Mineral Processing » Solutions » Stone Crushing plant

Stone Crushing plant

Capacity: 30-1000TPH / Customizable

Feed size: various sizes

Application material: Stone crushing production line for crushing and screening limestone, marble, granite, basalt, cobble, andesite, river stone, dolomite, bluestone, iron ore, and various stone/ ore materials to produce building aggregates with various particle sizes.

Application fields: It’s widely used in sand, rock, aggregate factories, mining, machine-made sand and gravel plant, construction and other industries.

Types of Stone Crushing plant

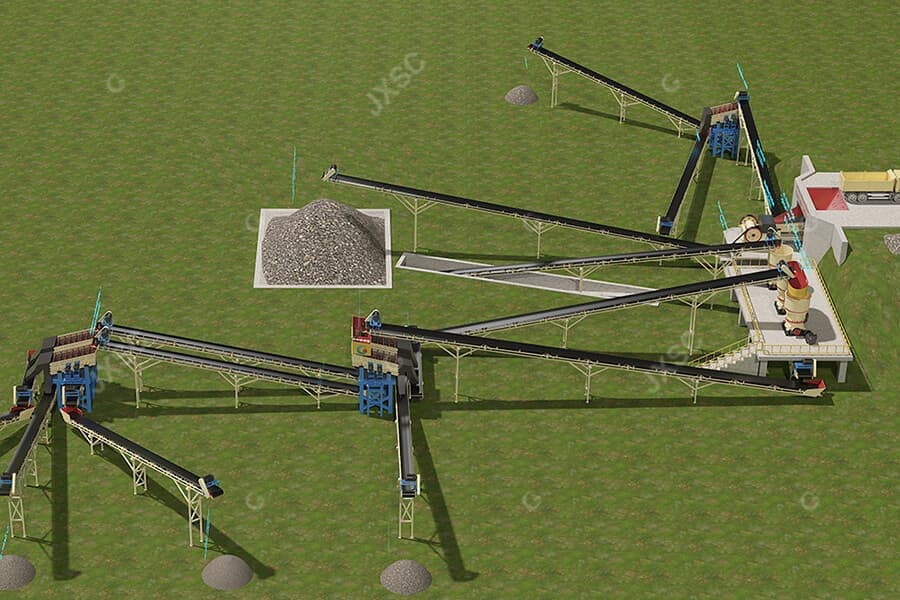

The stone crushing plant is a complete set of equipment that crushes large stones or minerals into sands/ smaller sizes for various purposes. JXSC will carefully equip each stone feeder and crusher based on the hardness and size of the stone, the output needed, and overall production requirements. The feeder, crusher, and vibrating screen can also be integrated into a one-stop, portable stone crushing plant.

We can provide complete crushing line equipment and support customized high-performance fixed and mobile-type stone crushing lines of various capacities.

Features

- Efficient: Achieve efficient and precise crushing of various types of materials and produce high-quality aggregates.

- Wear-resistant: Equipped with rugged and durable components to ensure reliable performance even in harsh conditions.

- Automation: Maximize productivity while reducing operating costs with automated control systems and energy-saving engines.

- Versatility: Whether used for on-site construction projects or for quarries or mines, JXSC customizes the best stone crushing plant for you.

Stone Crushing Plant Process

The stone crushing production line usually includes feeding – crushing – screening processes:

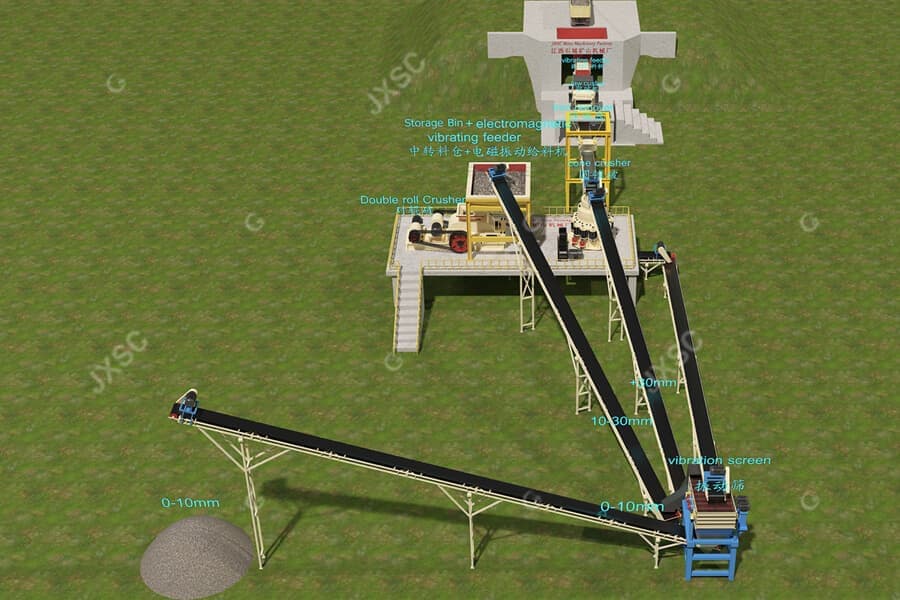

1. Feeding Process

This system ensures a continuous and even flow of stone into the crusher, preventing any bottlenecks or blockages that could hinder the crushing process. It usually consists of a vibrating feeder or hopper box and can be customized to meet specific requirements.

2. Crushing Process

Various stone crushers are commonly used at this stage, including jaw crushers, impact crushers, cone crushers, and hammer crushers. Each type has unique features and benefits, allowing operators to choose the most appropriate type based on their needs.

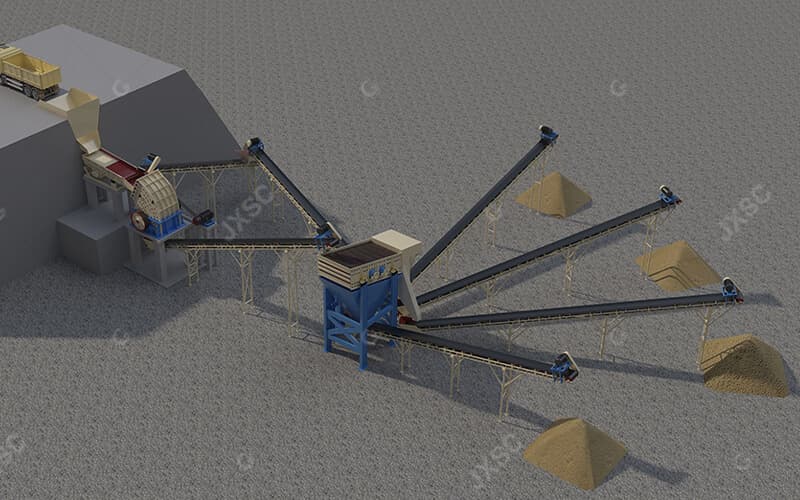

3. Screening Process

The crushed stone enters the crusher for further processing and then is sent to the vibrating screen to separate stones of different sizes. This helps achieve uniformity in the final product and ensures that only the right size sand advances through the production line.

Stone crushing lines are essential in any mining or quarrying operation, ensuring a steady gravel supply for the raw materials required by construction and other industries. We have well-designed and efficient stone crushing lines equipment; contact us to get the factory prices!

Stone Crushing Plant Solutions

Related Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.