High Pressure Hydraulic Roll Crusher

Capacity: 30-150 T/H

Discharge size: <5 mm

Application: High-pressure hydraulic roll crusher is primarily used for medium and fine crushing of ores and rocks such as river pebbles, granite, basalt, limestone, bluestone, diabase, weathered sand, marble, iron ore, quartz, and calcite.

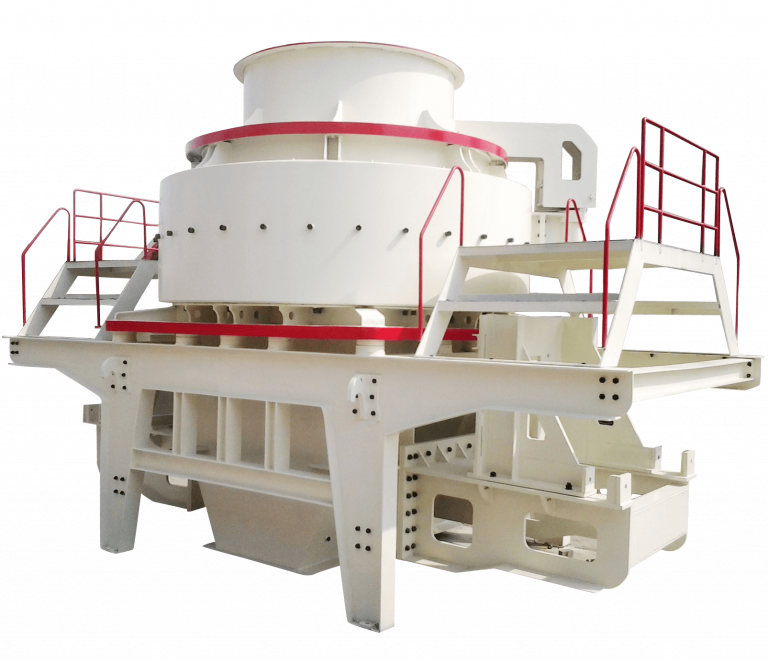

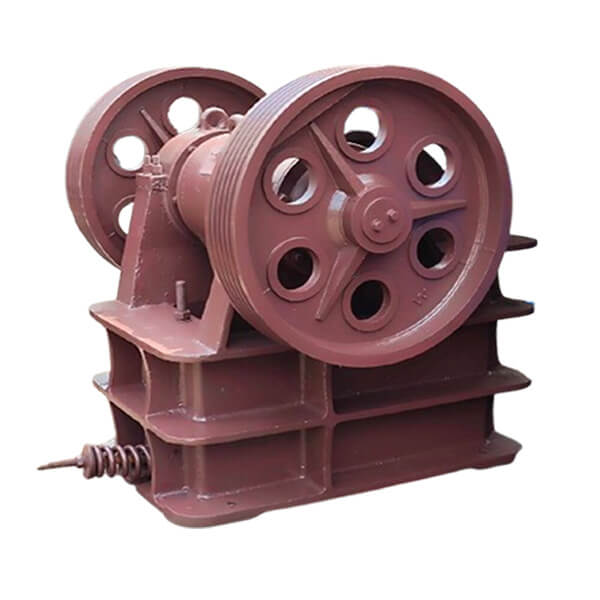

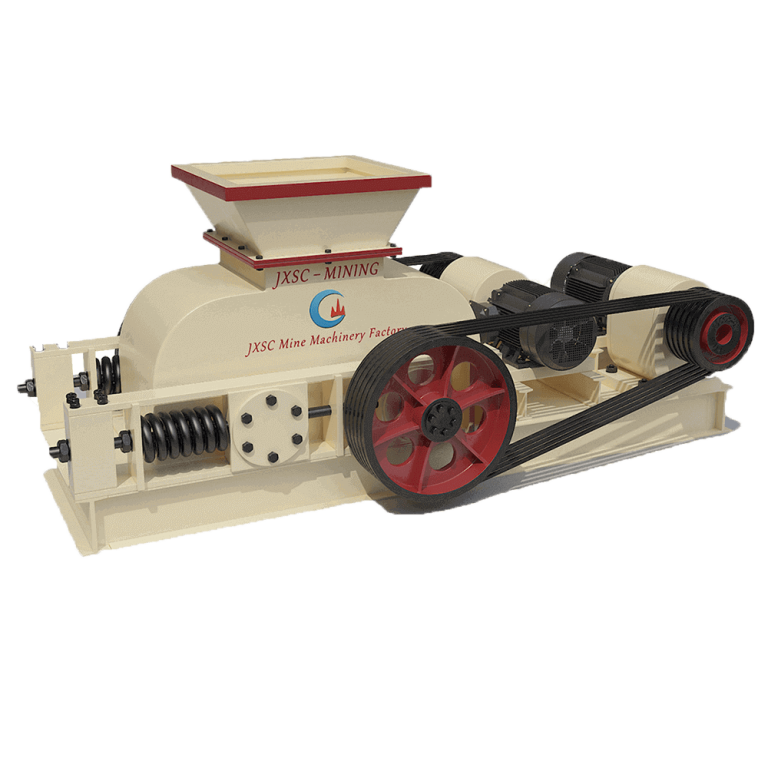

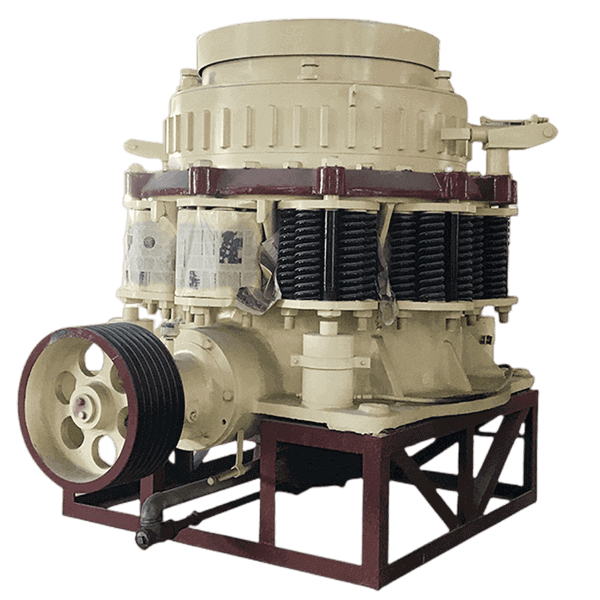

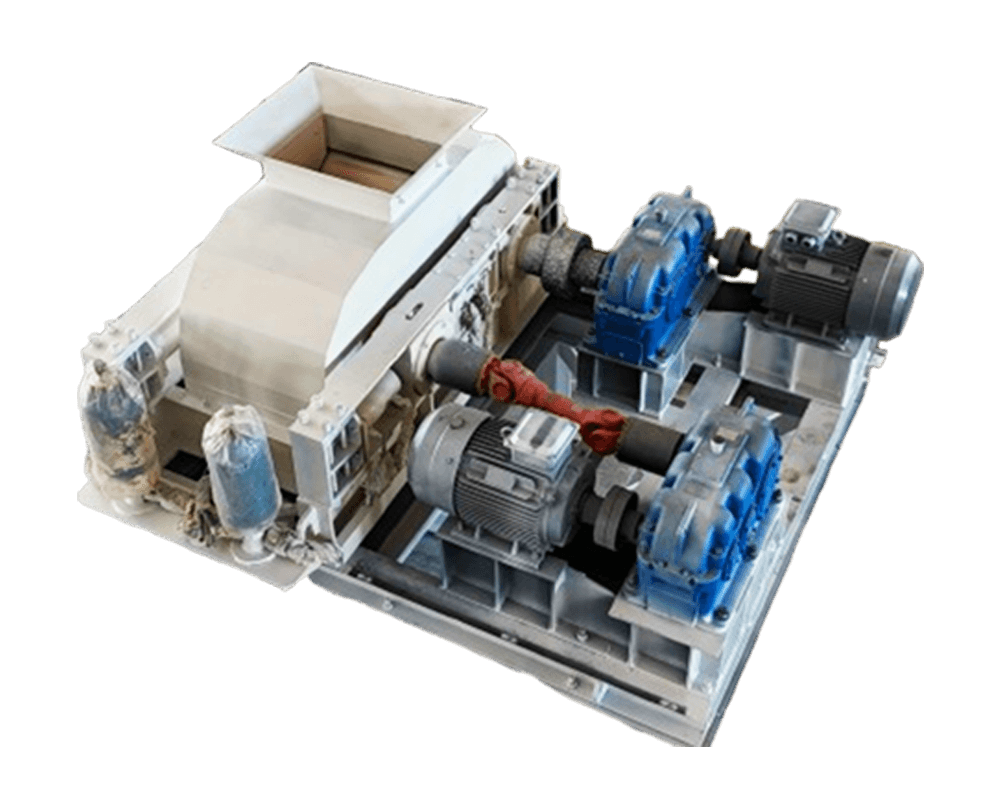

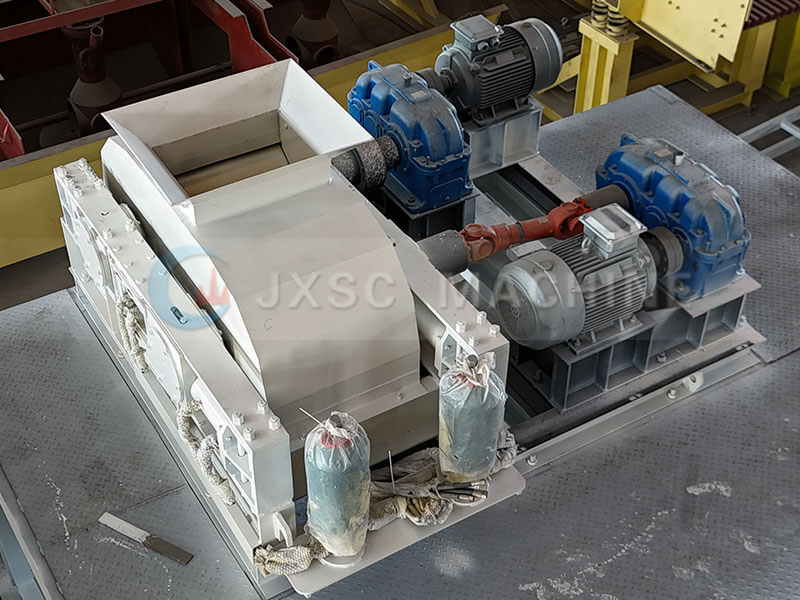

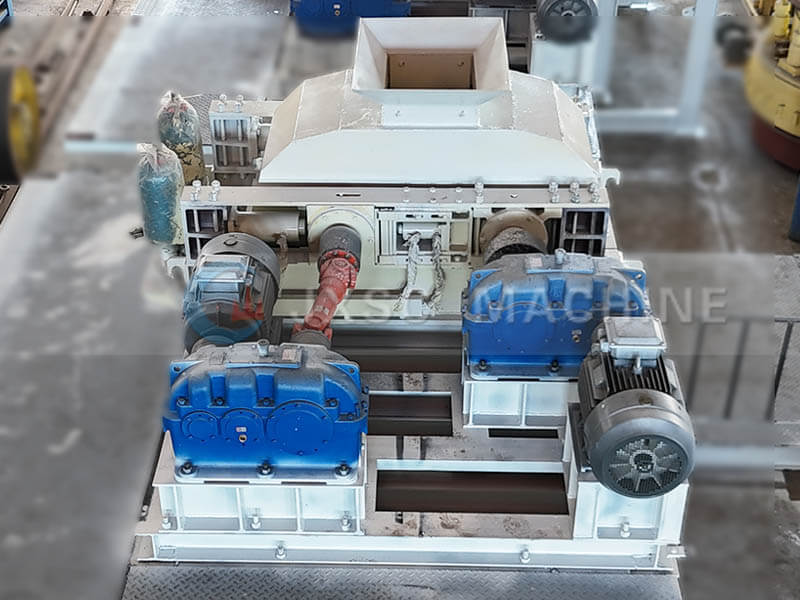

Products display

Introduction of High Pressure Hydraulic Roll Crusher

A high-pressure hydraulic roll crusher, also known as a high-pressure roller mill or hydraulic roller sand making machine, is an advanced crushing equipment that utilizes high-pressure laminated crushing technology. It is designed specifically for the fine crushing and shaping of medium-to-high-hardness materials. It utilizes dual rollers rotating in opposite directions to generate extrusion pressure and a laminated crushing effect, achieving efficient particle size reduction and optimizing particle shape. This high-pressure roller crusher is widely used in industries such as mining, metallurgy, chemicals, and building materials.

This high-pressure roller crusher integrates technologies such as hydraulic stepless adjustment, wear-resistant roller surface, and intelligent overload protection system, and has the advantages of low energy consumption, high particle quality, and controllable dust and noise. It provides a low-energy crushing solution for medium-hardness materials (compressive strength ≤250 MPa), such as river pebbles and granite, in the building materials and infrastructure sectors.

Its high-quality finished product can efficiently meet the needs of applications such as manufactured sand, concrete aggregate, and roadbed filler, achieving both improved product quality and optimized production costs.

Principle and structure of high pressure hydraulic roll crusher

Working principle

Material falls from the feed port between two rollers. The counter-rotating rollers generate a compressive and laminating crushing effect, squeezing and grinding the material between the rollers before it naturally falls. A hydraulic system monitors the pressure between the rollers in real time and adjusts the gap between the rollers to control the particle size of the material. If unbreakable material (such as metal blocks) is encountered, the moving rollers instantly retreat to prevent damage. The crushed material achieves uniform particle size, resulting in a cubic, low-flake content.

Structural characteristics

- Roller: High-hardness alloy roller skin for superior wear resistance.

- Hydraulic system: Provides adjustable pressure to ensure stable crushing.

- Transmission: Motor + reducer drives the synchronous rotation of the two rollers.

- Adjustment: Manual or automatic adjustment of the roller gap.

- Frame: Heavy-duty steel construction for impact resistance and stability.

- Support bearing: sealed and lubricated design to ensure high-intensity operation stability.

why choose JXSC High Pressure Hydraulic Roll Crusher

features & Advantages

√ High efficiency and energy saving: Compared to traditional crushing equipment, the high-pressure double-roll crusher consumes less energy and achieves higher crushing efficiency.

√ Wear-resistant and durable: The roller surface is inlaid with special alloys or tungsten carbide, extending its service life by 2-3 times and reducing maintenance costs.

√ High-quality finished product: The output material has a uniform particle size and low over-crushing rate, making it suitable for high-quality aggregate production.

√ Intelligent control: Supports a PLC intelligent control system, enabling remote monitoring of parameters such as the roll gap, pressure, and current, enabling fully automated production.

√ Environmental protection: Due to its enclosed crushing chamber, it reduces dust and noise pollution.

√ Cost controllable: The only wearing parts are the roller surface and bearings, so the annual maintenance cost is low.

√ Flexible configuration: JXSC supports customized spring roller crushers or hydraulic roller sand making machines, both of which are green crushing solutions.

models & specifications

Name | Model | ||

2PGY-1000*800 | 2PGY-1200*1000 | 2PGY-1500*1000 | |

Grinding roller diameter | 1000mm | 1200mm | 1500mm |

Grinding roller length | 800mm | 1000mm | 1000mm |

Max feed size | <25mm | <30mm | <30mm |

Max throughput | <25mm 120t/h | <30mm 230t/h | <30mm 300t/h |

Discharge size | <5mm | <5mm | <5mm |

Final product capacity | 30-60t/h | 60-100t/h | 100-150t/h |

Power | 45KW-90KW*2 | 90KW-110KW*2 | 160KW*2 |

Total weight | 18000KG | 28000KG | 31000KG |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.