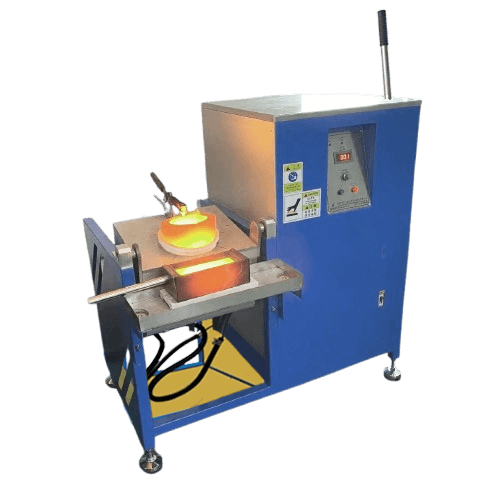

6-20 Kg Hand-Tilting Gold Furnace

- Maximum temperature: 1600°C

- Melting time: 3-6 minutes

- Melting capacity: 6kg, 8kg, 10kg, 15kg, 20kg available

The 6-20 kg hand-tilting gold furnace is a heating device designed for small-scale precious metal smelting. It is suitable for melting and casting ingots of gold, silver, platinum, copper and other metals and alloys.

Introduction of 6-20 Kg Hand-tilting Gold Furnace

The 6kg-20kg hand-tilting gold furnace is a thermal equipment specifically designed for small- to medium-scale precious and non-ferrous metal smelting. Its core feature is the manual tilting mechanism, allowing users to control the furnace’s tilt angle via a handle or lever, safely pouring molten metal into molds or ingot casting tanks. With capacities ranging from 6kg to 20kg, it utilizes IGBT high-frequency induction heating technology, coupled with silicon carbide graphite or zirconium oxide crucibles, to efficiently melt various metals and alloys such as gold, silver, copper, platinum, and karat gold, achieving a maximum operating temperature up to 1600°C. This hand-tilting gold melting furnace is suitable for jewelry processing, laboratories, precious metals and non-ferrous metals processing plants, and small recycling plants, balancing operational flexibility and cost-effectiveness.

The key technology lies in tilting stability. The center of gravity design and high-temperature resistant bearings ensure no metal splashing during tilting, while the refractory materials must withstand repeated thermal expansion and contraction. This hand-tilting gold furnace is equipped with wheels for easy movement. Integrating three core functions—induction heating, temperature control, and manual tilting—this equipment features a manual tilting wheel system or a hand crank mechanism, allowing operators to easily control the tilting angle (typically adjustable from 0-90°) using mechanical levers, achieving splash-free casting of molten metal.

Compared to fully automatic tilting furnaces, its significant advantages include lower operating barriers, smaller footprint, and lower cost. It supports continuous 24-hour operation and can achieve rapid melting in 3-6 minutes. Compared to ordinary stationary furnaces, the hand-titling gold furnace capacity range precisely covers the needs of high-frequency, small-batch production, avoiding material waste. The hand-tilting design eliminates the need for complex automation systems, reducing maintenance difficulty, making it a relatively low-tech melting and casting equipment for precious metal alloys.

Core Functions:

- Jewelry making and restoration: Used to melt down old gold jewelry and scraps, recasting them into new designs, supporting high-purity recycling.

- Precious metal recycling and refining: Extracting gold and silver from small-scale electronic waste or industrial waste processing, such as recovering gold-plated components from old circuit boards or platinum group metals from industrial catalysts.

- Laboratory research: In materials science experiments, precise control of the molten state of small amounts of metal is required; the manual pouring furnace facilitates operation and recording.

- Small-scale ingot production: Helps precious metal traders or small processing plants melt recycled metal particles into standard ingots for easy trading and storage.

- Customized metal crafts: Artists or workshops can utilize its flexible pouring function to create metal sculptures, jewelry molds, or precision metal components.

Principle of 6-20 Kg Hand-tilting Gold Furnace

Working principle

The working principle of a 6-20 kg hand-tilting gold melting furnace is to melt precious metals using electrical heating, and then manually tilt the furnace to complete the casting. After the power is turned on, the built-in high-efficiency heating elements (such as silicon carbide rods or resistance wires) begin to heat up. Heat is transferred through the high-temperature resistant inner wall of the furnace to the crucible containing the precious metal, which gradually melts under high temperature. When the temperature sensor detects that the metal has completely melted, the operator rotates the manual tilting device to tilt the furnace, allowing the molten metal to flow smoothly into the pre-prepared mold along the guide channel. After casting is complete, the furnace is returned to its original position, the power is turned off, and it is allowed to cool naturally.

Structural features

- Heating System: The core component is a high-temperature resistant heating element or induction coil, coupled with a PID temperature control module (error ±1°C).

- Crucible Assembly: Typically made of alumina or graphite, corrosion-resistant and non-reactive with platinum.

- Cooling Device: Water chiller or tap water (pump) ensures the equipment does not overheat during prolonged operation.

- Safety Features: Leakage protection, over-temperature alarm, and emergency stop switch; some models are equipped with an observation window to monitor the melting state.

- Frame and Tilting Mechanism: A stainless steel outer shell supports the entire unit; manual levers or gear sets achieve precise crucible tilting.

why choose JXSC 6-20 Kg Hand-tilting Gold Furnace

features & Advantages

√ High cost-effectiveness: Compared to automatic furnaces, manual tilting gold melting furnaces are more affordable, saving 30%~50% on equipment investment. Suitable for small and medium-sized enterprises or individual workshops, they still guarantee stable smelting results.

√ Easy operation: No complex training required. The ergonomically designed manual tilting mechanism allows a single person to easily control the tilt of the 20kg furnace body with a tilting accuracy of ±1mm.

√ Convenient maintenance: Removable refractory lining and standardized heating elements result in low replacement costs.

√ Flexible multi-metal smelting: By changing the crucible and adjusting parameters, it can process more than 10 metals, including gold, silver, copper, aluminum, platinum, and palladium, meeting diverse production needs.

√ Space-friendly: The tabletop design has a small footprint, suitable for compact working environments.

√ Strong continuous production capacity: Supports 24-hour uninterrupted operation. The furnace body insulation layer and cooling system design ensure long-term operational stability.

√ Energy-saving and environmentally friendly: Precise matching of 6, 8, 10, 15, and 20kg capacities reduces waste heat, achieving an energy utilization rate of over 85%.

√ Simple maintenance: Heating elements and refractory linings can be quickly replaced, resulting in low maintenance costs and extended equipment lifespan.

models & specifications

Model No. | JXSC-TF6 | JXSC-TF8 | JXSC-TF10 | JXSC-TF15 | JXSC-TF20 | |

Voltage | 380V 50Hz 3 phases | |||||

Power | 15KW | 20KW | 20KW | 25KW | 30KW | |

Max Temp | 1600℃ | |||||

Melting speed | 2 – 5 Min. | 3 – 6 Min. | 3 – 6 Mins | 3 – 6 Mins | 3 – 6 Mins | |

Temp Accuracy | ±1°C (optional) | |||||

Temperature detector | PID Temperature Control / Infrared pyrometer (Optional), Water temperature: 18-28℃ | |||||

Capacity (Gold) | 6KG | 8KG | 10KG | 15KG | 20KG | |

Application | Gold, K-gold, Silver, copper, and other alloys (platinum, palladium, rhodium furnace are customized.) | |||||

Heating method | Germany IGBT Induction heating technology | |||||

Cooling type | Water chiller(sold separately) or Running water (water pump) | |||||

Dimensions | 1150x490x1120mm | 1250*650*1150mm | ||||

Net Weight | approx. 120kg | 150KG | ||||

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.