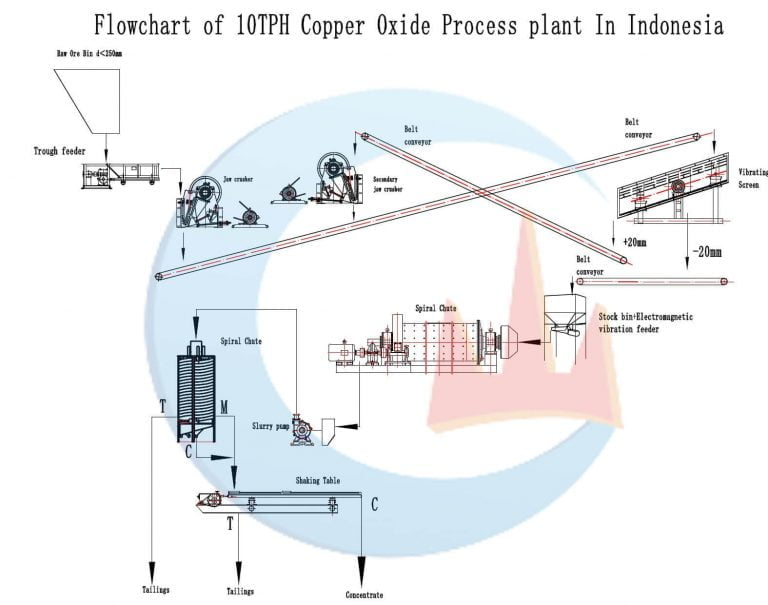

10TPH Copper Oxide Processing Plant in Indonesia

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

minerals

copper oxide, contains clay

capacity

10TPH in Indonesia

feed size

0-250mm

Customer's request

recover copper ore as much as possible

process flow

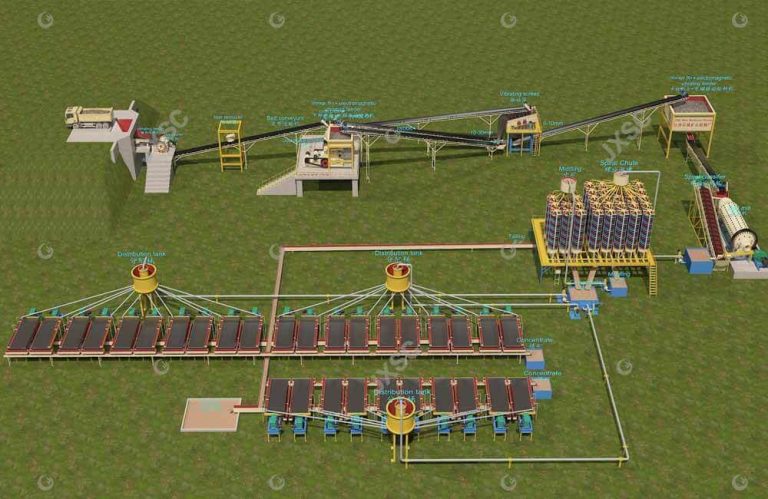

10TPH Copper Oxide Processing Plant

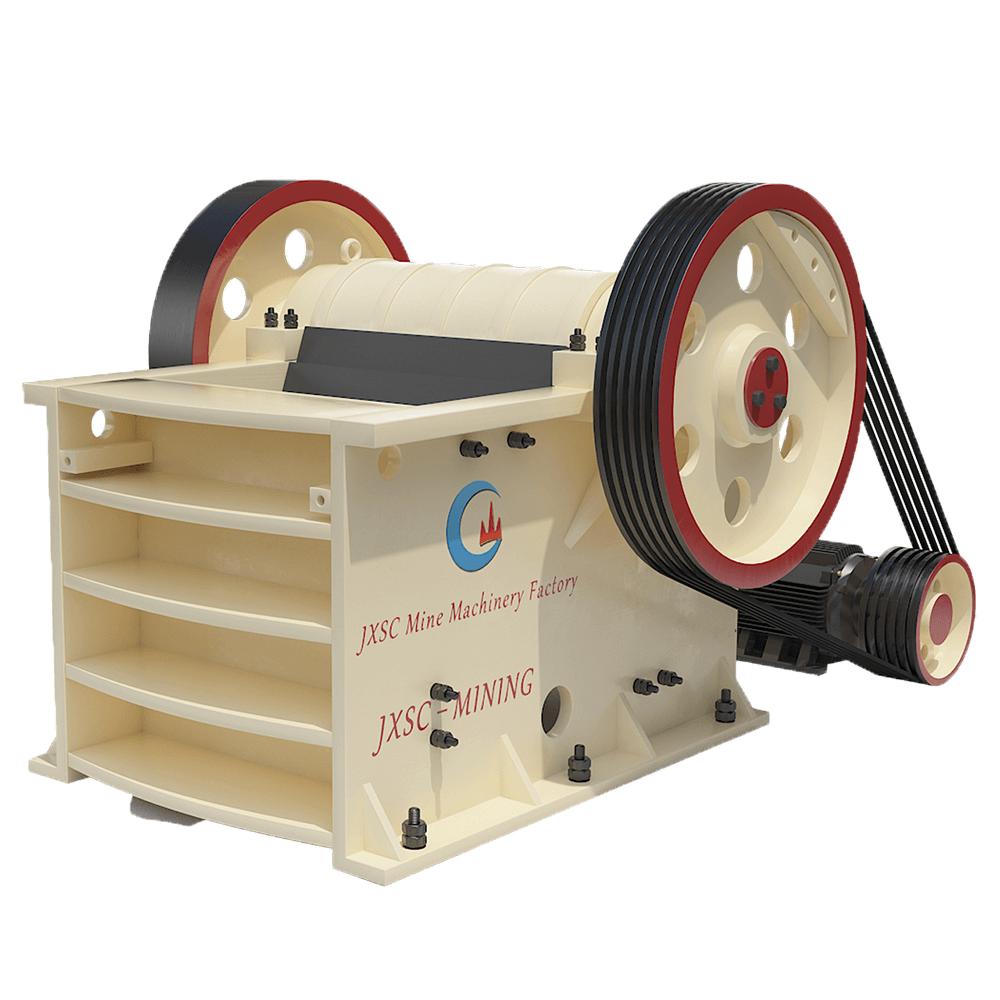

1. Crushing & Screening: jaw crusher, secondary jaw crusher, vibrating screen

The hopper has a screen smaller than 250mm. The 250 mm material is fed into the trough feeder, and then into the first jaw crusher, and the crushed material is conveyed to the vibrating screen by a belt conveyor. The vibrating screen is used to screen out two kinds of materials of different sizes. The materials larger than 20 mm are conveyed to the second jaw crusher by a belt conveyor, and are crushed into 20 mm materials and screened again.

2. Grinding stage: ball mill

Materials smaller than 20 mm are conveyed to the silo by the belt conveyor, and then conveyed to the ball mill for grinding by the electromagnetic feeder

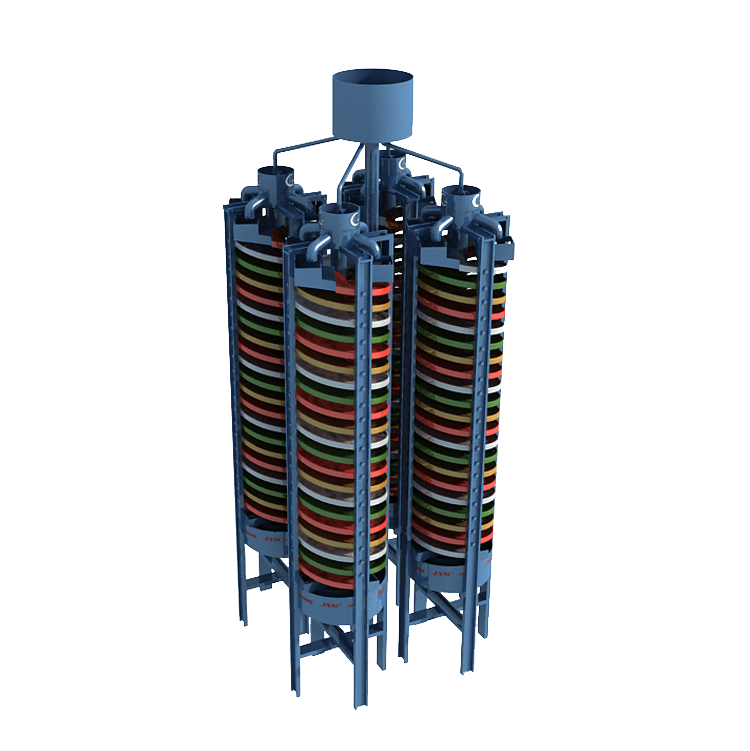

3. Gravity separation: spiral chute, shaking table

The ground material is pumped to the spiral chute with slurry pump, and then enters the shaker for gravity separation to recover higher copper concentrate.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.