100TPH Alluvial Gold & Columbite Processing Plant In Brazil

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project Info.

- Raw ore: Tantalum-niobium sand with a lot of mud, containing gold and columbite (niobium iron ore)

- Capacity: 100TPH

- Maximum feed size: 500 mm

- Output size: 0-2mm

- Location: Brazil

Process

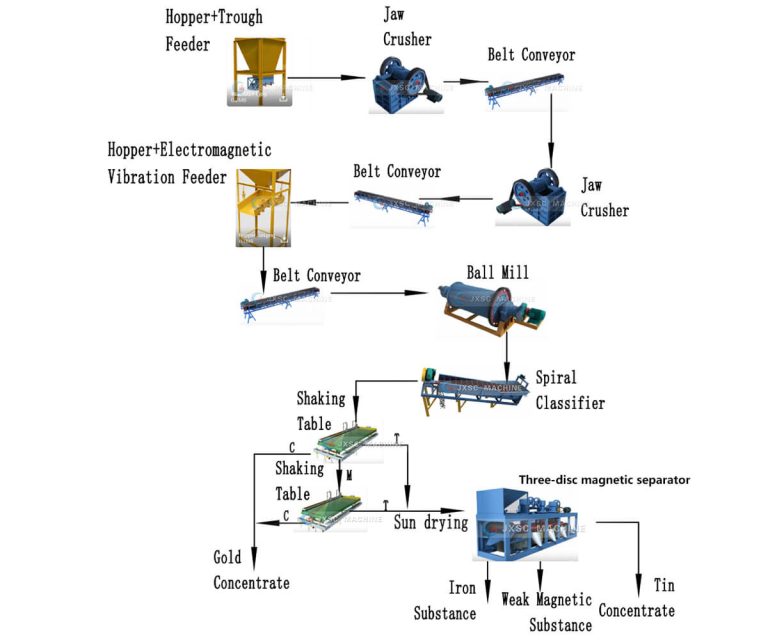

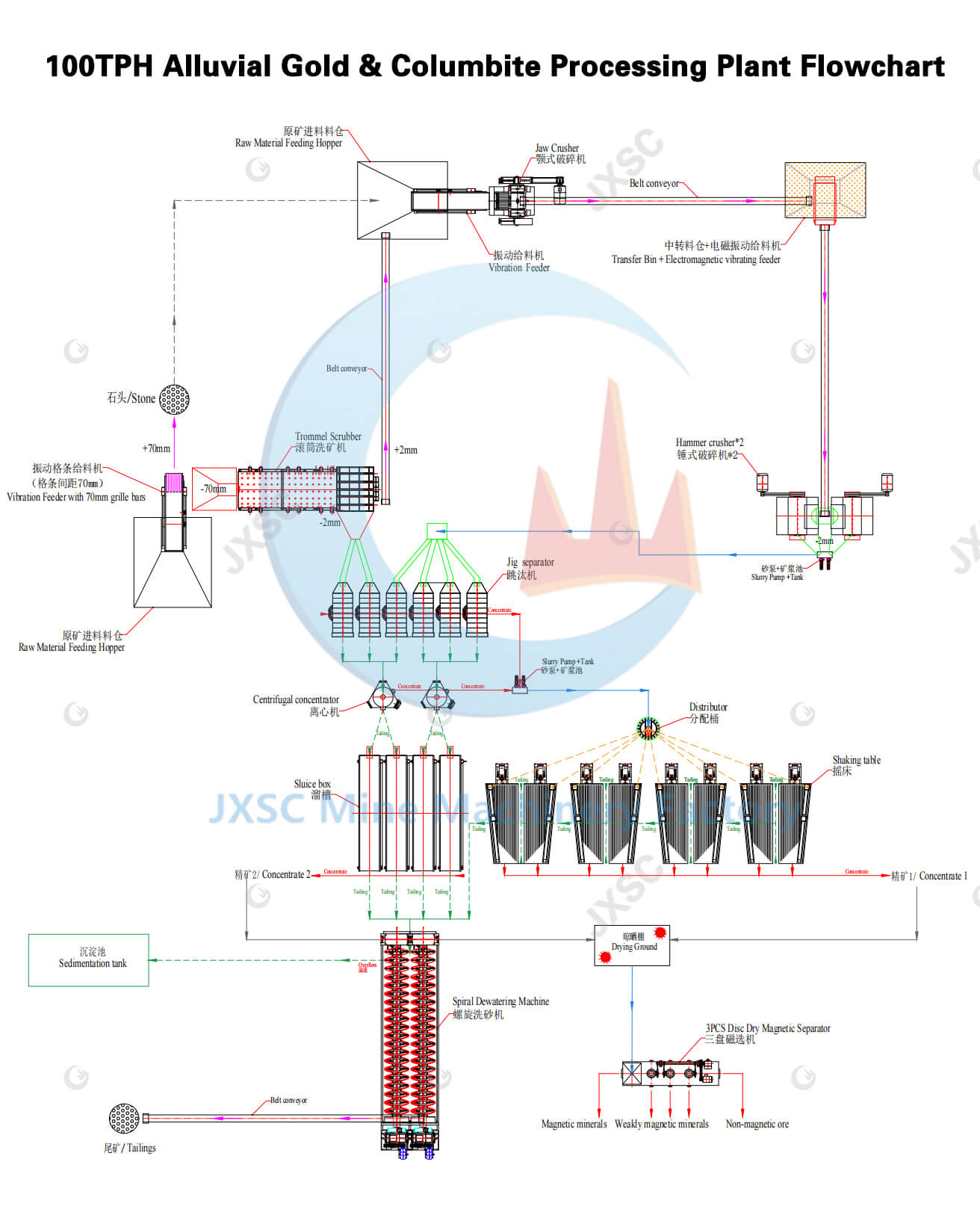

Feeding – Washing & Screening – Crushing – Gravity Separation – Dewatering – Magnetic Separation

process flow

100TPH Alluvial Gold & Columbite Processing Plant

This is a complete Brazil 100TPH gold and columbite processing plant, which is a comprehensive solution integrating multiple advanced mineral processing technologies. From the initial feeding of raw ore, to multiple key links such as crushing, screening, gravity concentration, to the final fine processing such as precipitation, dehydration and magnetic separation. The processing plant is designed to cope with the complex mineral processing needs of gold and niobium iron ore, and through the synergy of these process flows, the fine processing of raw ore and the effective extraction of high-value minerals can be achieved.

Alluvial Gold & Columbite Processing Flow

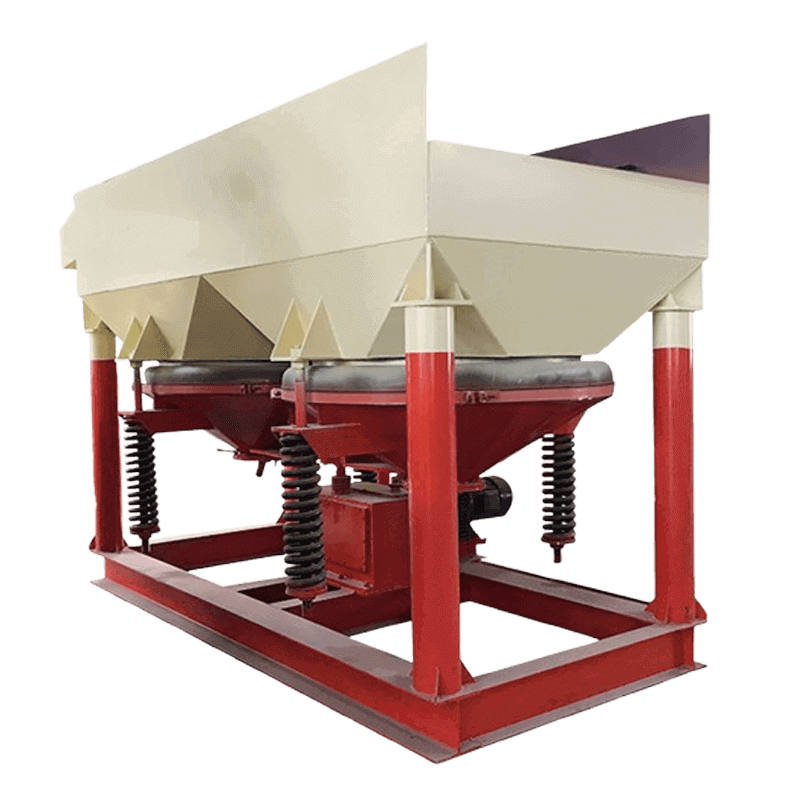

1. Feeding stage: feeding hopper, vibration feeder with 70mm grille bars

The raw ore first enters the raw ore feeding bin, which is the starting point of the entire ore dressing process. The ore passes through the vibrating feeder with 70mm grille bars, which has a grid spacing of 70mm for preliminary screening.

2. Washing and screening stage: trommel scrubber

The materials with a size less than 70mm will be washed and screened in the drum scrubber. At this time, the materials with a size greater than 2mm will be sent to the jaw crusher by the belt conveyor. The materials with a size less than 2mm will directly enter the first and second (two in total) jigging separators.

3. Crushing stage: jaw crusher and hammer crusher

- The materials larger than 70mm first enter the raw ore feed bin, and then are evenly fed to the jaw crusher through the vibrating feeder for coarse crushing, breaking the larger ore into smaller particles.

- The coarsely crushed ore enters the transfer bin and is then transported to the next stage through the electromagnetic vibrating feeder.

- The electromagnetic vibrating feeder further controls the feed amount of the ore. Then, it enters the hammer crusher through the belt conveyor for secondary crushing. The finely crushed materials are finally sent to the 3rd to 6th (a total of four) jigging separators for gravity separation.

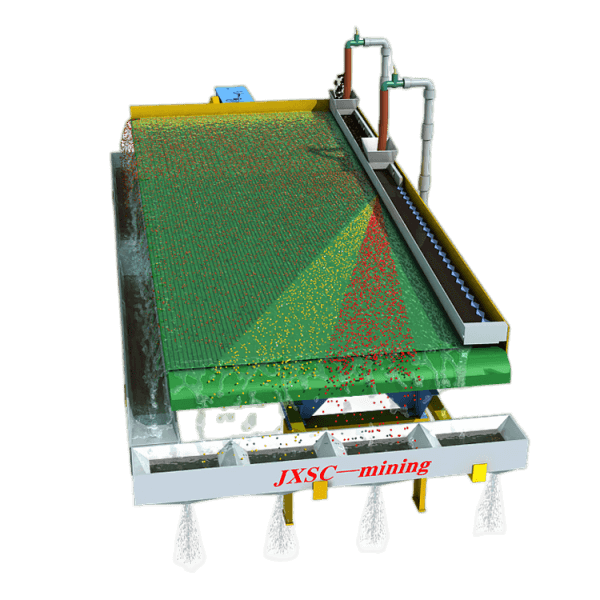

4. Gravity separation stage: jig separators, centrifugal concentrator, gold sluice box, shaking tables

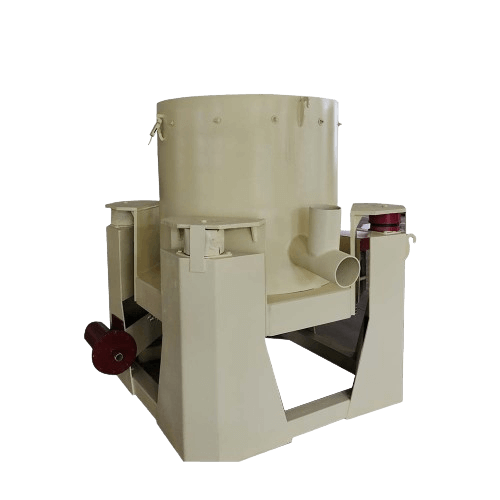

- After being processed by the drum ore washer and hammer crusher, the materials with a size less than 2 mm are all sent to the (total of 6) jig separators for rough selection. Then the tailings from the first three and last three jigs are sent to two centrifugal concentrators for further enrichment and separation.

The slurry separated by the centrifugal concentrator enters the gold sluice box to separate the concentrate 1. - At this time, all the concentrates after the jig and centrifugal concentrator enter the slurry pool through the sand pump. They are sent to the distribution bucket and then to the shaking table to separate the concentrate 2.

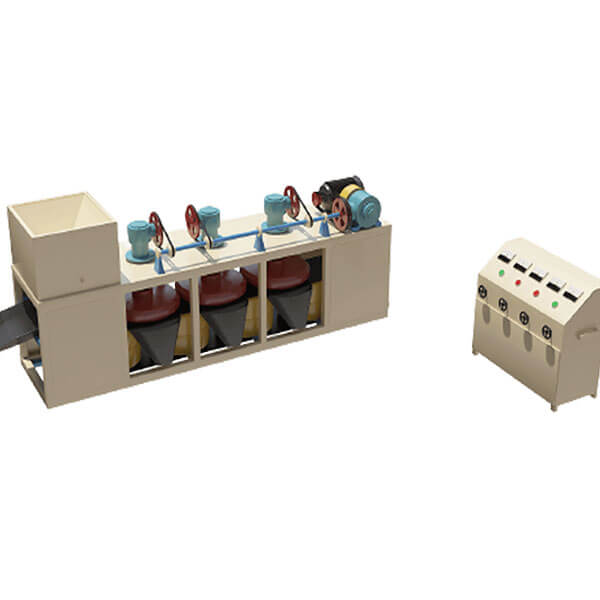

5. Drying and magnetic separation stage: spiral dewatering machine, three-disc magnetic separator

- The tailings after the gold sluice chute and shaking table are sent to the spiral sand washer for dehydration. The overflow enters the sedimentation tank to reduce pollution to the environment. The rest is transported to the tailings pile.

- Put all the materials of concentrate 1 and concentrate 2 in the drying shed for drying to obtain the final concentrate product. Then send the materials to the three-disc magnetic separator for magnetic separation to separate magnetic minerals, weakly magnetic minerals, and non-magnetic minerals (iron, niobium, gold).

The whole gold & columbite process plant gradually processes the raw ore into high-grade concentrate products through a series of crushing, screening, mineral processing, magnetic separation, and drying processes. At the same time, the tailings are treated reasonably to ensure the efficiency and environmental protection of the entire mineral processing process. Each link has a clear functional positioning and technical requirements, striving to maximize the recovery rate of minerals and the quality of concentrates. Contact us for customized complete gold, columbite (tantalum-niobium) mineral processing solutions!

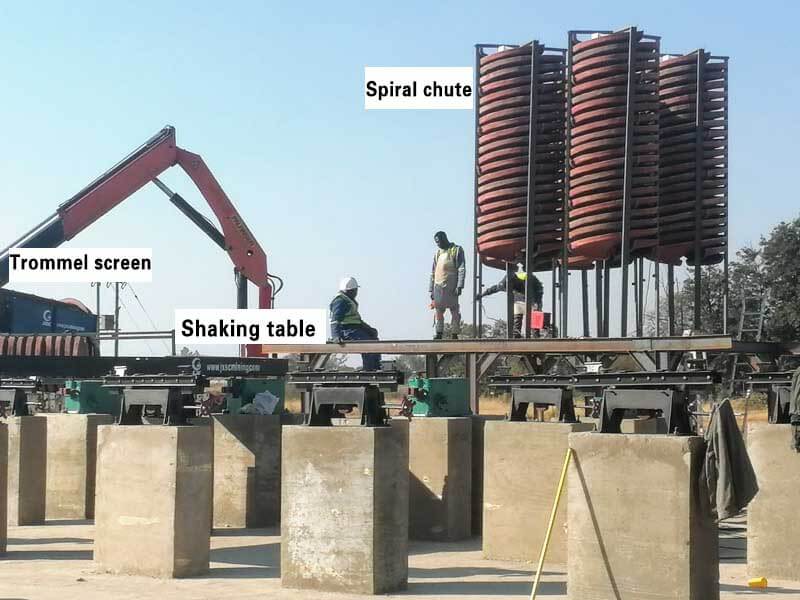

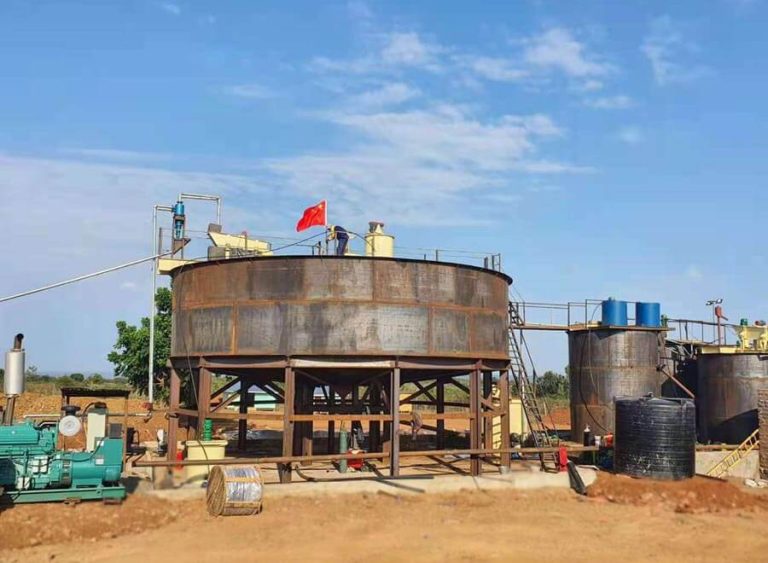

Process Site

100TPH Alluvial Gold & Columbite Processing Plant Site

Need Gold, Columbite Mineral Processing Plant Solution?

Main Equipment

100TPH Alluvial Gold & Columbite Processing Equipment list

Equipment | Parameters and Requirements | Quantity |

Vibrating Feeder | 1. Model: DN380*96 2. Processing capacity: 96 – 160 tons per hour 3. Maximum feeding size: 500 mm 4. With 70mm grid screen bars | 1 unit |

1. Model: 1500 (Drum diameter 1500mm, length of drum scrubbing part 4000mm, length of screen mesh 2000mm) 2. Processing capacity: 100 tons per hour 3. Screen mesh size: Single-layer PU screen mesh 2mm 4. Drum lining: Welded spiral blades 5. Driving mode: Tire drive Fixed type, including a receiving trough from the feeder to the scrubber | 1 unit | |

1. Model: STLB100 2. Processing capacity: 50 – 100 tons per hour 3. Feeding size: 0 – 6mm 4. Automatic ore discharge | 1 unit | |

Electromagnetic Vibrating Feeder | 1. Model: GZ4 2. Feeding size: 0 – 100mm 3. Processing capacity: 50 tons per hour 4. Motor power: 0.45kw | 1 unit |

1. Model: PE400x600 2. Processing capacity: 16 – 60 tons per hour 3. Maximum feeding size: 340mm 4. Discharge size: 40 – 100mm | 1 unit | |

1. Model: PC800x600 2. Processing capacity: 15 – 20 tons per hour 3. Maximum feeding size: 100mm 4. Discharge size: 0 – 2mm 5. 2mm grate screen mesh | 2 units | |

Old-style Large Shaking Table | 1. Bed surface size: 4500*1800mm 2. Processing capacity: 1 – 1.5 tons per hour 3. Maximum feeding size: 0 – 2mm (88 slots) | 8 units |

1. Model: 3PC – 500 2. Processing capacity: 100 – 500kg per hour 3. Feeding size: 0 – 2mm 4. Gauss: 18000 – 20000 | 1 unit |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.