Mining & Mineral Processing equipment

Since 1985, JXSC has been committed to providing global mines with a complete range of high-quality mining and mineral processing equipment, covering feeding, crushing, grinding, classifying, washing, screening, gravity separation, flotation, magnetic separation, etc.

Hot Sale Mining equipment

Jaw Crusher

Capacity: 1-1120t/h

Application: Primary and secondary, fine crushing of ore & rock processing.

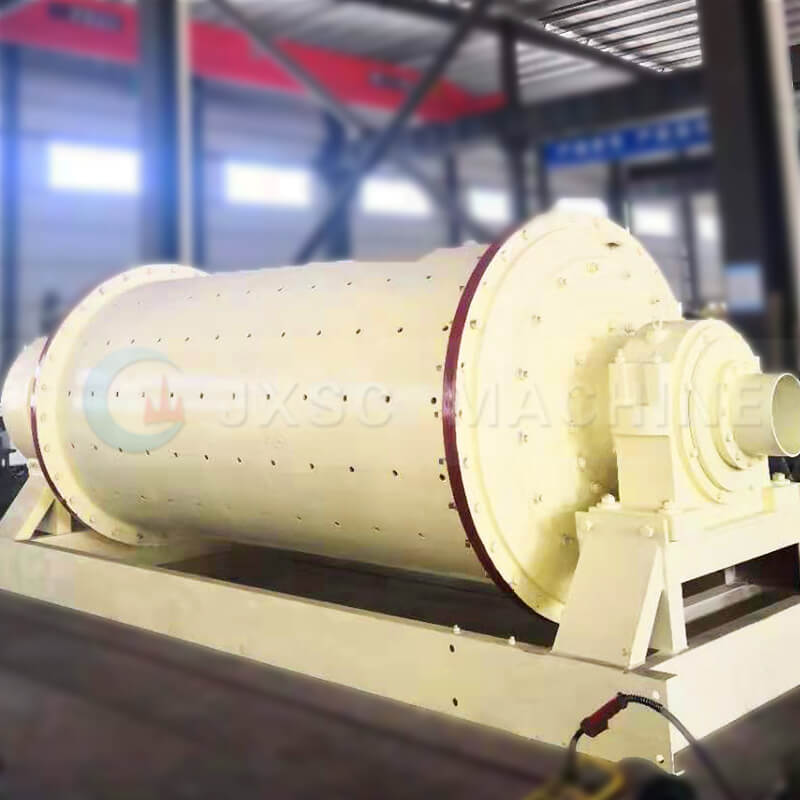

Ball Mill

Capacity: 0.4-150 T/H

Application: Dry or wet grinding of various ores: gold, lithium, copper, chrome, lead-zinc, etc.

Mobile Gold Wash Plant

Capacity: up to 300TPH

Application: small -large alluvial/placer gold, sand gold washing & recovery.

jig separator

Capacity: 1-25t/h

Application: coarse separation of gold, tin, Ta-nb, diamond, coltan, manganese, etc.

spiral chute

Capacity: 0.15-10t/h

Application: Pre-enrichment of coarse, fine heavy minerals; placer ore mining.

Magnetic Separator

wet drum type, three-disc dry type, high intensity, flat-plate type;

Iron removal and purification of non-metallic minerals.

Shaking table

Capacity: 10-20, or up to 60 t/d

Application: Fine separation of gold, tin, copper, chrome, Ta-nb, manganese, etc.

trommel scrubber

Capacity: 1-400 TPH

Application: Washing and processing of clay-rich ores to remove impurities.

flotation machine

Capacity: 0.1-50m³/min per cell

Application: Processing fine-grained copper-lead-zinc or mutli-metal ore separation.

Mineral processing Equipment For sale

JXSC is a professional mineral processing equipment manufacturer & supplier with 40+ years of experience, headquartered in Jiangxi, China. This is primarily achieved through physical or chemical methods for mineral extraction, processing, and enrichment; upgrading low-grade ore to industrial application standards. Helping customers improve concentrate grade by 15% to 35% while reducing energy consumption by 20% to 30%. Our equipment utilizes internationally advanced technology, adapted to gold, diamond, copper, manganese, tantalum-niobium, tin, lead-zinc, iron, chrome, silica sand, zircon sand, and 200+ mineral beneficiation solutions; high ROI & 95%+ recovery rate guaranteed!

Over the last few decades, JXSC has been renowned for providing intelligent, customized mineral processing equipment. All products are sold at 100% factory-direct prices, featuring durable and environmentally compliant designs, and we also offer fast shipping and installation services!

Gold mining equipment contains crushing, grinding, beneficiation, extraction, and smelting machines, which can effectively extract and process gold ore. Among them, through gravity separation, flotation, and CIP/CIL methods, efficient, safe, and environmentally friendly mineral processing equipment can achieve the maximum 90%+ gold recovery rate.

Stone crusher equipment is often used in mining, mineral processing, and construction projects. Various ores and rocks can be transformed into uniform and high-quality sand and gravel aggregates after being crushed and processed through sand making. It mainly includes jaw crusher, cone crusher, hammer crusher, impact crusher, roller crusher, sand making machine, etc.

Grinding equipment mainly includes a ball mills, wet pan mills, and Raymond mills. Among them, ball mills are widely used and are important machines for regrinding crushed materials in mineral processing plants. The wet pan mill is a piece of equipment commonly used to grind gold ore into fine powder. Classification equipment includes spiral classifiers and hydrocyclones.

Our gravity separation equipment is widely used, safe, and reliable, ensuring the mineral processing line is more environmentally friendly and improves the ore recovery rate. It mainly includes centrifugal concentrators, jigs, shaking tables, and spiral chutes.

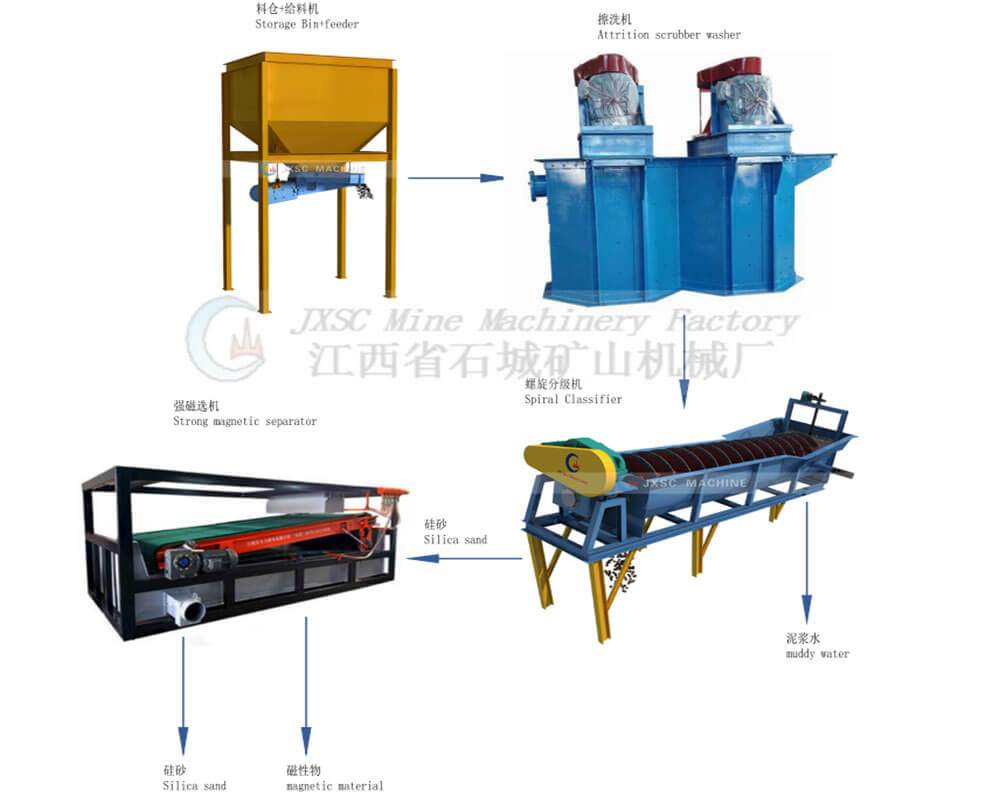

JXSC mineral separation equipment mainly includes flotation machines, magnetic separators, and electrostatic separators, with strong applicability and can achieve a maximum 90%+mineral recovery rate.

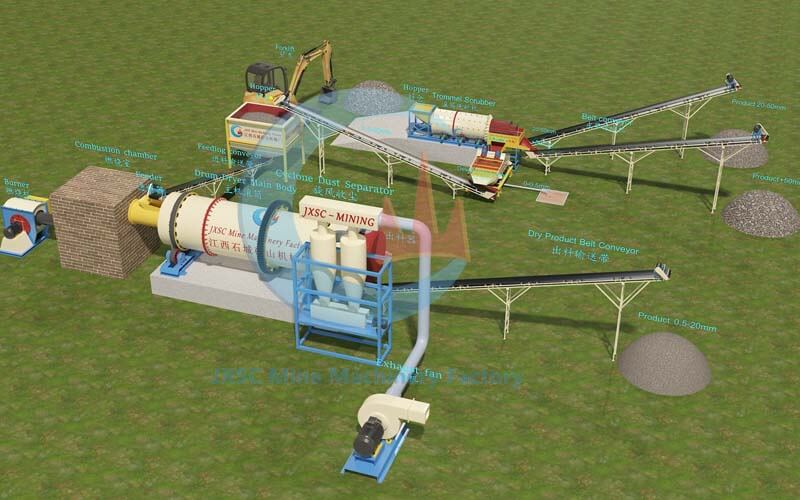

JXSC mineral washing & screening equipment includes rotary scrubbers, trommel screens, log washers, vibrating screens, spiral sand washers, fine sand recycling machines, etc. Made of wear-resistant and sturdy materials and advanced production technology, the service life is extended 3-5 times.

Efficient dewatering solutions for final concentrate processing and tailings management solutions. Advanced water recovery systems to minimize waste and environmental impact. Mainly includes dewatering screens, thickeners, plate filter press, rotary dryers, blet filter press, disc vacuum filters, etc.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.