Mineral Processing » Equipment » PE Jaw Crusher

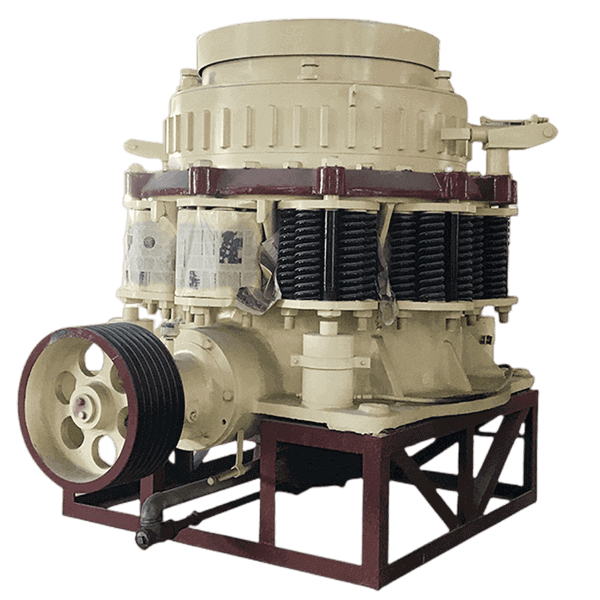

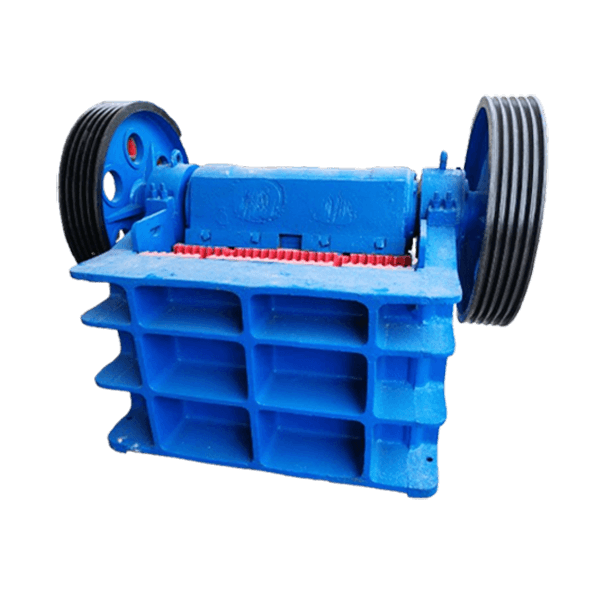

PE Jaw Crusher

Capacity: 1-1120 TPH

Max feeding size: 125-1200 mm

Application: PE jaw crushers (compound pendulum jaw crushers) are widely used in mining, aggregate production, construction waste processing, metallurgy, cement production, highway and railway construction, water conservancy projects, and other industries. It is an indispensable primary crushing equipment for sand, gravel, metal, and non-metal mineral processing plants such as iron ore, gold ore, copper ore, limestone, diamond, granite, columbite-tantalite, antimony ore, nickel ore, lead-zinc ore, tin ore, and other sand and gravel, metal, and non-metal mineral processing plants.

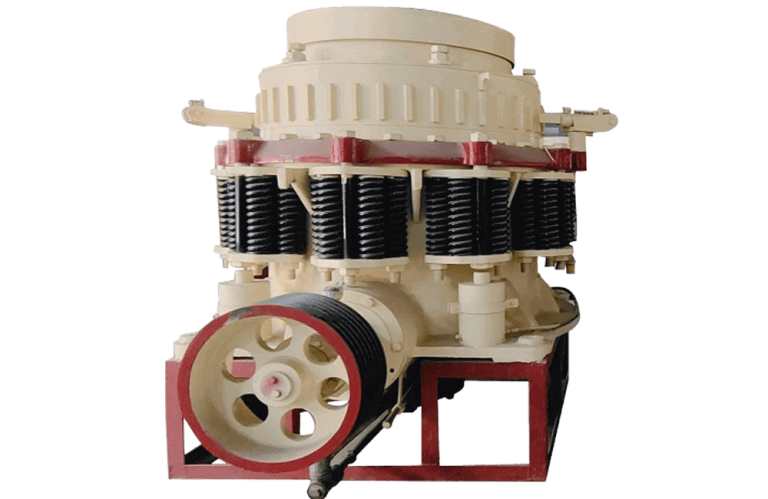

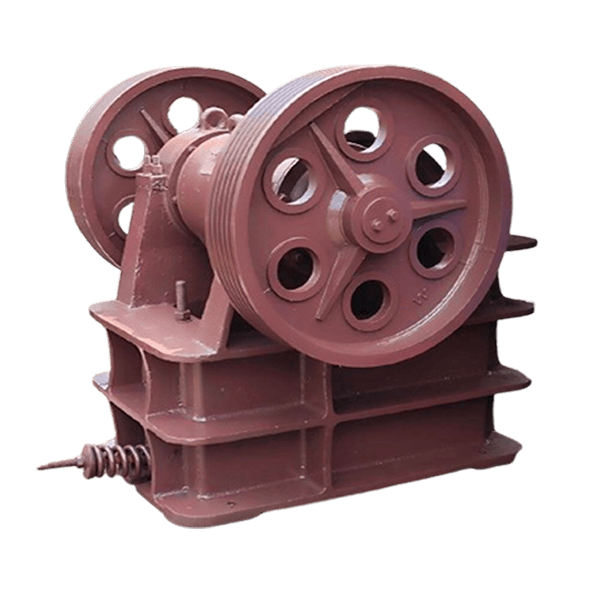

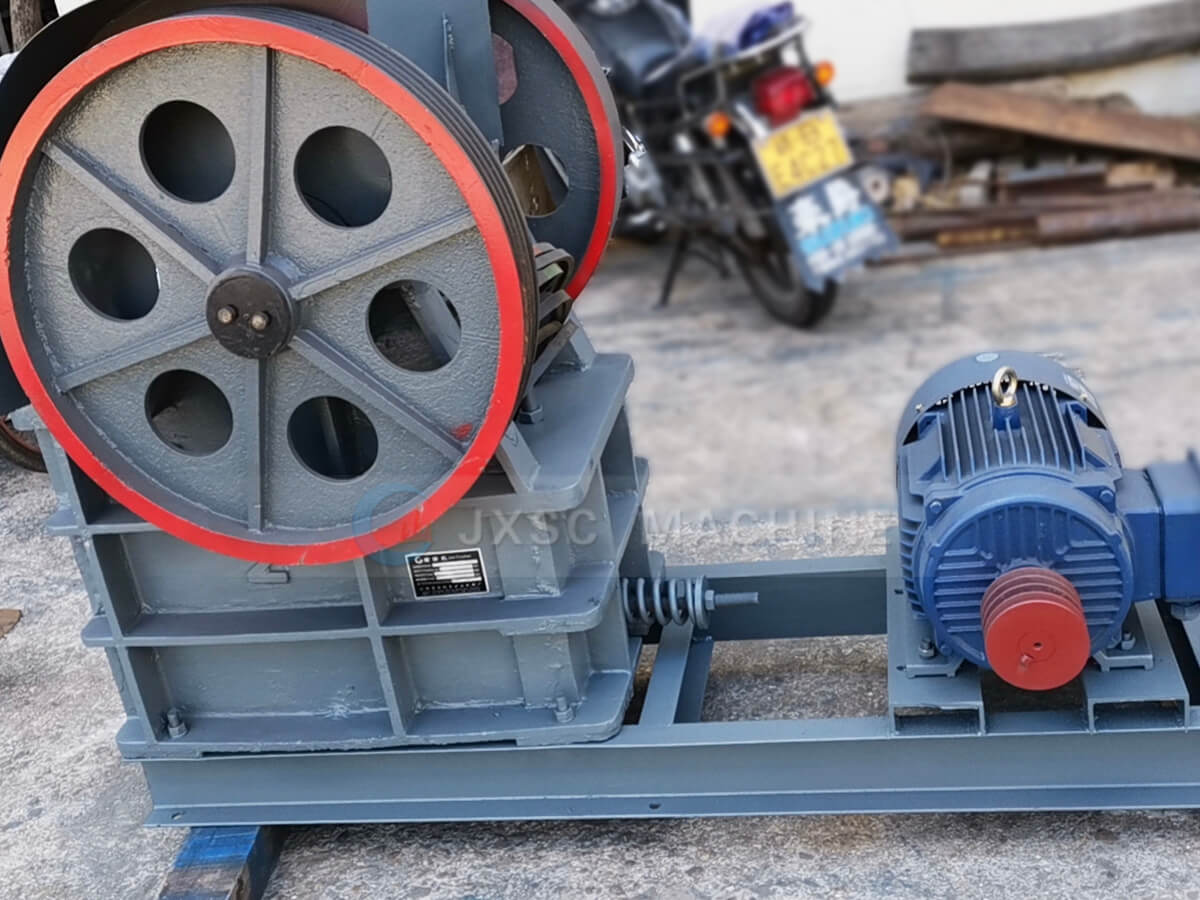

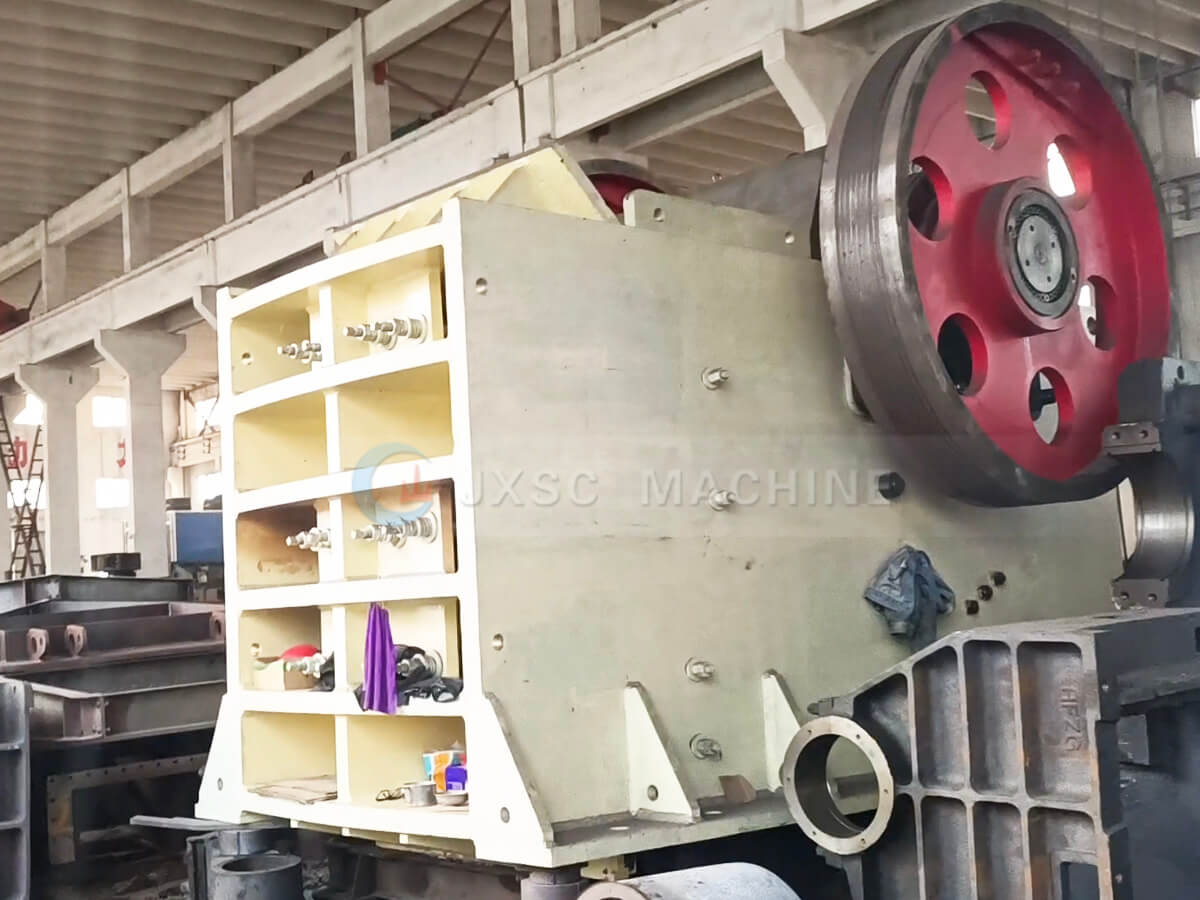

Products display

Introduction of PE Jaw Crusher

The PE jaw crusher, coarse jaw crusher, is short for a compound pendulum jaw crusher. The “PE” stands for “Primary Crusher,” representing its primary crushing function in the crushing production line. It is a widely used primary/coarse crushing machine in industries such as mining, construction, metallurgy, and infrastructure construction. Through the periodic squeezing and grinding action of the fixed and movable jaw plates, it crushes large materials to medium particle size, mainly used for coarse and medium crushing of various ores and rocks with a compressive strength not exceeding 320MPa. It features a large crushing ratio and high output (production capacity covers 1-1120t/h). It is especially suitable for the first-stage crushing in sand and gravel aggregate production plants, metal mines, or non-metallic mineral processing plants, such as granite, basalt, iron ore, gold, copper, manganese, chromium ore, tin ore, lithium ore, river pebbles, limestone, and other hard materials. The JXSC PE jaw crusher adopts an optimized V-shaped crushing chamber design, high-strength materials, and can be equipped with electric motor or diesel drive.

Hard rock coarse crushing Solution

As the primary crushing equipment in a production line, it can provide raw material with the required particle size for subsequent processes (fine crushing, screening, and grinding). We can also customize various types of jaw crushers according to your mine characteristics or requirements, such as PEX fine jaw crusher, European-style jaw crusher (PEV), or lab jaw crusher (PEF). The PE series jaw crusher can adapt to various harsh mining and sand and gravel processing conditions, and is also recognized in the market as a core industrial crushing equipment known for its high cost-effectiveness and reliability.

Core Applications

- Mining: Processes hard ores such as granite, basalt, and iron ore, serving as a core piece of equipment in the coarse crushing stage.

- Construction aggregate production: Crushes raw materials such as river pebbles and limestone to provide standard aggregates for concrete and asphalt pavements.

- Metallurgical industry: Crushes metallurgical waste such as steel slag and coke, enabling resource recycling.

- Infrastructure construction: Used for crushing and processing in large-scale engineering projects such as highways, railways, and bridges to meet engineering strength requirements.

- Solid waste treatment: Crushes construction waste and concrete blocks to achieve resource recovery.

- Sand and gravel quarries: Produces manufactured sand on a large scale, replacing natural sand and alleviating resource shortages.

- Laboratory: Custom small-scale PE jaw crushers for geological and mineral research, analysis, and other research using lab mineral samples.

Structural features & Working principle Of PE Jaw Crusher

Working principle

The core of the PE jaw crusher is kinetic compression crushing, with a continuous cycle of compression-crushing-discharge. The motor drives the eccentric shaft to rotate via a pulley, causing the movable jaw plate to perform periodic reciprocating motion. When the movable jaw plate approaches the fixed jaw plate, the material is compressed and crushed within the crushing chamber. When the movable jaw plate retracts, the crushed material is discharged from the discharge port under gravity. The discharge particle size is controlled by adjusting the discharge port gap (shim-type design). The equipment adopts a double-pendulum structure, resulting in a more optimized moving jaw trajectory, better crushing efficiency, and reduced over-crushing of materials.

Structural features

why choose JXSC PE Jaw Crusher

features & Advantages

√ High efficiency and energy saving: Optimized motion trajectory and reasonable crushing chamber shape result in a large crushing ratio and energy consumption reduction of over 20%.

√ Long service life of wearing parts: High manganese steel jaw plates + cast steel moving jaw ensure durable and wear-resistant core components.

√ Convenient maintenance: Concentrated lubrication points allow for toggle plate replacement without disassembling the equipment.

√ Wide material adaptability: Capable of crushing not only conventional ores and rocks and other hard materials, but also sticky and wet materials with a moisture content of less than 8%.

√ Precise particle size control: A precise discharge port adjustment system with a wide adjustment range meets the requirements of various engineering projects.

√ Environmentally friendly and low noise: Operating noise ≤85dB, compatible with pulse dust collectors, meeting national environmental protection standards.

models & specifications

Model | Feeding size(mm) | Max feeding size(mm) | Discharging Range size(mm) | Capacity (t/h) | Motor power(kw) | Weight (t) | Overall dimension(LxWxH)(mm) |

PE 150×250 | 150×250 | 125 | 10-40 | 1-3 | 5.5 | / | 760×700×860 |

PE-250*400 | 250*400 | 210 | 20-80 | 5-20 | 15 | 2.8 | 1450x1315x1296 |

PE-400*600 | 400*600 | 340 | 40-100 | 16-60 | 30 | 6.65 | 1565x1732x1586 |

PE-500*750 | 500*750 | 425 | 50-100 | 40-110 | 55 | 11.73 | 1890x1916x1870 |

PE-600*900 | 600*900 | 500 | 65-180 | 80-180 | 55-75 | 16.13 | 2305x1840x2298 |

PE-750*1060 | 750*1060 | 630 | 80-180 | 110-320 | 90-110 | 28 | 2450x2472x2840 |

PE-800*1060 | 800*1060 | 680 | 100-200 | 140-340 | 90-110 | 30 | 2610x2556x2800 |

PE-870*1060 | 870*1060 | 750 | 170-270 | 180-360 | 90-110 | 31.22 | 2660x2556x2800 |

PE-900*1060 | 900*1060 | 780 | 200-290 | 200-380 | 90-110 | 31 | 2690x2556x2800 |

PE-900*1200 | 900*1200 | 780 | 95-225 | 220-450 | 110-132 | 49 | 3335x3182x3025 |

PE-1000*1200 | 1000*1200 | 850 | 195-280 | 280-550 | 110-132 | 51 | 3435x3182x3025 |

PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 400-800 | 160-220 | 100.9 | 4200x3732x3843 |

PE-1500*1800 | 1500*1800 | 1200 | 210-360 | 525-1120 | 280-335 | 132 | 5100x4700x4300 |

Frequently Asked Questions

FAQs About Buy PE Jaw Crusher

The PE series has a higher processing capacity (1-1200 TPH) and is mainly used for primary crushing. The PEX series has a processing capacity of 10-140 TPH, a larger crushing ratio, and is suitable for fine crushing.

It is not recommended. The optimal particle size for PE series products is generally 20-360 mm; finer particles require PEX.

Suitable for materials with a hardness ≤320MPa, such as granite, basalt, iron ore, lithium, chromium, tin, copper, lead-zinc, and limestone. Specific selection should be based on the material’s characteristics and moisture content.

A PE250×400 motor requires approximately 15kW, while a PE1200×1500 motor requires 160-220kW. Please refer to the parameter table above or contact our professional engineers for details.

Under normal operating conditions, the jaw plate has a lifespan of approximately 6-12 months. If handling highly abrasive materials, more frequent replacement is required. The exact frequency depends on the material hardness and throughput.

Yes, a custom-made steel frame base is required, which can be matched with a vibrating screen, feeder, and conveyor belt.

Based on the maximum feed particle size, target output, and output particle size requirements. For example, the PE-600×900 has a processing capacity of 80-180t/h. Refer to the equipment parameter table; contact JXSC for customization.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.