fluorite Ore Processing

The main component of fluorite (fluorspar) is CaF2, fluorite ore process mainly includes gravity separation and flotation.

The type of fluorite ore, the embedded particle size, and the ore properties are different. We support customizing the fluorite processing plant and equipment according to the situation and ore properties.

fluorite ore beneficiation process

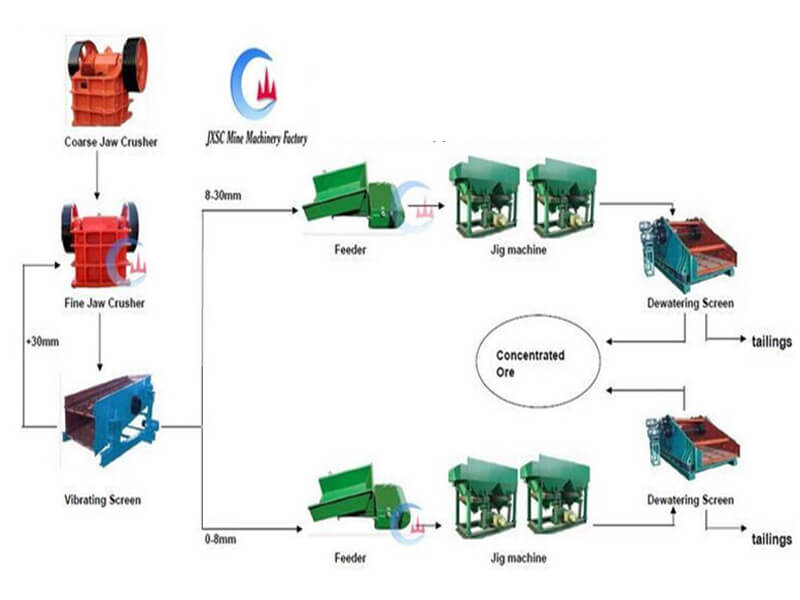

1. Gravity separation method is mainly used to extract coarse-grained massive metallurgical grade fluorite ore; gravity beneficiation of fluorite ore is mainly completed by jig concentrator and the material separation effect is remarkable.

2. Flotation separation is mainly used to produce high-quality fluorite concentrate. The main problem of fluorite flotation is the separation of gangue minerals such as quartz, calcite and granite. According to the different gangue minerals, fluorite ore beneficiation can be divided into the following four types:

- Quartz-fluorite type ore: mainly composed of fluorite (about 80%-90%) and quartz, with only a small amount of calcite, barite and sulfide. The key to the selection is mainly to reduce silicon in concentrates.—(Main process: crushing-grinding-roughing-rough concentrate regrinding-multiple separation);

- Calcite-fluorite type ore: The main minerals are fluorite and calcite (the content is as high as 30%), some of which contain a small amount of quartz, and sometimes quartz-calcite-fluorite type ore can be formed, which is a refractory ore.—(Main process: crushing – grading – jigging – grinding – roughing – multiple flotation);

- Sulfide fluorite type ore: mainly flotation method, adding a small amount of sulfide ore inhibitor (such as cyanide) to suppress residual sulfide to ensure the quality of fluorite concentrate. Prepare high-quality fluorite products while comprehensively recycling valuable metals. —(Main process: crushing – grinding – preferential flotation of sulfide minerals – tailings flotation of fluorite – rough concentrate multiple separations);

- Barite-type fluorite ore: The mineral surface and chemical properties of barite and fluorite in the ore are similar, and the flotation process is often used.

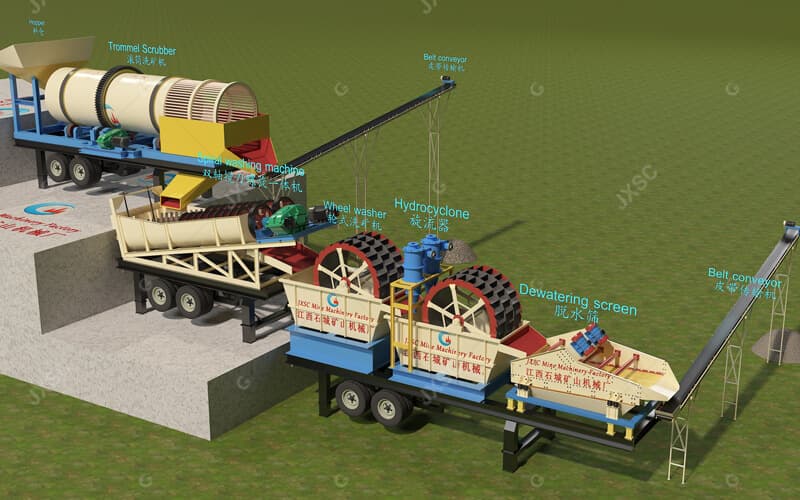

fluorite Ore Processing plant

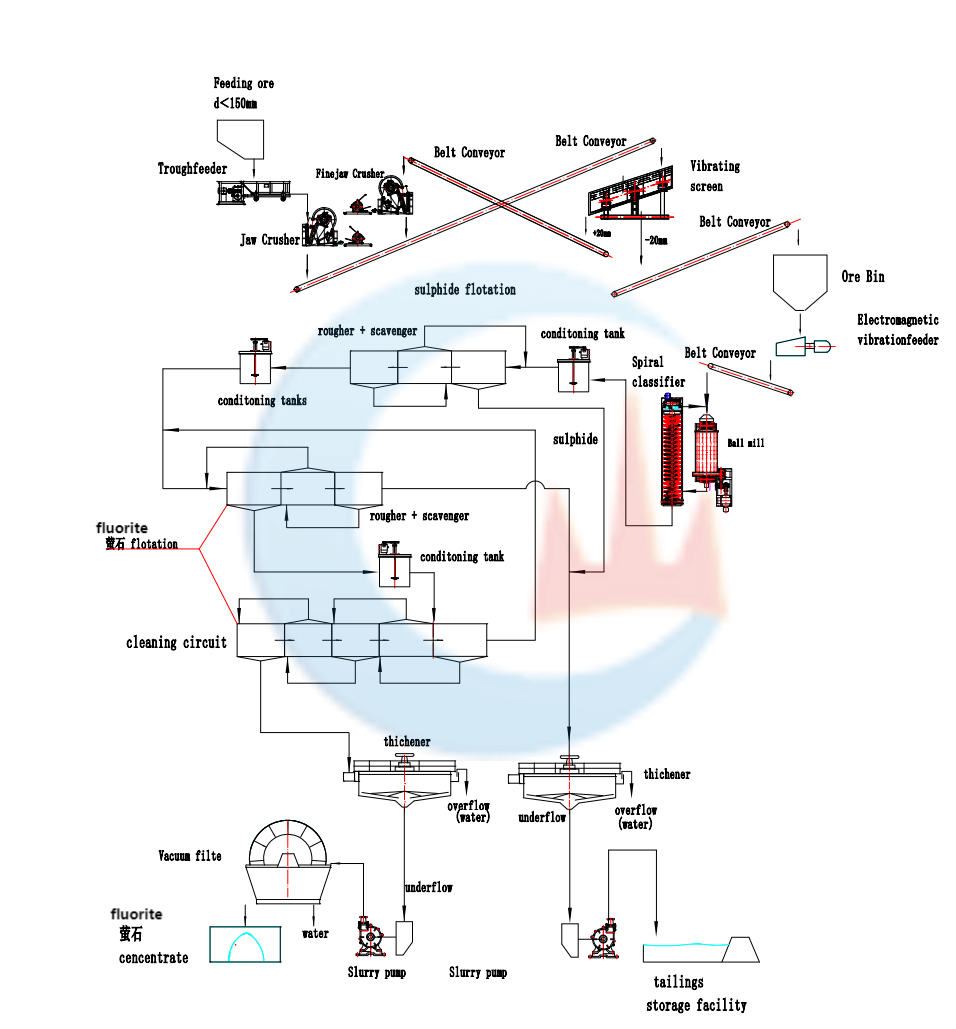

15TPH fluorite flotation plant

This is a complete 15TPH fluorite flotation plant designed for a Pakistani customer. The main equipment and process details are as follows:

Jaw crusher— Vibrating screen— Electromagnetic vibrating feeder— Ball mill— Spiral classifier— Conditioning tank— Flotation machine— Thickener— Slurry pump— Vacuum disk filter

1. Crushing and screening: Due to the different nature of fluorite mines in different regions, some processing plants use a three-stage closed-circuit crushing process, and some processing plants use a three-stage open-circuit crushing process.

2. Grinding: The two-stage grinding process is usually used in the grinding stage of fluorite mines. The ball mill + spiral classifier are combined to form a closed-circuit ring mill, which can be ground to the required particle size.

3. Flotation separation: Fine-grained minerals are separated and enter the mixing tank to be mixed with flotation agents, and then enter the flotation machine for separation.

4. Dewatering: The material enters the thickener to concentrate and recycle clarified water. Then, the concentrate is sent to the vacuum disc filter via a slurry pump, where it is dehydrated into a filter cake.

With this complete fluorite flotation plant and equipment, a high-quality concentrate finished product is obtained. Due to the different properties of ore, JXSC supports customized fluorite flotation process plant equipment, contact us to get more details!

Related equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.