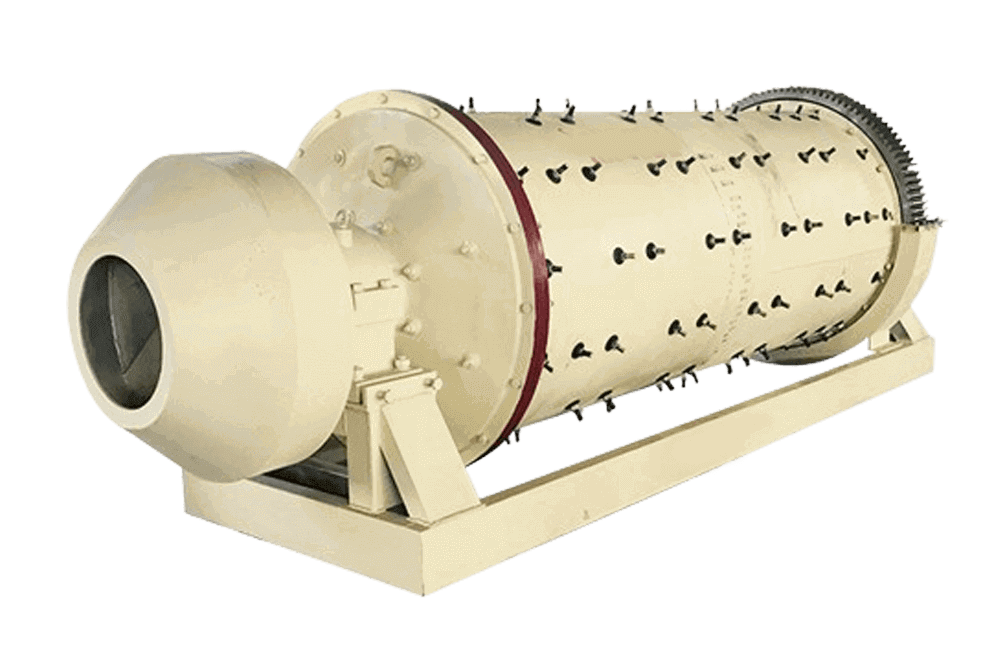

Ball Mill

Capacity: 0.4-150 t/h

Feeding size: ≤20-25 mm

Output size: 0.074-0.6 mm

Application: The ball mill is used for gold, rock, sand, cement, quartz, silica sand, copper, lead-zinc, manganese, lithium, chrome, iron, molybdenum ore, nickel, tin, fluorite, tungsten, iron ore, feldspar, and other metal or non-metallic minerals grinding process.

Products display

Introduction of ball mill

The ball mill is a tumbling mill that uses steel balls as grinding media. Ball mills can be used in wet or dry systems for bulk and continuous milling, and are most widely used in small or large-scale mining & mineral processing plants. It is a mechanical equipment that mainly crushes materials by collision and grinding between steel balls/ceramic balls and materials, and adopts the physical crushing method of rotating cylinder + grinding media. The ball mill has both high adaptability and controllable fineness, and is the core grinding equipment for mineral processing and building materials production. It is especially used for fine grinding and mineral processing pretreatment of metal minerals such as gold, copper, iron, lead-zinc, lithium, chromium, manganese, etc. It is also used for ultrafine powder processing of non-metallic minerals such as quartz, feldspar, limestone, talc, kaolin, etc.

- Dry grinding process: suitable for materials that react with water, such as building stones such as cement and marble. Due to the lack of water resources in some arid areas, dry grinding can also be used in order to save water.

- Wet grinding process: suitable for most materials, various metal ores and non-metal ores. Common ones include grinding gold, copper, iron ore, molybdenum ore, feldspar ore, lithium, chrome, fluorite ore, etc.

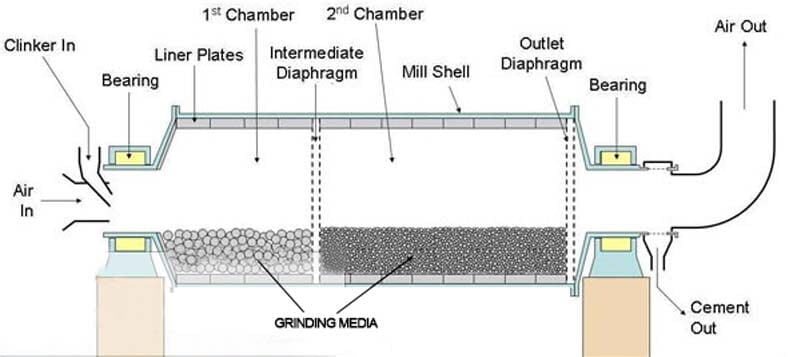

working principle of ball mill

Materials are fed into the barrel of the ball mill through the hollow shaft. A motor drives the barrel of the ball mill to rotate. The materials and media in the barrel spin and move at a certain speed, including gravity, centrifugal force, and friction. When the grinding medium and the cylinder reach a certain height and its weight is greater than the centrifugal force, it will break away from the inner wall of the cylinder and fall or roll down. Since the gravitational potential energy is converted into kinetic energy when falling, the steel ball will eventually collide with the ore at a certain speed, and the impact force will break the ore. The crushed qualified materials are discharged through the ore discharge port.

Types of Ball Mill

1. By discharge method

- Grate type: Forced discharge via a grate plate, suitable for coarse grinding (product particle size 0.2-0.8mm), such as in metal concentrators.

- Overflow type: Material is discharged with the slurry overflow, resulting in finer grinding (0.074-0.4mm), suitable for grinding cement clinker and chemical raw materials.

2. By process type

- Dry ball mill: Equipped with a concentrator, suitable for anhydrous or low-moisture materials (such as cement raw meal).

- Wet ball mill: Used in conjunction with a classifier to prepare ore pulp before flotation of metal ores.

3. By grinding media

- Steel ball mill: Uses steel balls as the medium, offering strong impact crushing capability, suitable for ores and refractories.

- Baseball mill: A combination of steel rods and balls prevents over-crushing, suitable for brittle materials such as coal and limestone.

4. Classification by Application

- Cement ball mills: typically long cylinder or tube mills, featuring a dual-chamber design (coarse grinding chamber + fine grinding chamber). It can process raw materials such as limestone, clay, slag, etc.

- Ore dressing ball mill: select grid type or overflow type according to the properties of gold, copper and other ores, often matched with flotation machine and magnetic separator.

- Laboratory ball mill: batch small ball mill, which controls the particle size of the material by adjusting the grinding time. Such as scientific research, teaching and small batch production.

Dry mills and wet mills are suitable for different material moisture contents; grate mills and overflow mills focus on coarse grinding and fine grinding, respectively. Special mills, such as cement and mineral processing ball mills, are optimized for specific industries. Energy-saving mills and ultrafine mills represent the current technological development. JXSC covers the full-scenario grinding equipment needs from small-scale laboratories to industrial production lines. Contact us to select the appropriate mill based on your specific material characteristics, grinding requirements and production scale to achieve the best grinding effect and economic benefits.

why choose JXSC ball mill

Features & advantages of ball mill

1. The ball mill can efficiently and finely grind various materials with different hardness and abrasion properties, including metallic ores, non-metallic ores, cement clinker, etc.

2. It has a highly automated control system, including automatic start and stop, adjustment of grinding speed and addition of grinding media to improve the convenience of operation;

3. Our grinding equipment has large processing capacity and can meet the high output needs of mining and metallurgical enterprises.

4. JXSC ball mill is designed to be energy-saving and environmentally friendly. It often forms a closed-circuit ring grinding device with a spiral classifier to produce powder with a relatively uniform particle size.

5. Solid and reliable structure: wear-resistant lining and high-strength transmission components are used, with low failure rate and long service life; good sealing, negative pressure operation and reduced dust pollution.

6. Controllable fineness: 1-100μm powder can be obtained by adjusting the grinding time and medium ratio.

7. Continuous operation: 24-hour uninterrupted operation, suitable for large-scale industrial production.

8. Wet and dry method: wet method reduces dust, dry method saves water resources.

models & specifications

Model | Drum size(m) | Rotation speed | Ball load(t) | Feeding size(mm) | Output size(mm) | Capacity(t/h) | Motor power(kw) | Weight(t) |

MQZ0918 | 0.9*1.8 | 38.8 | 1.92 | ≤20 | 0.074-0.6 | 0.4-2.14 | 22 | 5.34 |

MQZ0930 | 0.9*3.0 | 36 | 2.7 | ≤20 | 0.074-0.6 | 1.1-3.5 | 22 | 6.98 |

MQZ1224 | 1.2*2.4 | 31 | 4.8 | ≤20 | 0.074-0.6 | 0.4-6.8 | 37 | 13.43 |

MQZ 1245 | 1.2*4.5 | 31 | 5.2 | ≤20 | 0.074-0.4 | 1.6-12 | 75 | 17.4 |

MQZ 1530 | 1.5*3.0 | 27.5 | 8.1 | ≤25 | 0.074-0.4 | 2.9-16.5 | 80 | 18.6 |

MQZ 1557 | 1.5*5.7 | 29.2 | 15 | ≤25 | 0.074-0.4 | 4.1-25 | 130 | 24.54 |

MQZ 1836 | 1.8*3.6 | 23.9 | 11 | ≤25 | 0.074-0.4 | 8-40 | 155 | 33 |

MQZ2136 | 3.1*3.6 | 23.8 | 27 | ≤25 | 0.074-0.4 | 8-61 | 210 | 46.8 |

MQZ2436 | 2.4*3.6 | 22 | 28 | ≤25 | 0.074-0.4 | 7-95 | 240 | 73 |

MQZ2465 | 2.4*6.5 | 22 | 36 | ≤25 | 0.074-0.4 | 7-110 | 310 | 76 |

MQZ2736 | 2.7*3.6 | 21.9 | 39 | ≤25 | 0.074-0.4 | 13-145 | 400 | 77 |

MQZ2740 | 2.7*4.0 | 21.9 | 43 | ≤25 | 0.074-0.4 | 13-150 | 400 | 91 |

MQZ3060 | 3.0*6.0 | 19 | 70 | ≤25 | 0.074-0.4 | 100-150 | 800 | 155 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.