Diamond ore beneficiation line refers to a collection of equipment used to process and refine ore, mainly used to separate and concentrate ore to obtain the required metal or mineral. Diamond ore can be divided into rock ore or sand ore, and its beneficiation line equipmentmainly include: crushing, washing, screening, and gravity separation machines. Diamonds can be separated from metal elements in metal ores through the beneficiation production line, and undergo a series of refining and purification processes to finally obtain high-purity metal products.

Diamond ore beneficiation equipment

There are two types of diamond mines. One is raw diamonds mined directly from the place of origin. The other is placer mining, which sifts diamonds washed out by rain like gold panning. Usually the content of diamonds in minerals is low, so diamonds need to be extracted through mineral processing. Among them, various special beneficiation equipment for diamond mines play a key role in converting rough stones into marketable gemstones.

1. Diamond ore crushing equipment

When the ore is in a larger block of rock diamond minerals and is a high-hardness metal ore, if precious diamonds need to be extracted from the ore, crushing equipment is used to reduce the particle size. Usually, jaw crushers, impact crushers and cone crushers are mainly used, each with unique features tailored to the hardness of diamond ore. Usually, jaw crushers can be selected for coarse crushing.

- And cone crushers are required for medium and fine crushing. If the cost is limited or the mine situation is concerned, impact crushers can also be selected as secondary crushing.

- Jaw crushers are very suitable for pre-crushing larger rocks because they use compression to break the material into a manageable size before further processing.

- At the same time, impact crushers use high-speed rotor impacts to further refine these lumps, which shatter the ore and release the diamonds with minimal damage.

2. Diamond ore washing equipment

Diamond minerals mined from underground usually have slime or other impurities on the surface. Trommel screens or rotary scrubbers are mainly used for washing equipment of diamond ore. They are mainly used for scrubbing, desludging, and screening of muddy ores before beneficiation. When the surface of the ore contains a large amount of mud, a rotary scrubber is required for the best cleaning effect. Otherwise, a trommel screen can be used instead.

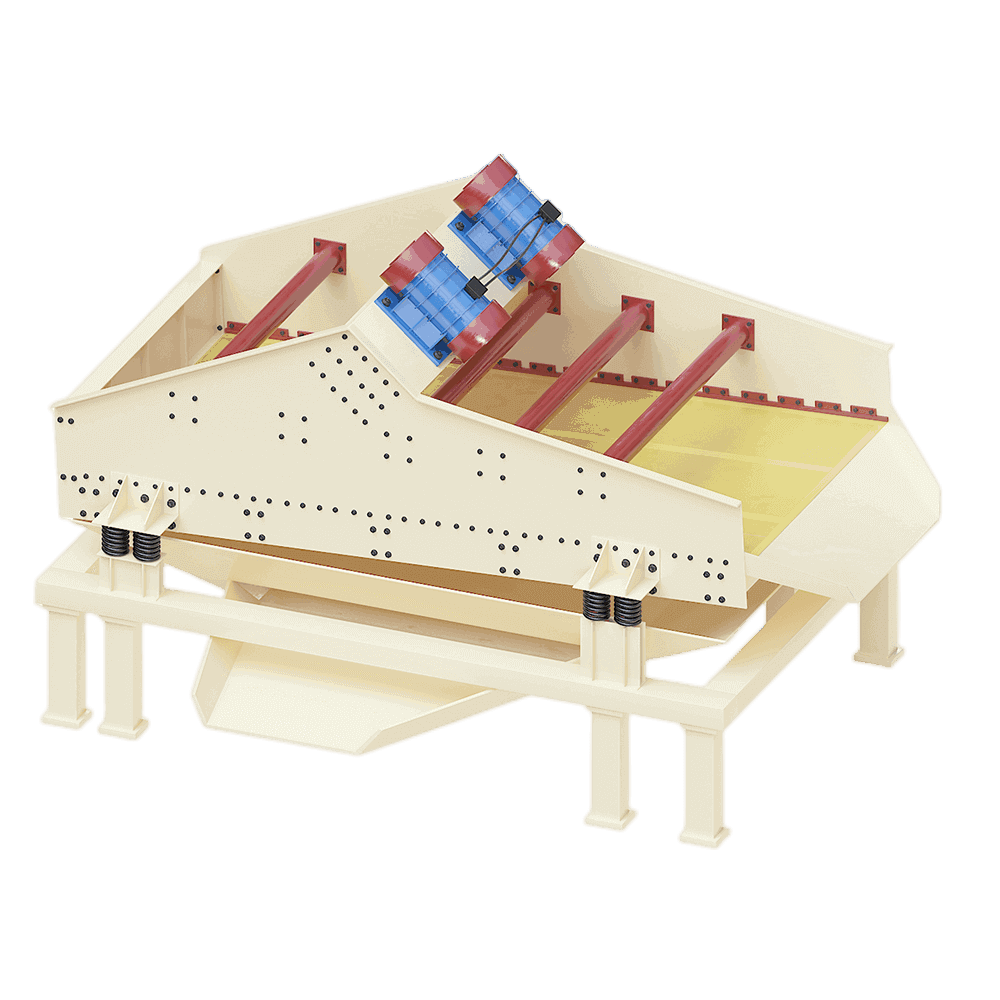

3. Diamond ore screening equipment

The vibrating screen machine is a more important part, which improves the efficiency and accuracy of mineral processing. High-frequency vibrating screens are usually used to ensure the correct screening of coarse materials while maintaining optimal throughput, allowing miners to quickly identify potential gemstones.

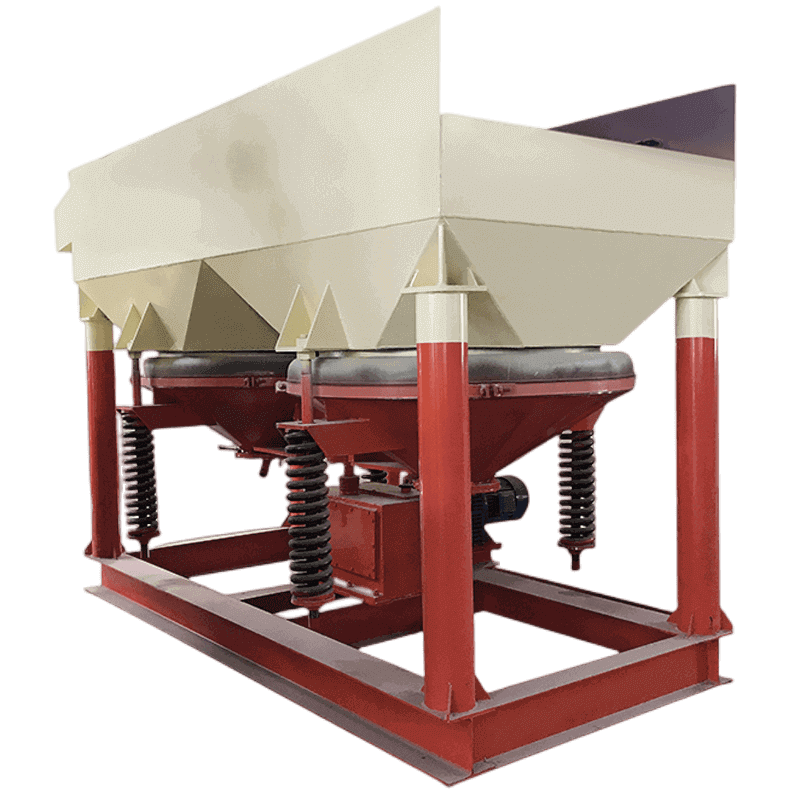

4. Diamond ore gravit separation equipment

Whether it is a placer or a primary ore, the gravity separation equipment is generally used to extract diamonds. The diamonds are sorted according to the difference in specific gravity between diamonds and waste rocks. In diamond beneficiation, the most commonly used is the jig separator, whose main function is rough selection, removing waste rocks and waste sand, and then entering the selection process. With the help of automated mechanical re-selection equipment, large-scale and efficient production can be achieved, and the beneficiation recovery efficiency is high for extremely low-content placers and primary diamond mines.

Diamond DMS Process

Another focus is the heavy medium separation process (DMS), which uses a suspended medium (such as heavy liquid or magnetic liquid) as a sorting medium. The raw ore is soaked in the suspended medium, and the diamonds and heavier impurities will settle to the bottom, while the lighter impurities float above the suspended medium. It is usually used to separate diamond ores with large density differences from other waste rocks.

An often overlooked aspect of diamond beneficiation is the water treatment system, which is usually achieved by using a dewatering screen to recycle the resources used in the processing process. If it is a small diamond mining line, we can also develop a one-stop diamond washing processing line to achieve integrated cleaning, screening, and gravity separation.

Diamond Ore Beneficiation Line

large capacity diamond wash process plant

This setup is for the alluvial diamond process plant, the size range of the materials is 0-300mm, main machines and process details as follows:

- The Hopper+vibration feeder(with grizzly bar) for sieving the size 0-130mm to the trommel scrubber, 130-300mm to the waste pile.

- The trommel scrubber is for washing the size 0-130mm, screen the size 0-25mm to the high-frequency vibration screen1#, 25-130mm to the waste pile.

- The high-frequency vibration screen1# is for sieve the size 0-0.5mm to the slurry pool, 0.5-25mm to the Hopper.

- The hopper+vibration feeder is for feeding the materials to the high-frequency vibration screen2# more smoothly.

- The high-frequency vibration screen2# is for sieving different materials size to different jig separators, making sure the high efficiency of the jig separator.

- The jig separator is for concentrating the diamond, the dewatering screen is for dewatering the products from the jig separator.

Note: The capacity for these plants can be customized as per request such as 10tph, 50tph, 100tph, etc. If the materials are not much sticky, you replace the trommel scrubber with a trommel screen, and the quantiy of the machines just for your reference, will depend on your ore information.The slurry pool and dewatering screen will depend on your need, if you want to recycle the water, these machines are needed.

Whether it is rock or alluvial diamond ore, the above washing, screening and gravity separation, and dewatering equipment can be used for diamond ore beneficiation. JXSC can customize the ore beneficiation process planning and equipment selection according to the topography of the diamond mine, the situation of the diamond mine, the properties of the diamond, the particle size of the diamond, etc. Contact us for more details!