ZQ, JZQ, ZQH, ZQSH Series Gear Reducer

- Types: ZQ/JZQ/ZQH/ZQSH are all involute cylindrical gear reducers.

- The working environment is -40℃—+40℃, and can run forward and reverse.

Common features:

-Gear type: involute cylindrical gear, stable transmission.

-Installation form: mostly horizontal, some can be installed vertically.

-Lubrication method: splash lubrication or forced lubrication (depending on the model).

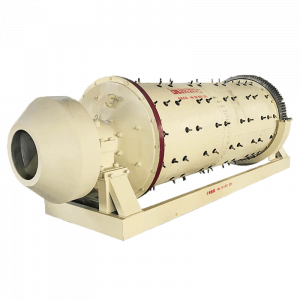

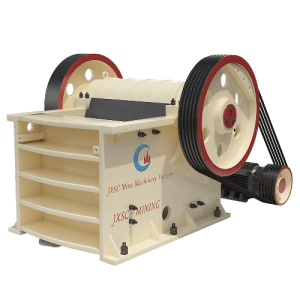

Application: The ZQ series gear reducers are widely used in the transmission systems of equipment in mining, metallurgy, chemical industry, environmental protection and other industries, such as belt conveyors, conveyor lines, ball mills, ore washers, etc., providing reliable power guarantee.

Introduction of ZQ, JZQ, ZQH, ZQSH Series Gear Reducer

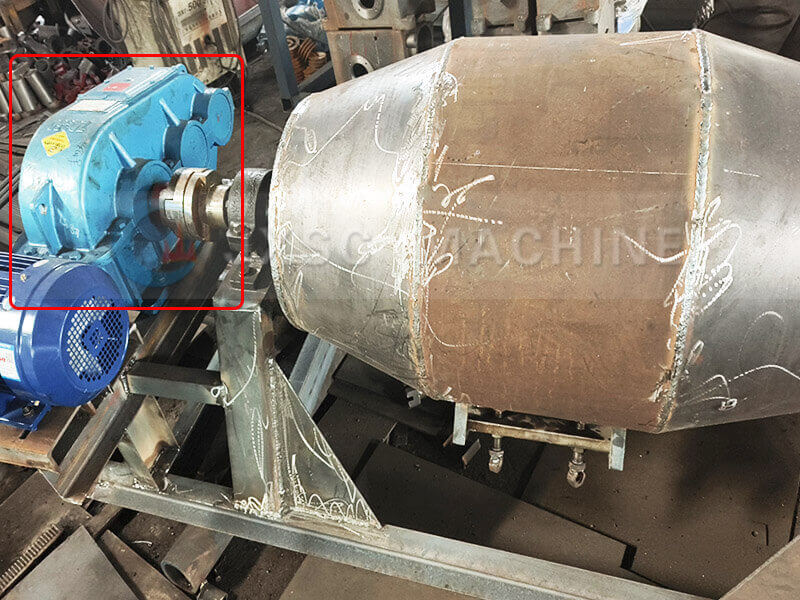

ZQ, JZQ, ZQH, ZQSH series gear reducer is a power transmission device that reduces input speed and increases output torque through gear sets. It is widely used in industrial machinery, metallurgy, mining, lifting, and other fields. Among them, JZQ type is a cylindrical involute gear reducer, ZQH type is an arc cylindrical gear reducer (single arc cylindrical gear is replaced based on ZQ type reducer), and ZQSH type is a two-stage transmission double arc cylindrical gear reducer.

All ZQ series gear reducer models are suitable for crushers, ball mills, sand washers, trommel scrubbers, and other equipment in the mining and beneficiation industry.

Main functions of ZQ Series Gear Reducer

- Match the speed/torque between the motor and the working machine to optimize the power output.

- Adapt to continuous or intermittent working scenarios with medium and low loads, such as conveyor belts, mixers, sand washers, ball mills, etc.

- Provide stable mechanical transmission, reduce impact vibration, and extend equipment life.

Types Of ZQ Series Gear Reducer

1. ZQ gear reducer

It is a standard cylindrical gear reducer with two-stage cylindrical gear transmission. It is a general-purpose basic industrial type suitable for medium load and continuous operation. Its operating temperature is -40C°~+45C°, the input speed is not higher than 1500 rpm, the gear transmission circumferential speed shall not exceed 14 m/s, and it can run in both forward and reverse directions. It is mainly used in belt conveyors, mixing equipment, light industrial machinery, etc.

2. JZQ type gear reducer

It is an economical horizontal involute cylindrical gear reducer with a two-stage transmission structure. It is a simplified version of ZQ (cost reduction design), retaining the core structure of ZQ but reducing the material standard. It is suitable for light industries such as mining, construction, and textiles, such as small and medium-sized general machinery, such as belt conveyors and mixing equipment.. The applicable conditions for the circumferential speed of the reducer gear are not greater than 10m/s; the speed of the high-speed shaft entering the reducer is not greater than 1450. The core advantages are simple structure and low cost, but the load-bearing and durability are weaker than ZQH and ZQSH types.

3. ZQH gear reducer

It is a reinforced involute cylindrical gear reducer, which is an enhanced version of ZQ. It adopts high-hardness gear material and optimized structural design. ZQH reducer is mainly used in medium and heavy load conditions; such as metallurgical rolling mills, mining hoisting equipment, and medium-sized crushing equipment. The total center distance of the reducer is 50cm, the nominal transmission ratio is 40, and the output shaft end is cylindrical. This is a reinforced medium-load gear reducer, positioned between JZQ (basic type) and ZQSH (heavy load type), balancing performance and cost with high-hardness gears and optimized structure. Its load-bearing capacity is better than JZQ, but more economical than ZQSH.

4. ZQSH gear reducer

It is a heavy-duty three-stage cylindrical gear reducer. It uses high-strength alloy steel gears + optimized box structure, and is the model with the strongest load-bearing capacity and the highest reliability in the ZQ series. Built-in forced lubrication system reduces gear wear and has a long service life. ZQSH reducer is an industrial-grade gear reducer designed for extreme working conditions, such as port machinery, heavy metallurgy and other fields, which is irreplaceable; such as cranes, heavy conveying systems, large conveyor lines, port cranes, and deep-sea operations.

why choose Our ZQ, JZQ, ZQH, ZQSH Series Gear Reducer

features & Advantages of ZQ Series Gear Reducer

1. Leading load-bearing capacity and reliability: ZQ series covers graded coverage (JZQ/ZQ/ZQH/ZQSH), meeting the needs of all scenarios from light load to super heavy load.

2. Optimized design, long service life: Gears are precision-processed, the box structure is strengthened, and the wear resistance is improved by more than 30%.

3. Efficient adaptation to extreme working conditions: ZQH/ZQSH has an overload resistance of 150%, and the vibration and noise control are better than similar products.

4. Reliable and durable, smooth operation: We provide a full range of ZQ reducers from economical to super heavy load, with longer life, stronger load-bearing capacity and lower maintenance cost, to help you achieve efficient and stable operation of mining equipment.

models & specifications

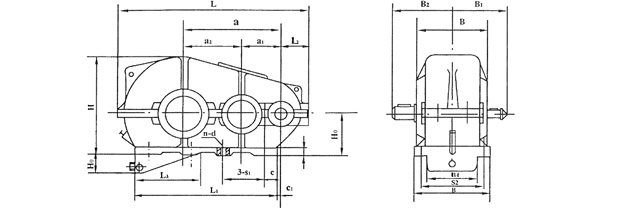

Structure and parameters of ZQ Series Gear Reducer

Model | Center distancea | Center height H | Maximum dimensions | Shaft end size | Maximum quality Kg | |||||||

a | a1 | a₂ | L | B | H | High speed shaftB1 | Low speed shaftB2 | H | ||||

JZQ250 | 250 | 100 | 150 | 160 | 540 | 230 | 313 | 200 | 218 | 230 | ||

JZQ350 | 350 | 150 | 200 | 500 | 730 | 290 | 440 | 260 | 248 | 290 | ||

JZQ400 | 400 | 150 | 250 | 250 | 826 | 310 | 490 | 270 | 303 | 310 | ||

JZQ500 | 500 | 200 | 300 | 300 | 986 | 350 | 587 | 330 | 323 | 350 | ||

JZQ650 | 650 | 250 | 400 | 320 | 1278 | 470 | 695 | 430 | 428 | 470 | ||

JZQ750 | 750 | 300 | 450 | 320 | 1448 | 510 | 740 | 450 | 445 | 510 | ||

JZQ850 | 85 | 350 | 500 | 400 | 1632 | 580 | 875 | 510 | 523 | 585 | ||

JZQ1000 | 1000 | 400 | 600 | 400 | 1896 | 660 | 965 | 550 | 603 | 660 | ||

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.