100TPH Diamond Washing Screening Plant In South Africa

We guarantee the high quality machine in the mineral processing industry, established in 39+ years of experience!

Project Info.

- Materials: alluvial diamond with clay

- Capacity: 100TPH

- Feed size: >100mm

- Output size: 2-10mm, 10-25mm

- Location: South Africa

Process

Feeding- Washing – Screening

process flow

100TPH Diamond Washing Screening Plant flow

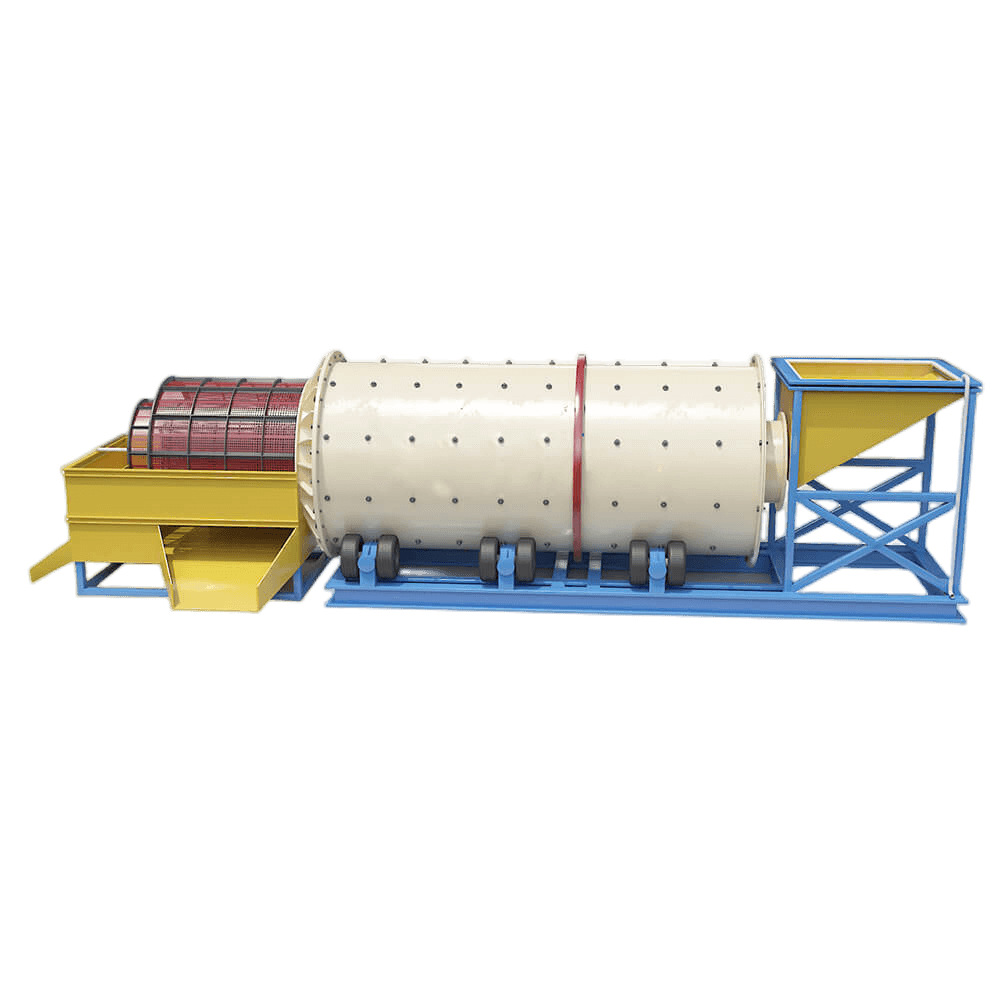

JXSC designed a complete 100 t/h diamond washing & screening plant for a South African customer, ores with cohesive clays. Therefore, the plant’s main equipment includes vibrating feeders, trommel scrubbers, high-frequency vibrating screens, and belt conveyors.

- The raw materials can be fed into the feeding hopper through a dump truck or wheel loader, and then a vibrating feeder is used to feed the raw materials smoothly into the trommel scrubber. The vibrating feeder has a grizzly bar with a 40mm gap to remove waste above 40mm, and 0-40mm enters the trommel scrubber through gravity flow.

- The 0-40mm slurry material from the vibrating feeder will flow into the trommel scrubber to clean the raw materials. There is a 25mm size screen at the end of the trommel scrubber, which separates and sends away materials exceeding 25mm. Among them, above 25mm waste materials can be transported to the stockyard by conveyor.

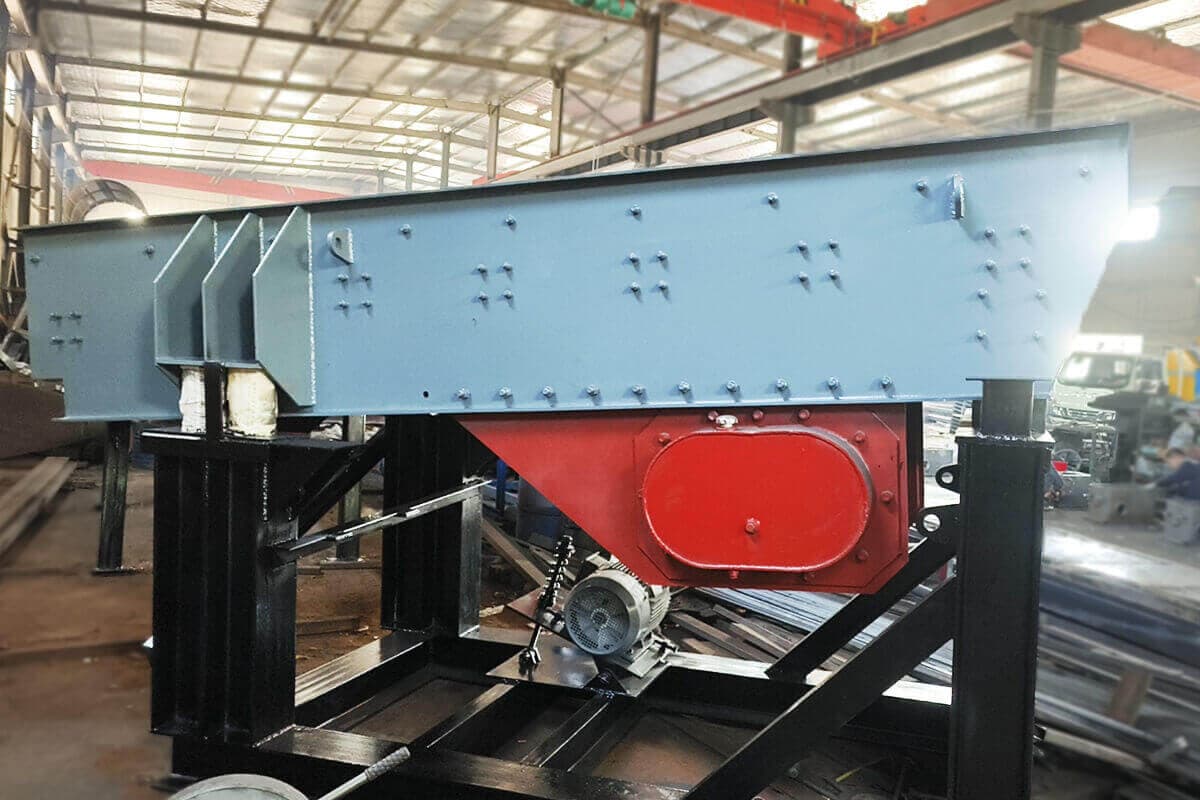

- The 0-25mm slurry will enter the next machine – high-frequency vibrating screen, for further washing and screening. The screening machine has two layers of screen mesh: 2mm and 10mm. The machine is equipped with a water spray pipe to clean the materials again and remove 0-2mm mud and water. Among them, the tailings of materials smaller than 2mm are sent to the sedimentation tank. Materials of 2-10mm and 10-25mm are transported to the corresponding piles for collection.

Note: If the material is not very sticky, the drum scrubber can be replaced with a screen. If the diamond concentrate needs to be concentrated, jig separators can be added later. Machine quantity is for reference only and depends on your production capacity. The factory’s production capacity can be customized according to requirements, such as 10tph, 50tph, 200tph, etc.

JXSC will customize full diamond processing plants based on your details or situation. Our professional and experienced overseas engineers team will confirm all the details with you. Contact us to get affordable prices!

Main Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.