phosphate rock beneficiation

Phosphate rock beneficiation mainly includes crushing, gravity separation, flotation, magnetic separation, etc. It usually combines various processes to achieve maximum resource recovery and utilization.

JXSC supports customized phosphate rock ore processing plants and equipment to mixmize mineral recovery rate.

Phosphate rock beneficiation process

Phosphate rock is an important mineral resource, mainly used in producing fertilizers, pesticides and industrial raw materials. Its beneficiation process is designed to increase the grade (phosphorus content) and recovery of phosphate rock, thereby enabling efficient use of this resource.

- Scrubbing and desilting process is suitable for treating phosphate rock with high degree of weathering, but the grade and recovery rate of phosphorus concentrate are both low;

- Heavy medium beneficiation process of gravity separation, the specific gravity of the main gangue minerals such as calcite, dolomite and quartz in the phosphate rock is similar to that of apatite, and the heavy medium separation method is mainly used. The pollution to the environment is small, and it is good for coarse-grained phosphate rock but not suitable for processing fine-grained phosphate rock.

- Flotation separation is the main method for beneficiation of phosphate ore. It is suitable for processing complex and difficult phosphate ore, and the final concentrate has a high grade and recovery rate.

- Combined gravity-magnetic-floating process is suitable for phosphate rock containing useful associated minerals, and the utilization rate of the ore is high, but the beneficiation process is complex, and complex drug removal treatment is often required.

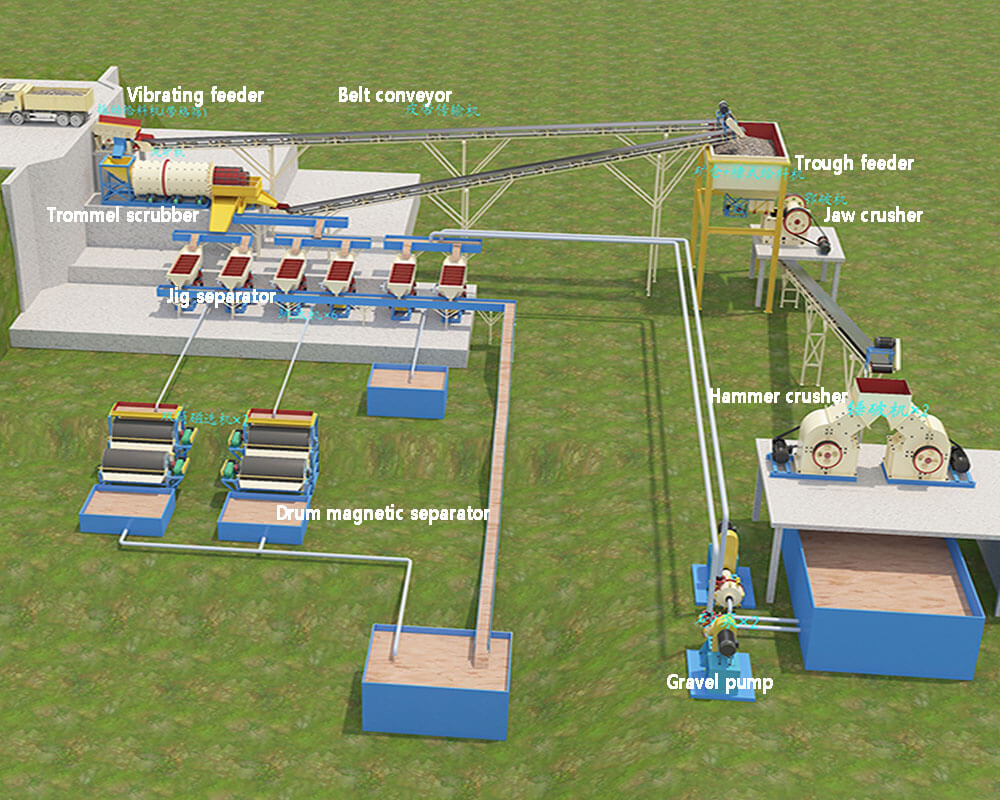

phosphate rock Processing Plant

phosphate rock mineral processing

The phosphate ore processing can be divided into three stages: crushing—separation—concentrate dehydration.

1. Ore crushing process includes crushing, screening, grinding and grading processes. Use crushers and ball mills to reduce ore particle size to dissociate phosphorus minerals from impurity mineral monomers. The degree of grinding depends on the particle size of phosphorus minerals and impurity minerals.

2. Separation process of phosphate rock usually adopts the flotation machine. Usually, phosphate rock contains recyclable iron ore and other associated metals. At this time, magnetic separation and other processes can be added to the flotation process. The magnetic impurity minerals in the phosphate rock are separated and removed by a magnetic separator. The useful associated metals are recovered.

3. Ore dehydration usually includes two processes of concentration and filtration. Thickener is generally used for concentration, and disc filters are used for filtration, so products such as phosphate rock can be easily stored and transported.

The selection of phosphate rock process solutions needs to be determined according to the phosphate concentrate product index requirements and the differences in the properties of the raw ore. Contact us to get more process details and equipment price!

Related equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.