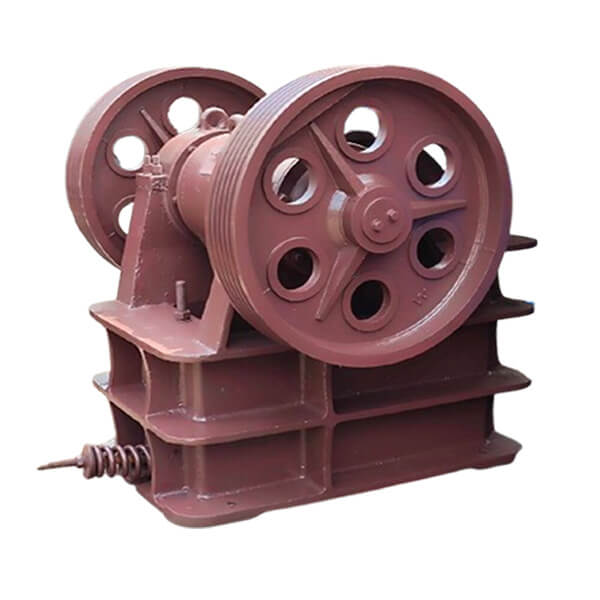

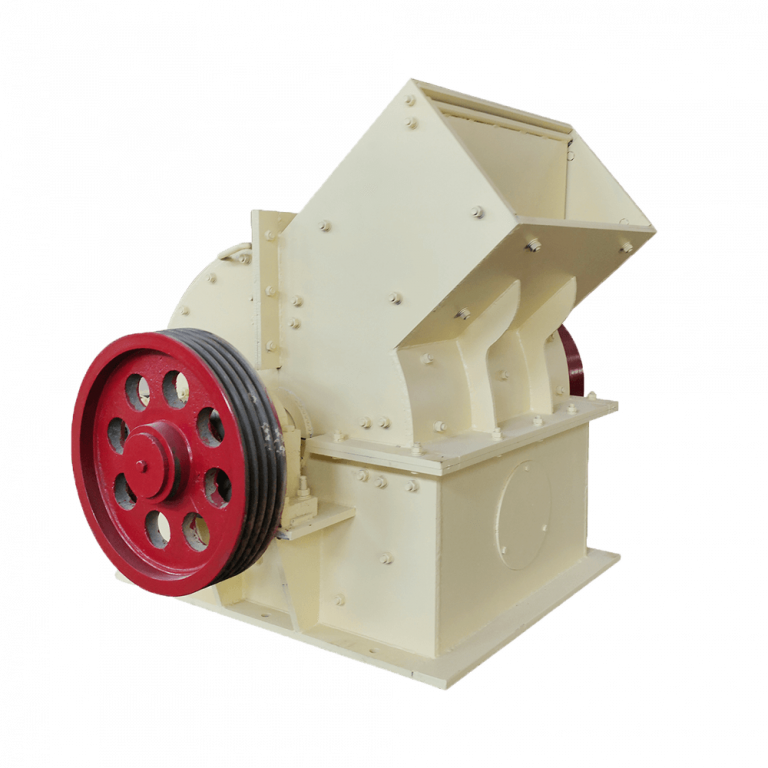

PEX Jaw Crusher

Capacity: 1-120t/h

Max feeding size: 125-300 mm

Discharging size: 10-140 mm

Application: The PEX jaw crusher is a key connecting piece of equipment in mineral processing plants from “coarse crushing → grinding”. It is widely used in the secondary fine crushing of ores, the fine preparation of high-quality sand and gravel for building material aggregates, the shaping of quartz sand aggregates, and closed-loop circulation systems in mineral processing plants, as well as the resource recovery of construction waste. Examples include the second or third stage crushing of various hard materials such as copper, gold, manganese, iron, lithium, diamonds, granite, limestone, tungsten ore, and feldspar.

Products display

Introduction of PEX Jaw Crusher

The PEX jaw crusher, also known as a fine jaw crusher, is a high-efficiency, small-to-medium-sized crushing equipment widely used in the medium- and fine-crushing stages of ores. Its offers finer output particle size adjustment and a higher crushing ratio. It is suitable for fine crushing of ores and rocks with medium to low hardness. For example, it is used as the second-stage crushing material in beneficiation plants for gold, iron, lead-zinc, chromium, manganese, copper, and lithium ores, providing suitable particle size raw materials for subsequent ball milling or flotation. It can also be used to crush limestone, gypsum, quartz sand, dolomite, etc., to produce aggregates for construction or cement raw materials. It adopts a single-toggle plate composite pendulum structure, with the upper part of the moving jaw directly suspended on an eccentric shaft, and its movement trajectory is elliptical, resulting in a better crushing effect.

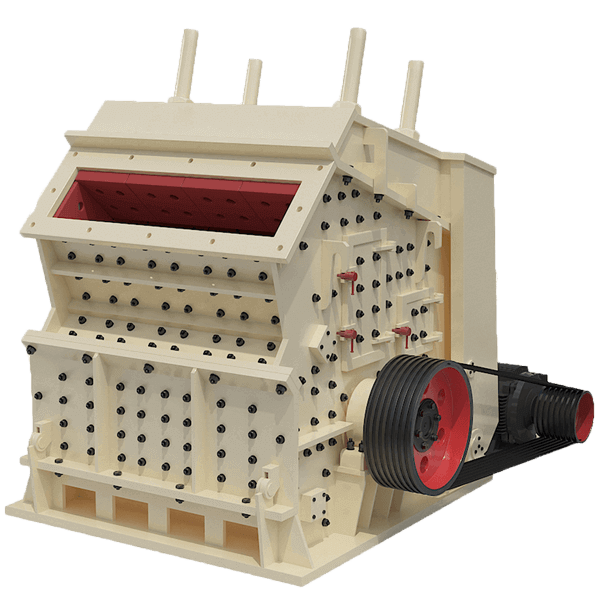

High-efficiency fine crushing solution

Compared to the coarse jaw crusher (PE series), the PEX series has an optimized cavity structure and dynamic jaw plate trajectory, has a smaller feed opening width, and often flexibly adapts to fixed production lines or forming mobile crushing stations in conjunction with screening and feeding systems. In mineral processing plants, PEX jaw crushers focus on “fine crushing and upgrading,” typically undertaking the secondary fine crushing of materials after primary crushing. Their unique “arc-shaped deep cavity” design extends material residence time, and combined with an adjustable discharge wedge device, achieves energy-saving effects of more crushing and less grinding, ensuring long-term stable operation.

The finished product from this fine jaw crusher has a uniform particle size, meeting the strength requirements of high-grade highways, offering excellent cost-effectiveness, and is also a key crushing equipment for manufactured sand and crushed stone aggregates.

Core Applications

- Metal Ore Beneficiation: Further crushing of materials such as gold, copper, and iron ores after medium crushing, improves the efficiency of subsequent grinding, flotation, or magnetic separation.

- Construction Aggregate Processing: In sand and gravel aggregate processing, the PEX fine jaw crusher can be used in conjunction with impact crushers or sand making machines to produce high-quality machine sand of 5-20mm, replacing natural sand in concrete mix design.

- Chemical and Ceramic Raw Material Crushing: Materials such as phosphate rock, pyrite, and feldspar can be crushed to a specific fineness.

- Laboratory Scenarios: Small PEX models can be used for mineral sample preparation in research institutions or universities.

- Environmental Recycling: Crushing and recycling of construction waste, such as the recycling of concrete blocks and waste bricks and tiles.

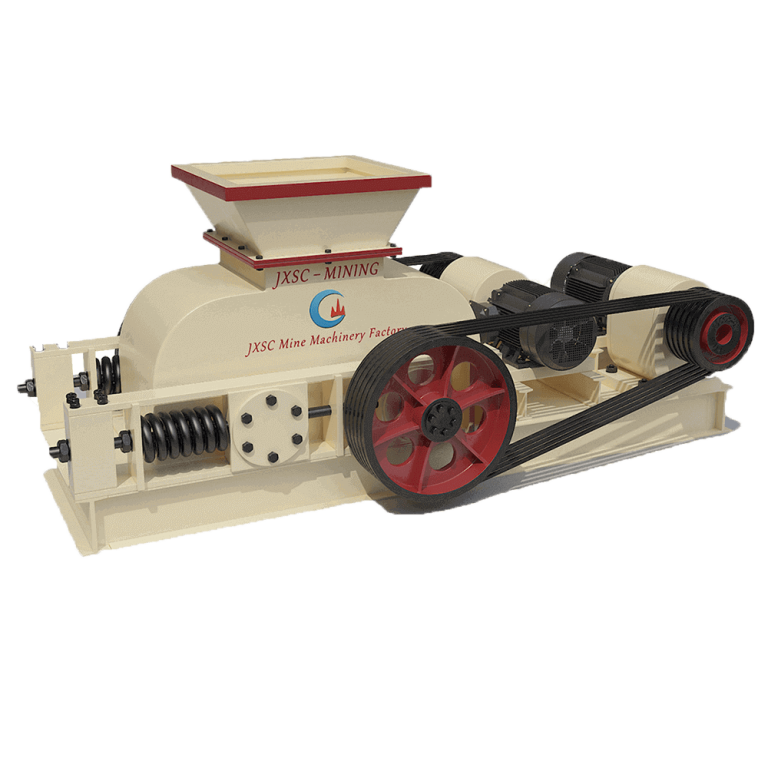

JXSC supports customizing various types of jaw crushers according to your mine characteristics or requirements, such as PE coarse jaw crusher, European-style jaw crusher (PEV), or lab jaw crusher (PEF). Both of which are fine crushing solutions for large, medium, and small ore processing production lines.

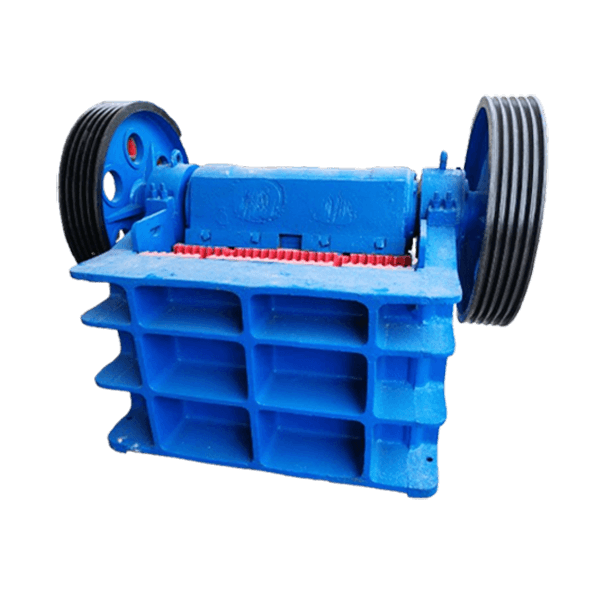

Structural features & Working principle Of PEX Jaw Crusher

Working principle

The PEX fine jaw crusher employs a reciprocating compression crushing method. A motor drives an eccentric shaft to rotate via a V-belt, causing the moving jaw to reciprocate along an elliptical trajectory. The upper end of the moving jaw is directly suspended from the eccentric shaft, while the lower end is connected to the frame via a toggle plate. When the moving jaw approaches the stationary jaw, the material is crushed under the action of compression and shearing forces. When the moving jaw retracts, the crushed material is discharged downwards due to gravity, while substandard particles continue to be compressed. With the continuous rotation of the motor, the moving jaw completes 30-50 reciprocating movements per second, achieving batch crushing of materials.

Structural features

why choose JXSC PEX Jaw Crusher

features & Advantages

√ High Crushing Efficiency: The PEX fine jaw crusher features an optimized crushing chamber structure with a deep cavity and no dead zones (material filling rate ≥95%), preventing material stratification within the crushing chamber.

√ Uniform Particle Shape: Deep cavity crushing reduces over-grinding, resulting in predominantly cubic finished products, beneficial for subsequent mineral processing.

√ High Durability: The jaw plates are made of high-manganese steel, which forms a hardened layer on the surface under impact loads, providing an impact wear resistance life of 6-12 months.

√ Stable Operation: The integral welded steel plate structure offers superior shock resistance compared to the bolted connection structure of the PE series, making it suitable for long-term, high-intensity operation.

√ Adjustable Discharge: The discharge port width is adjustable by adding or removing shims, covering a range of 10-140mm, allowing for quick adaptation to different finished product particle size requirements.

√ Low Cost: PEX models are typically equipped with wear-resistant alloy jaw plates, resulting in a longer lifespan for vulnerable parts compared to PE coarse jaw crushers, leading to lower maintenance costs.

√ Modular structure: The frame, crushing chamber, and power system of the PEX fine jaw crusher adopt a modular design, which reduces the weight by 10% compared with traditional equipment and can be quickly integrated into the tracked mobile crushing station.

models & specifications

Model | Feeding | Max feeding | Discharging | Capacity | Motor | Weight | Overall dimension |

PEX-150*250 | 150*250 | 125 | 10-40 | 1-3 | 5.5 | 2 | 896x745x935 |

PEX-150*750 | 150*750 | 120 | 18-48 | 8-25 | 15 | 3.5 | 1380x1658x1025 |

PEX-250*750 | 250*750 | 210 | 25-60 | 13-35 | 30 | 4.96 | 1545x1667x1330 |

PEX-250*1000 | 250*1000 | 210 | 25-60 | 16-52 | 30-37 | 6.5 | 1530x1992x1380 |

PEX-250*1200 | 250*1200 | 210 | 25-60 | 20-61 | 37-45 | 8.52 | 1900x2192x1430 |

PEX-300*1300 | 300*1300 | 250 | 20-90 | 25-95 | 55-75 | 12.6 | 1750x2320x1724 |

PEX-350*1200 | 350*1200 | 300 | 70-140 | 25-120 | 75 | 12.35 | 2162x2220x1723 |

Frequently Asked Questions

FAQs About Buy PEX Jaw Crusher

PEX is a fine crusher type with more uniform output, suitable for secondary crushing needs. It has a larger crushing ratio (PEX typically 4-8, PE only 3-5). The PE series focuses on coarse crushing and has a stronger ability to handle large pieces of ore. If the production line needs to meet both needs (such as coarse crushing + fine crushing), PE and PEX models can be used in series.

Depending on the model, it is typically between 125-300mm. Exceeding this limit may cause material blockage or equipment overload; pre-screening is recommended.

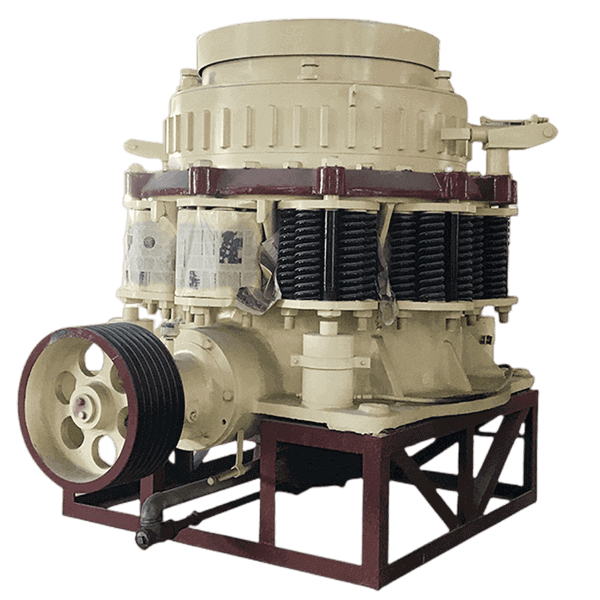

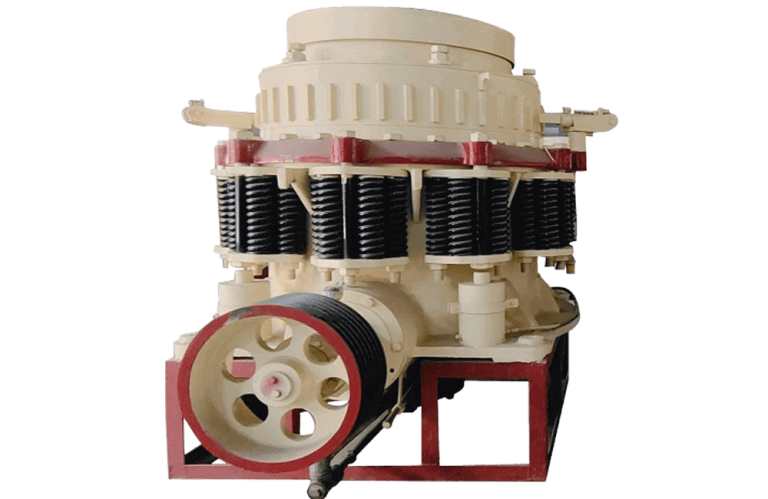

For small to medium-scale production (≤140t/h), the PEX jaw crusher offers better value for money, with a purchase cost 40% lower and simpler maintenance. However, cone crushers are more suitable for high-hardness materials (such as granite) and ultra-large capacities (up to 1450t/h). For specific selection advice, please contact us for configuration based on material hardness, budget, and requirements.

A PEX fine jaw crusher can handle wet, sticky materials with a moisture content ≤15%. However, the following measures should be taken to avoid clogging:

- Reduce the residence time of material in the chamber.

- Install a vibrating feeder for uniform feeding and avoid overload.

- Regularly clean the discharge port to prevent material agglomeration.

- Use wear-resistant jaw plates to reduce adhesion.

Under normal operating conditions, the jaw plate has a lifespan of approximately 6-12 months. If handling highly abrasive materials, more frequent replacement is required. The exact frequency depends on the material hardness and throughput.

Yes, a custom-made steel frame base is required, which can be matched with a vibrating screen, feeder, and conveyor belt.

An optional PLC control module is available, which can be linked to adjust the feeder speed, monitor bearing temperature in real time, and automatically stop the machine in case of abnormality.

Based on the maximum feed particle size, target output, and output particle size requirements. For example, the PE-600×900 has a processing capacity of 80-180t/h. Refer to the equipment parameter table; contact JXSC for customization.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.