50-80TPH Alluvial Diamond Washing Processing In Angola

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience.

Project Info

Materials: Alluvial diamond ore, containing a large amount of sticky clay, gravel and some large stones

Capacity: 50-80TPH (50-80 tons/hour)

Feed size: >75mm

Diamond concentrate size: 2-25mm

Location: Angola

Process

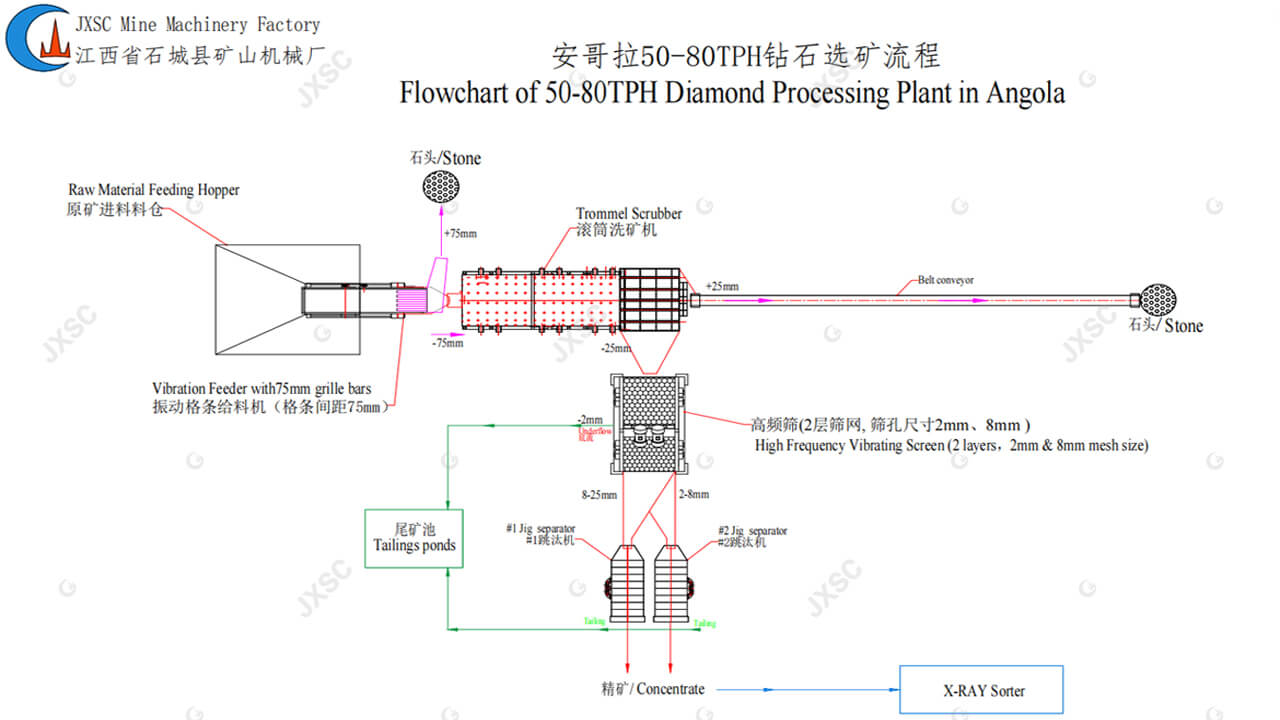

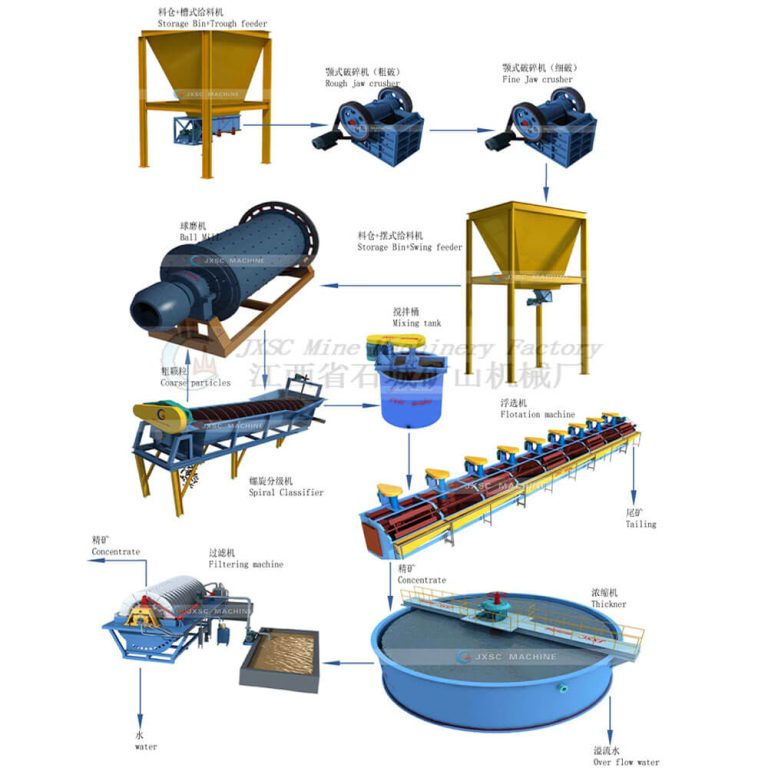

Feeding – Washing – Screening – Jig gravity separation

process flow

50-80TPH Diamond Washing Processing flow

The customer’s requirement is to clean the raw ore, remove waste stones, and then sort the diamonds in a centralized manner; with our own engineers, we mainly provide detailed factory layout drawings and each machine drawing to help with installation. Based on Angola’s customer requirements and ore conditions, JXSC designed and provided a complete set of impact diamond washing and processing plant machines and all accessories, with a processing capacity of 50-80TPH.

The main equipment includes vibrating feeder + trommel scrubber + belt conveyor + high-frequency vibrating screen + jig separators + water pump. The specific details are as follows:

1. Customers can use wheel loaders or excavators to feed raw ore into the vibrating feeder (with a 75mm gap), which can remove +75mm of waste rock to the ground. Water needs to be sprayed on the vibrating feeder so that materials of 0-75mm can enter the drum washer more smoothly. While removing oversized stones, the raw ore is evenly fed into the drum washing machine.

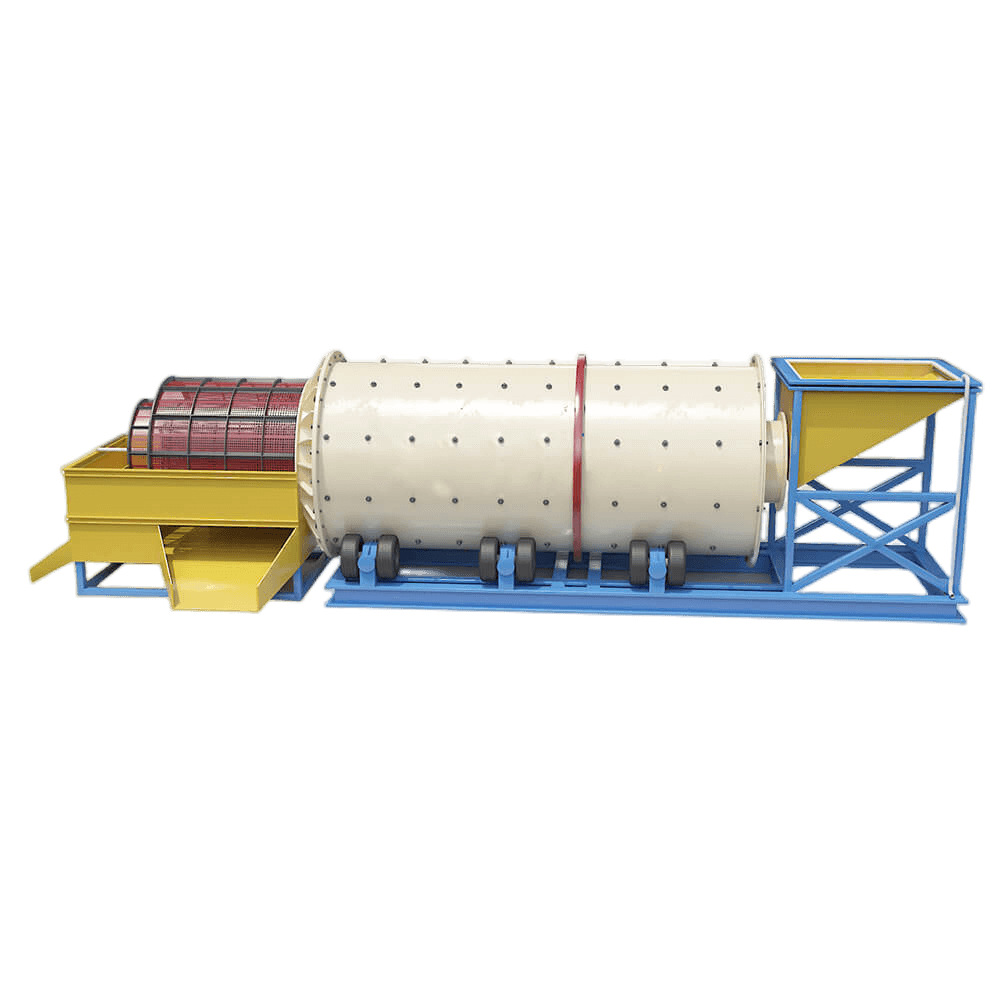

2. The 0-75mm material enters the trommel scrubber for washing, and the screen size is 25mm to release diamonds from the clay. After cleaning, +25mm waste gravel will be screened out, and the discharged 0-25mm material will flow to the high-frequency vibrating screen.

3. The high-frequency vibrating screen uses 2mm & 8mm PU screen mesh, and high-pressure water is sprayed on the screen mesh; this can clean 2-25mm more cleanly and remove 0-2mm muddy water at the same time. Then, materials in two size ranges of 2-8mm and 8-25mm are obtained and fed into two different jig separators.

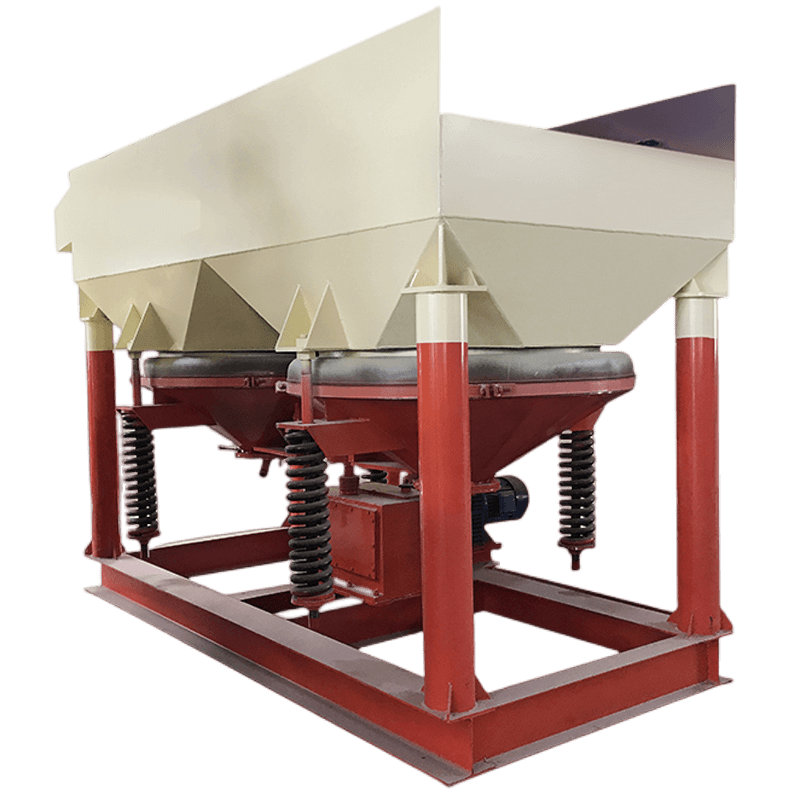

4. The jig separators are used to select diamonds. The 2-8mm and 8-25mm materials will be fed into two jigs respectively, so the concentration effect will be better. Diamond concentrate is obtained from the jig.

Note: If you require a higher purity diamond, individual diamonds can be sorted by hand or with an X-ray sorter. JXSC supports customizing complete sets of diamond processing solutions (alluvial/ Kimberlite/ rock ore) and mining equipment to achieve high recovery rates. Contact us to get a quote!

Main Equipment

|

No. |

Machinery List |

Model No. |

Quantity (Set) |

|

1 |

Vibration feeder |

3800*960 |

1 |

|

2 |

Trommel scrubber |

JXSC-1200 |

1 |

|

3 |

Belt conveyor |

650*15M |

1 |

|

4 |

High frequency vibration screen |

JXSC-1545-2 |

1 |

|

5 |

Jig separator |

JT4-2 |

2 |

|

6 |

#1Water pump |

8inch |

1 |

|

7 |

#2Water pump |

6inch |

1 |

|

8 |

#3Water pump |

4inch |

3 |

|

9 |

Full set water pipes |

/ |

1 |

|

10 |

Full set electric control pannel |

/ |

1 |

|

11 |

Full set cables |

/ |

1 |

|

12 |

Full set steel material for making connection chutes & hopper |

/ |

1 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.