24TPD Lithium Flotation Process Plant In Nigeria

We guarantee the high quality machine in the mineral processing industry, established in 39+ years of experience.

Project Info

Materials: Spodumene and lepidolite mixed minerals

Capacity: 24TPD

Feed size: ≤125mm

Location: Nigeria

Process

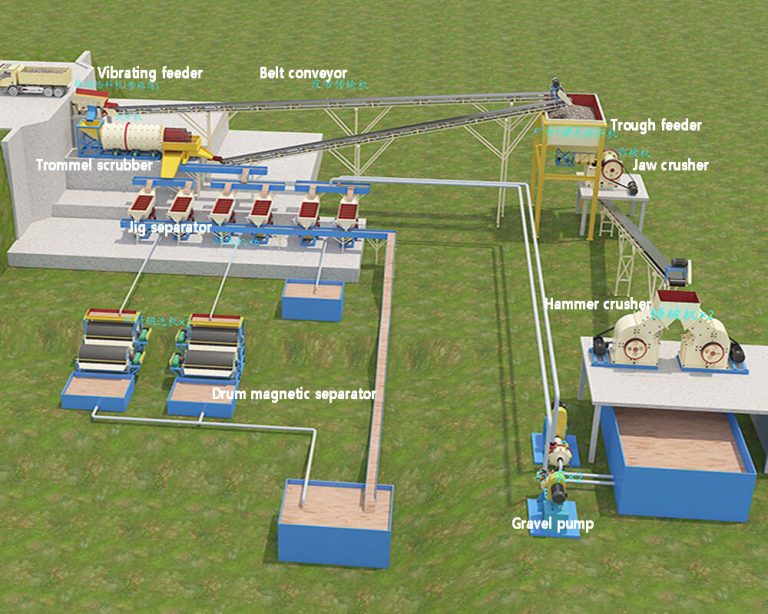

Crushing – Feeding – Grinding & classifying – Flotation

process flow

24TPD Lithium Flotation Process Plant flow

JXSC provides Nigerian customers with a complete set of 24TPD lithium flotation process plant equipment and all accessories. At the same time, we also provide detailed layout design and corresponding infrastructure diagrams. The customer has his own team of engineers to set up the plant, so there is no need for our engineers on-site installation services.

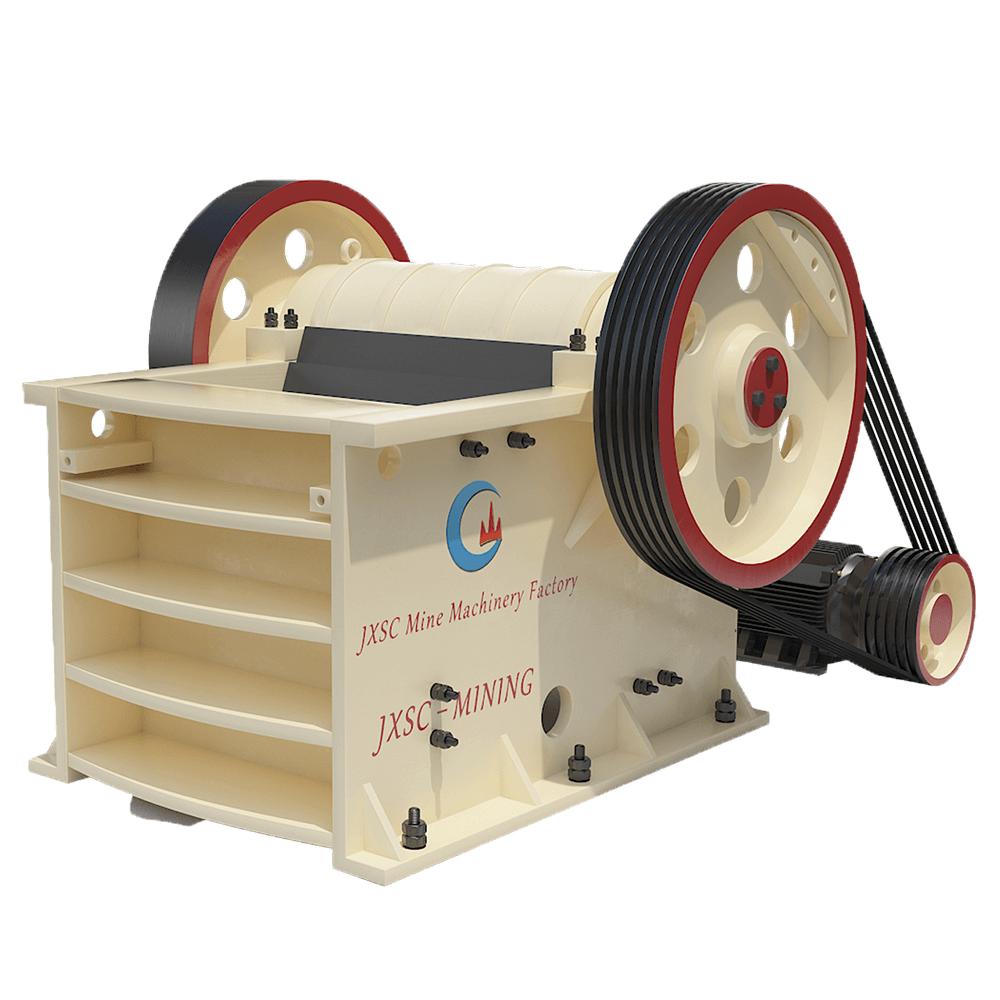

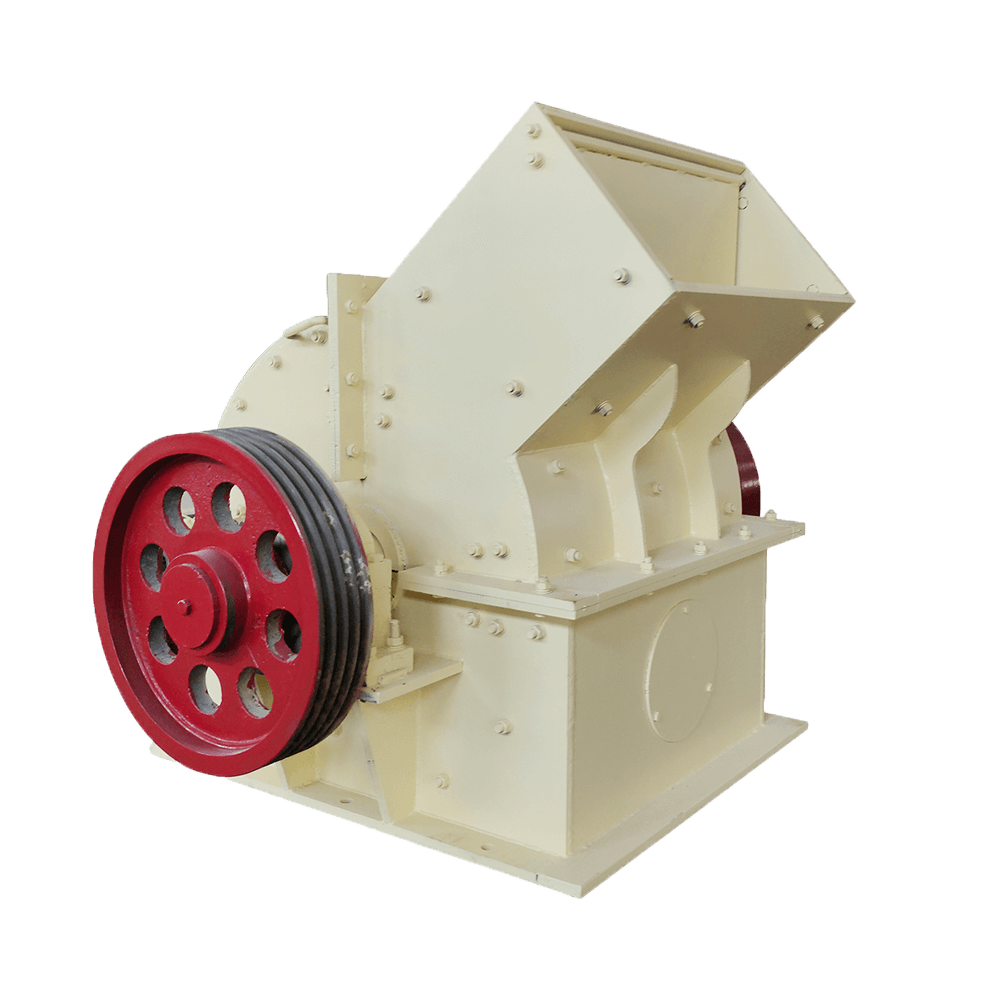

1.Crushing stage: jaw crusher, hammer crusher

First, the jaw crusher crushes the stone to 0-40mm, and then it is sent to the hammer crusher by the belt conveyor for fine crushing. The hammer crusher crushes the material from the upper level to 0-10mm, and then sends it to the transfer silo by the belt conveyor.

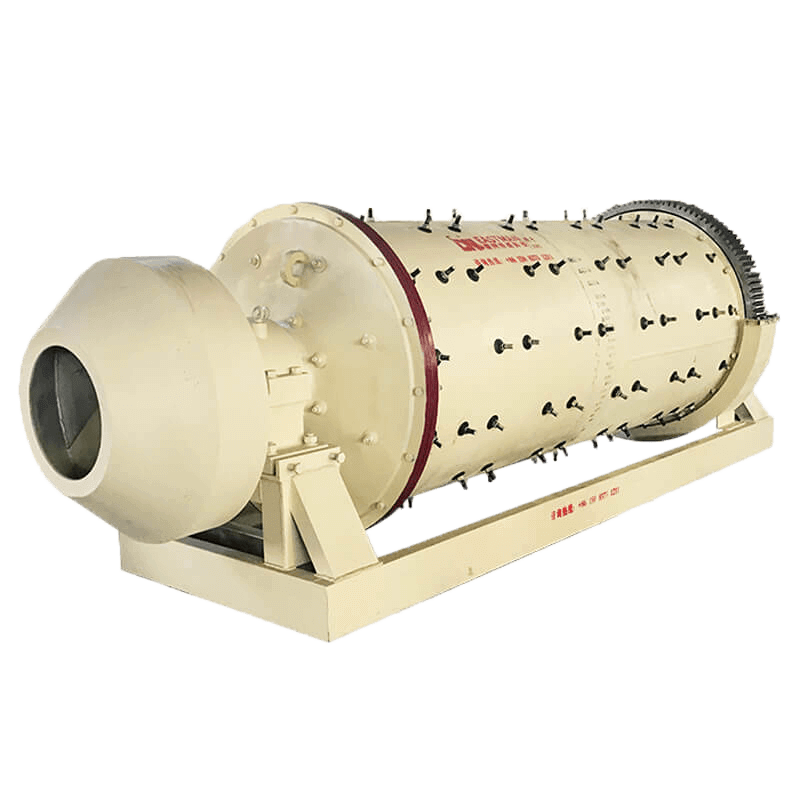

2.Grinding & classifying stage: ball mill, spiral classifier

The silo is used to store fine minerals of 0-10mm. There is an electromagnetic vibrating feeder below it to feed the materials evenly into the ball mill. The ball mill is used to crush the final particle size to extremely fine size. When used in conjunction with the classifier, it can ensure that most of the final particle size is 0-200 mesh.

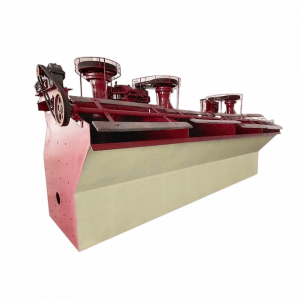

3.Flotation stage: mixing tank, flotation machine

Mix the 0-200 mesh slurry and chemicals evenly in the mixing tank and then transport them to the flotation machine. Three-stage flotation is adopted: rough flotation, sweep flotation, and fine flotation to finally obtain high-quality lithium concentrate.

High-grade lithium concentrate can be obtained through these equipment we provide, and the recovery rate is very objective. The customer’s 24tpd flotation plant is undergoing testing before switching to large-capacity production. For future large capacity, you can consider adding a dehydration system machine to obtain dry lithium concentrate and dry tailings while recovering water. Flotation effectively recovers ores of industrial value. Due to the different properties of spodumene or lepidolite ore in different deposits, we support customized lithium flotation process plant and equipment, contact us online for details!

Main Equipment

Product Name | Model No. | Quantity (Set) |

Jaw crusher | PE150*250mm | 1 |

Belt conveyor | DT75-500 | 2 |

Hammer crusher | PC400*300 | 1 |

Electromagnetic vibration feeder | GZ1 | 1 |

Ball mill | MQZ0918 | 1 |

Spiral classifier | FG-5 | 1 |

Slurry pump | 2/1.5 | 2 |

Mixing tank | 1m | 2 |

Water pump | IS32 | 1 |

Flotation Machines | SF0.37 | 12 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.