Mining Thickener

Capacity: 1.3-1140 t/24h

Application: The mining thickener is widely used for the dewatering process of concentrates and tailings in the mineral processing plant. It is specifically designed for the mineral processing industry and tailing processing, such as concentration of gold, copper, lithium, iron ore, lead-zinc, feldspar, antimony ore, and tungsten ore, etc.

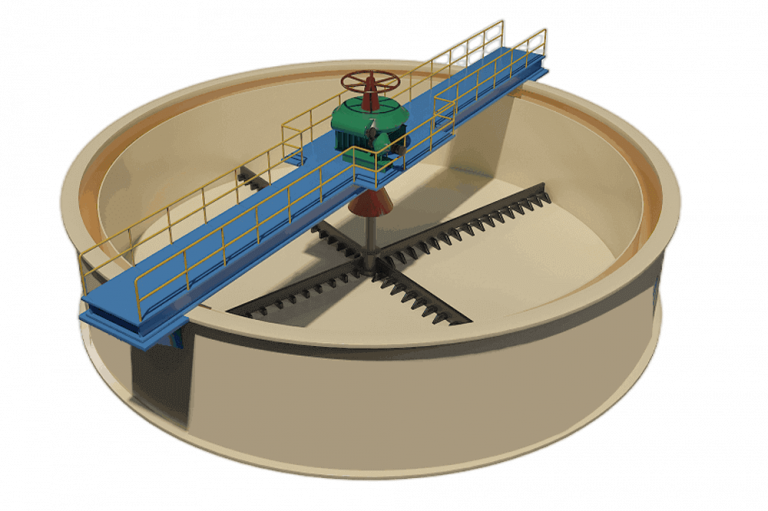

Products display

Introduction of Mining thickener

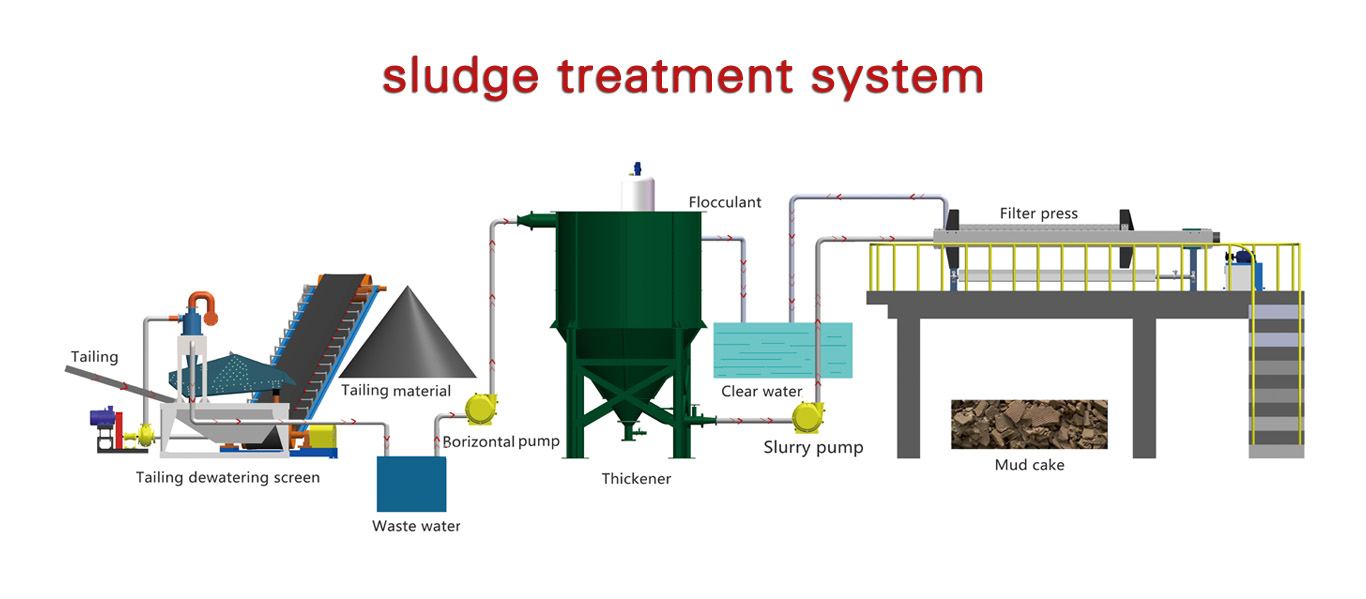

Mining thickeners are recognized as the most cost-effective equipment for water recovery from concentrate and tailings streams. It is a solid-liquid separation equipment based on gravity sedimentation. The concentrated slurry from the thickening process is transported to the tailings dam for disposal, and the recycled water is returned to the processing plant. In thickening (also called sedimentation), the solids in a suspension settle under the influence of gravity in a tank and form a thick pulp. This pulp, and the clear liquid at the top of the tank, can be removed continuously or intermittently.

The thickener is widely used in tailings treatment and return water utilization in mining, mineral processing, metallurgy, chemical industry, and other industries. The core function is to achieve important process goals such as pulp thickening, clarification return water, and tailings dehydration at a lower energy consumption. It is the key concentrating equipment for concentrate dehydration and tailings concentration in mineral dressing plants, and tailings slurry treatment in coal mines. For example, fine particle slurry concentration and overflow clarification after flotation/leaching of iron ore, copper ore, gold ore, lithium, molybdenum, lead and zinc.

working principle of Mining Thickener

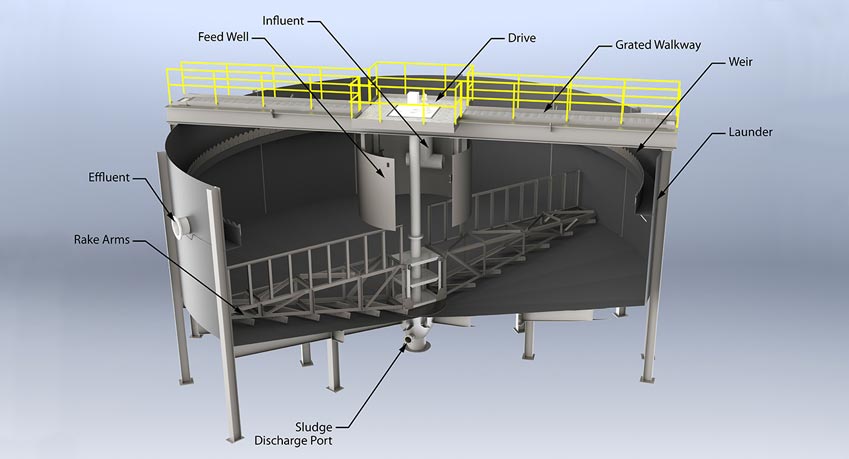

To start with, mineral thickener works on the principle of Gravity sedimentation and the most common construction of a thickener would be iron or steel. The continuous thickener consists of a cylindrical tank. Pulp is fed into the center of the tank via a feed well placed up to 1 m below the surface of the suspension. The clarified liquid overflows a trough, while the solids that settle at the tank’s bottom are withdrawn as a thickened pulp from an outlet at the center. One or more rotating radial arms are there within the tank, from each suspended a series of blades shaped to rake the settled solids toward the central outlet.

mining thickener For Sale

Types Of Mining Thickener

1. Common Thickener

The common thickener can store and buffer the feed. It is the most widely used concentration equipment in mineral processing plants. According to its transmission mode, it can be divided into central transmission type and peripheral transmission type; According to the number of working faces, it can be divided into single-layer, double-layer and multi-layer thickeners. Because of its large diameter, this thickener occupies a large area with low production capacity per unit area. And because it is based on the gravity settlement of particles, the settlement speed is proportional to the square of the diameter of particles, so it has low efficiency in dealing with fine materials. No flocculant required, suitable for concentrating coarse-grained, easy-to-sediment, non-viscous ore pulp, such as iron ore concentrate and coarse-grained copper ore concentrate.

2. Inclined Plate Thickener

A 60° inclined plate group is installed on the top of the ordinary thickener to improve efficiency through the principle of “shallow sedimentation”. These measures accelerate the separation of ore particles, shorten the settling time of materials, strengthen the separation and settling process, improve the concentration efficiency, reduce the capital investment, and increase the production capacity by about three times. However, the inclined plate is easy to block (it needs to be cleaned regularly with a high-pressure water gun), and the maintenance frequency is high. It is often used to process slurries with medium particles and medium settling speed, such as lead-zinc ore slurries.

3. High-Efficiency Thickener

In addition to the inclined plate installed in the thickener, the high-efficiency thickener has a special flocculant adding mechanism. Combined with “deep cone compression” or “inclined plate shallow sedimentation” technology, the efficiency is improved. Its processing capacity per unit area is 10-30 times that of ordinary types, and the solid content of the bottom flow is increased to 50%-60%. It is suitable for processing fine-grained, difficult-to-settle, and easy-to-disperse slurry, such as copper tailings and molybdenum concentrate slurry.

Different thickeners are suitable for various sites, mainly based on material characteristics and the needs of small or large ore dressing plants. If you need a thickener, you can consult us to select the most suitable one according to ore slurry information.

why choose JXSC Mining thickener

1. High-density sedimentation technology is adopted, and the processing capacity per unit area is large.

2. The particle size of the settled solid particles is increased by adding flocculants, thereby accelerating the sedimentation speed.

3. The unique inclined tube/inclined plate group design effectively shortens the sedimentation distance and increases the sedimentation area.

4. It plays the role of flocculation, filtration, and compression, and improves the processing capacity of thick mud residue.

5. Equipped with a complete PLC automatic control system, real-time monitoring of slurry concentration, liquid level, and rake torque.

models & specifications

Model | Thickener Tank | Sedimentation area (m2) | Transmission speed(r/min) | Motor | Capacity(t/d) | ||

Diameter (m) | Depth (m) | Model | Power(kw) | ||||

NZS1 | 1.8 | 1.8 | 2.55 | 0.5 | Y90L-6 | 1.1 | 1.3-5.6 |

NZS2.5 | 2.5 | 1.8 | 4.9 | 0.33 | Y90L-6 | 1.1 | 5-10.8 |

NZS3.6 | 3.6 | 1.8 | 10.2 | 0.38 | Y90L-6 | 1.1 | 5-22.4 |

NZS6 | 6 | 2.956 | 28 | 0.35 | Y90L-4 | 1.5 | 14-60 |

NZS8 | 8 | 3 | 50.2 | 0.27 | Y132S-6 | 3 | 25-120 |

NZS9 | 9 | 3 | 63.5 | 0.25 | Y132S-6 | 3 | 32-150 |

NZS12 | 12 | 3.6 | 113 | 0.19 | Y132S-6 | 3 | 50-250 |

NZS15 | 15 | 3.6 | 176 | 0.1 | Y132M2-6 | 5.5 | 70-350 |

NZS18 | 18 | 3.74 | 255 | 0.2 | Y160M-6 | 7.5 | 100-560 |

NZS20 | 20 | 4.4 | 315 | 0.2 | Y160M2-8 | 7.5 | 200-1440 |

NZS24 | 24 | 4.716 | 452 | 0.1 | Y180L-8 | 11 | 200-1440 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.