Mineral Processing » Solutions » Tailings Processing

tailings Processing

After the ore is processed through mineral processing, the main useful components are enriched into concentrates, while other residual substances are called tailings.

The tailings processing solution aims to dewater or reprocess various ore tailings. JXSC supports customized tailings processing plants and equipment according to the properties of mineral tailings.

Tailings processing Solutions

Tailings processing is an important stage in the ore beneficiation process, which aims to treat the waste and residue generated in the beneficiation process to reduce environmental pollution or resource waste and maximize the recovery of valuable minerals. The tailings processing solutions mainly depends on the type of ore, beneficiation process, environmental and regulatory requirements.

1. Flotation tailings treatment

If the tailings contain highly valuable minerals, it involves a re-flotation process. This method is often used to process complex ores. The process is mainly designed according to the tailings’ mineral composition and flotation conditions.

2. Tailings dry stacking

Dehydration and solid-liquid separation are usually carried out by dewatering screens, hydrocyclones, thickeners, filter presses and other tailings processing equipment. After the tailings are dewatered and dried, it become solid and dry-stacked in a specific stockpile. It is especially suitable for treating tailings with high water content, reducing water content and reducing waste volume.

3. Tailings reprocessing

Tailings may contain incompletely separated valuable minerals, which can be further extracted and utilized. For example, gravity separation, flotation, magnetic and electrostatic separation to extract rare metals or minerals from tailings. The tailings reprocessing method is suitable for the re-separation of various tailings, including gold, iron, lead-zinc, copper, fluorite, tungsten, phosphorus, graphite, bauxite tailings, etc. Among them, a centrifugal concentrator is usually used to process gold tailings, so that valuable ore can be separated due to its higher density.

4. Tailings Cyanide/ Heap leaching method

It involves using water or other solvents to dissolve target minerals to recover valuable metals or compounds. This is generally applicable to the treatment of tailings containing soluble metals, chemicals or other valuable minerals, such as low grade gold, silver and other metal ore tailings processing.

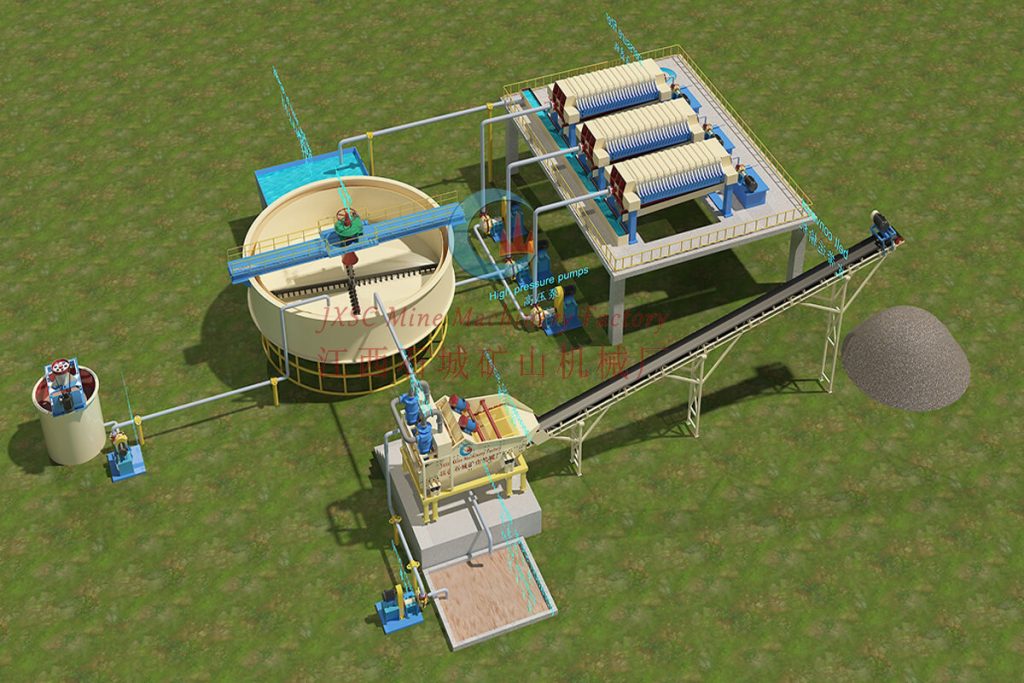

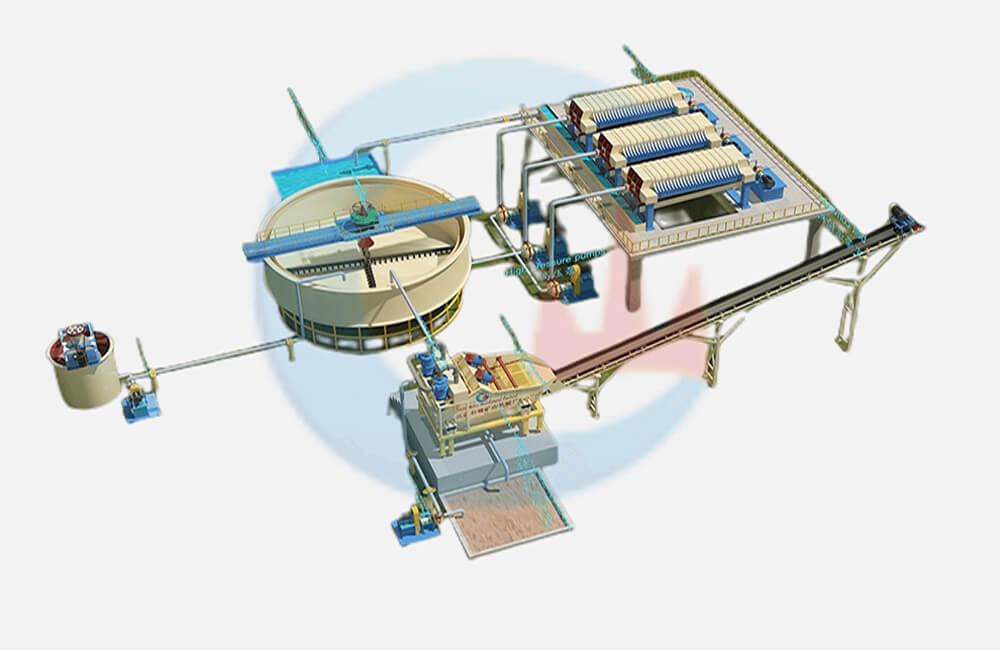

Tailings Processing Plant

Tailings dry stacking process

Tailings Dewatering Process | Moisture content |

| Thickener + hydrocyclones + belt filter | 15%~18% |

| Thickener + ceramic filter | <10% |

| Thickener + box filter press or vertical filter press | 15%~25% |

| Cyclone + thickener + multifrequency screen | <10% |

Thickener + hydrocyclone + belt filter press: This equipment combination and process flow are suitable for recovering medium and coarse tailings, and continuous production. However, in production and operation, the power consumption is large, the cost is high, and the investment is large.

Thickener + ceramic filter: This process is suitable for dewatering of medium and fine-grained tailings, but it isn’t easy to dehydrate the coarse-grained and -0.037mm particle size accounting for 80% of the pulp. Continuous production can be realized, and the water content of the finished product is low. But its equipment investment is high, and the ceramic plate is easy to block, so it is generally used for concentrate dehydration.

Thickener + box filter press or vertical filter press: This process is suitable for the dehydration of medium and fine-grained materials, and it can still be used when the particle size of -0.037mm accounts for 95%. Among them, filter cloth and pump flow parts are vulnerable and must be replaced on time. Vertical filter presses are expensive, have low moisture content, and are often used for concentrate dehydration.

Hydrocyclone + thickener + multi-frequency screen: This combined process can almost complete the dehydration operation of all minerals within 80%-325 mesh. The process has almost no wearing parts, and its running cost is low. The high-frequency fine screen uses a built-in wear-resistant polyurethane composite screen, and its life is 3-10 times longer than that of traditional metal screens.

200 TPD Tailings Processing Plant

250TPH Flotation Tailings Tantalum Niobium Separation Process

JXSC tailings processing plant has the characteristics of excellent materials, reasonable design and structure, easy operation, and high economic return rate. Our tailings processing solutions are suitable for all kinds of tailings with re-separation value, including iron ore, gold, lead-zinc, copper, lithium, tin, manganese, tungsten, fluorite ore, and other mine tailings processing solutions. We support configuring a full set of tailings treatment solutions and equipment for you to maximize the extraction of valuable minerals while achieving environmentally friendly mineral processing. Free consultation and quote!

Related equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.