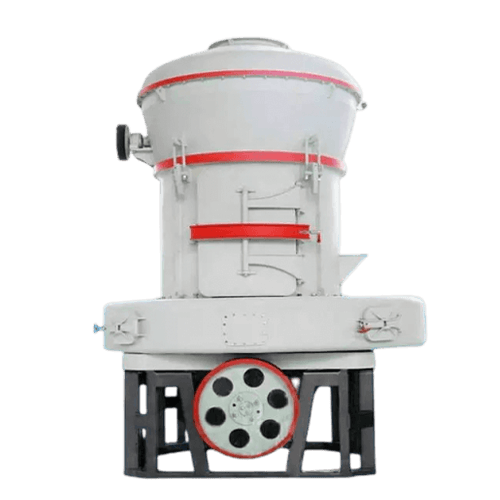

Products display

Introduction of wet pan mill

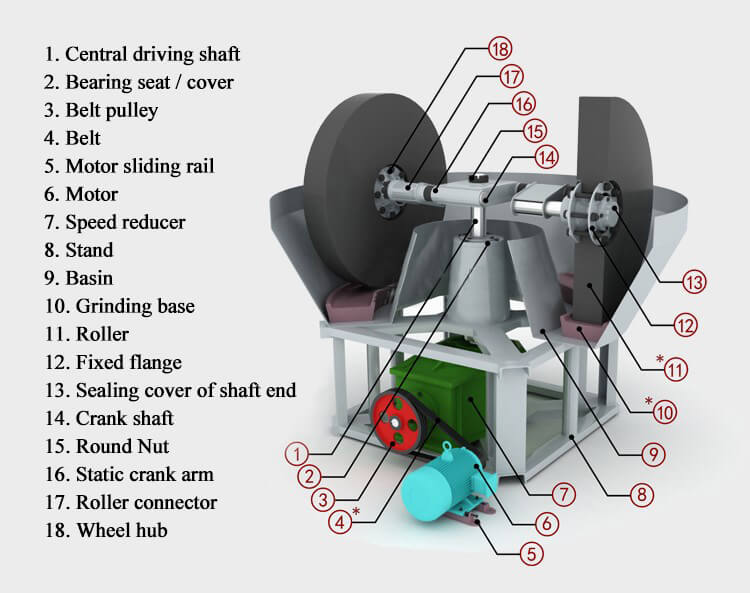

The wet pan mill is the full name of the wet pan grinding mill, gold pan mill, or wheel pan mill. According to the different applications, it is divided into the gold mill, amalgam mill, iron mill, and electric mill. According to the different structure, it is divided into double pan mill, and three pan mill. It is mainly composed of a power unit, a frame, a water basin, a grinding wheel, a grinding plate and other components. It is a wet grinding equipment that combines the functions of crushing, stirring, and mixing. The wet pan mill has the characteristics of strong adaptability, uniform mixing, environmental protection, and energy saving.

The core function of this wet mill is to achieve ultra-fine grinding of materials and slurry homogenization through the synergistic effect of “mechanical force + water power“, so that the mineral particles can be dissociated into monomers (such as separating gold particles from gangue).

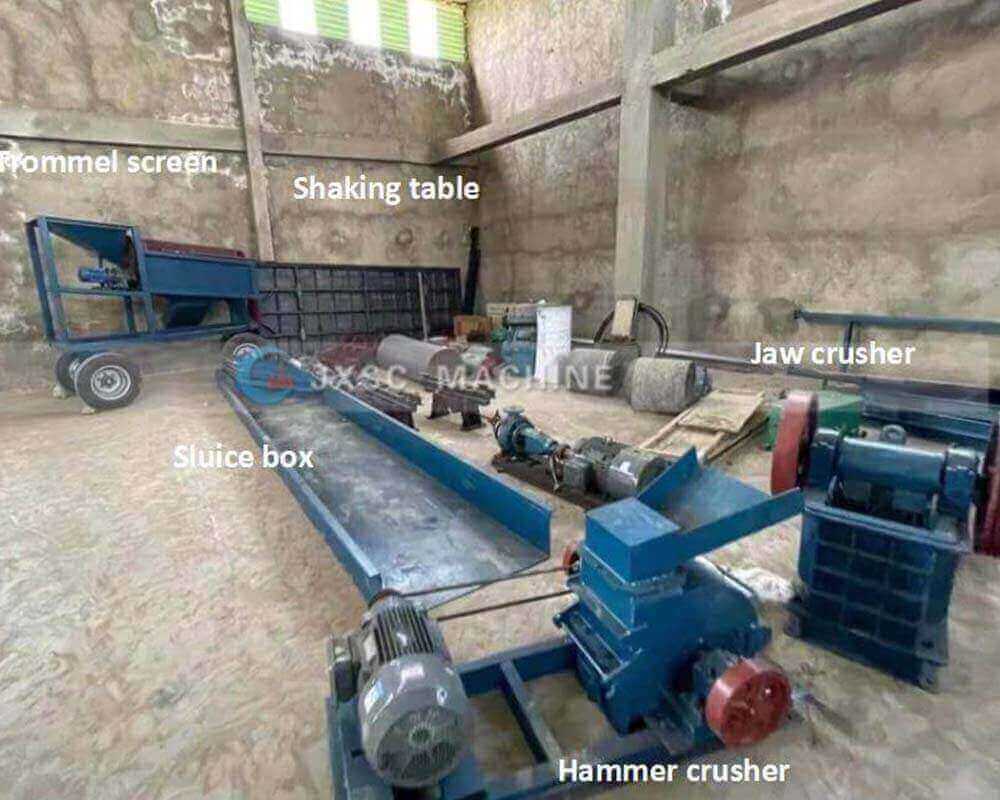

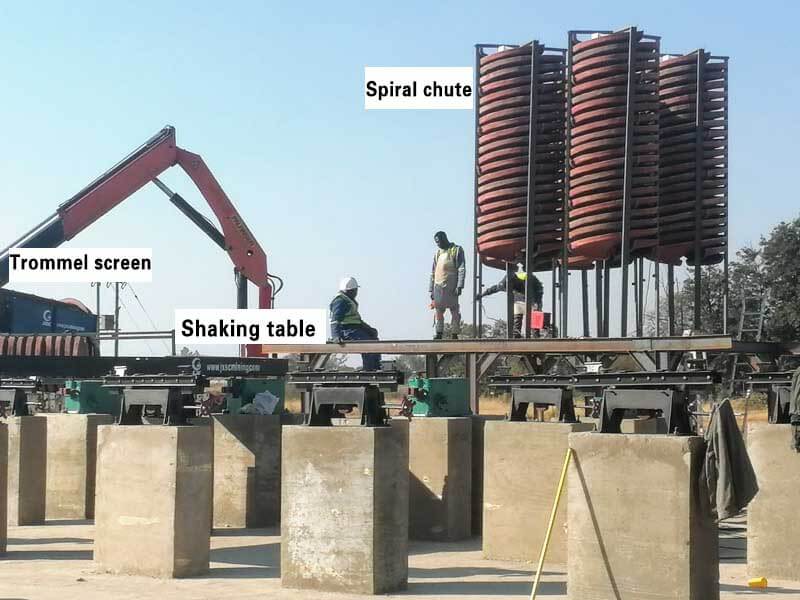

Application: It is used for grinding precious metals, such as gold or silver. The wet pan mill is usually connected with equipment such as crushers, centrifugal concentrators, and shaking tables. Widely used grinding stage for the majority of rock gold processing plants, an alternative to ball mills.

working principle & structure of Wet pan mill

Working principle

The electric motor transmits the power to the reducer. Under the drive of the reducer, the rolling wheel obtains the driving force and rotates counterclockwise along the horizontal direction of the horizontal axis.

When working, the grinding wheel can not only revolve around the large vertical shaft of the wet mill, but also rotate around the central axis of the grinding wheel, while the grinding plate is fixed. The added ore material is subjected to squeezing force from the weight of the wheel in the mill, and the huge friction force generated by the wheel during rotation and rotation of the wheel and the grinding disc is completely crushed after repeated extrusion, kneading and grinding.

Structural features

- Power system: Utilizes a motor + planetary gear reducer combination with adjustable speed. Some models (such as dual-roller models) feature dual motors for independent speed regulation.

- Roller wheels: Made of high-chromium cast iron or wear-resistant rubber, they are individually replaceable, reducing maintenance costs.

- Roller disc: Fixed to the frame, with a wear-resistant lining.

- Water basin and frame: The water basin is U-shaped or circular.

why choose JXSC wet pan mill

features & Advantages

1. A piece of multi-purpose grinding equipment, not only for grinding gold ore but also for gold amalgam.

2. Small investment cost, high output, low production costs, good benefits, well received by users, is the best equipment to replace the ball mill.

3. The products formed by the material milled by this machine have the advantages of high density, good strength, and non-porous ratio.

4. Through repeated rolling, rolling, and crushing of the ore, the moisture content of the ore is balanced, the gas content is low, and the ratio is uniform, so as to improve the forming rate and quality of the gold ore.

5. A good casting process can ensure high rigidity of casting rollers, roller rings, and rollers, and ensure that the castings are wear-resistant, have good toughness, and high density.

models & specifications

Model | Feeding size(mm) | Output size(mm) | Capacity(t/h) | Rotation speed | Power(kw) | Weight(t) |

1100 | <20mm | <1mm | 0.5T/H | 11-19RPM | 5.5KW | 4.8T |

1200 | <20mm | <1mm | 0.5-1T/H | 11-19RPM | 7.5KW | 5.2T |

1400 | <20mm | <1mm | 1-1.5 T/H | 18-21RPM | 15KW | 9.5T |

1500 | <30mm | <1mm | 1.5-2T/H | 18-22 RPM | 22KW | 11T |

1600 | <30mm | <1mm | 2-3 T/H | 18-20 RPM | 30/37KW | 12.5T |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.