5TPH Alluvial Gold Washing Plant In Mozambique

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience.

Project Info

1. Materials: alluvial gold with contain clay

2. Capacity: 5TPH (5 tons per hour)

3. Feed size: >100mm

4. Location: Mozambique

Process

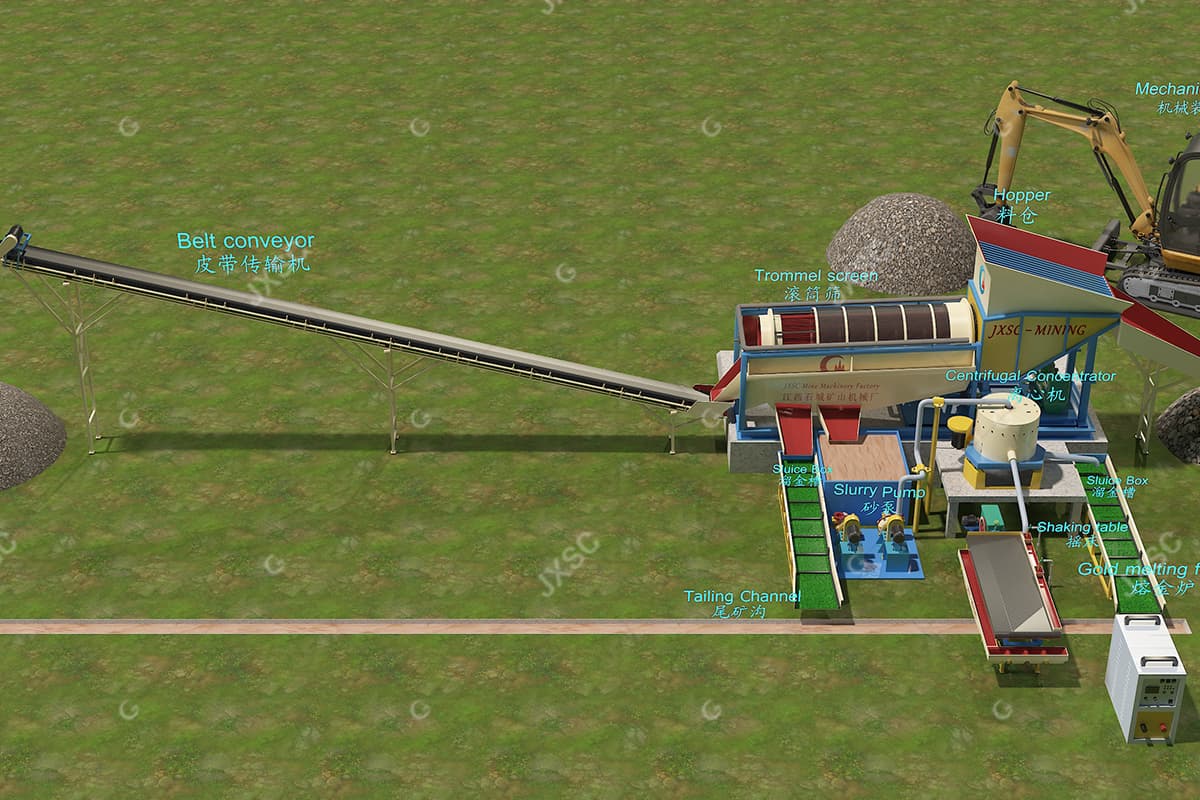

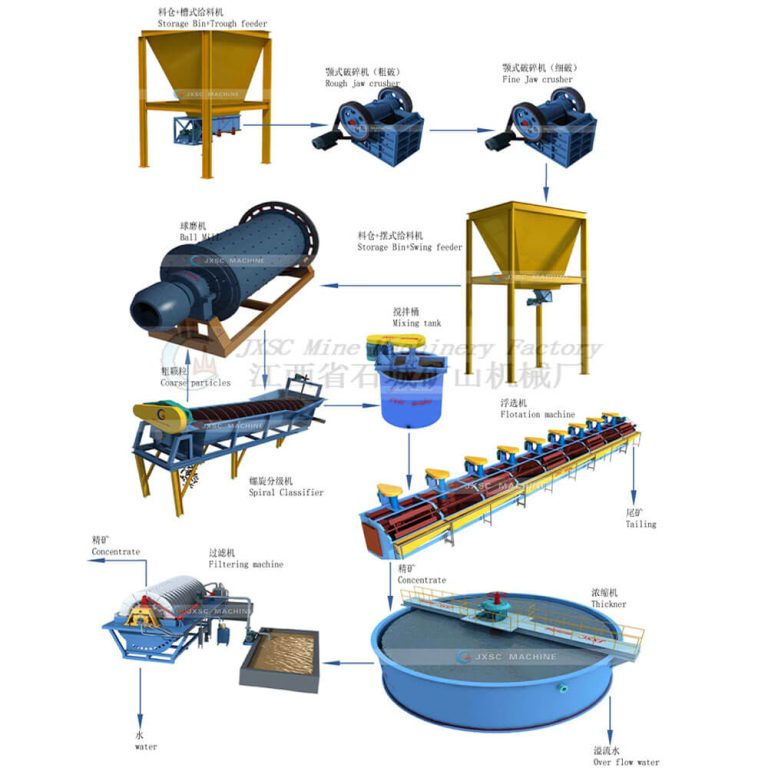

Washing – Screening – Gravity Separation(centrifugal concentrator – sluice box – shaking table) – Melting furnace

process flow

5TPH Alluvial Gold Washing Plant flow

The client had a limited budget and not much gold content. The customer requires that impurities on the surface of the ore be washed first and then sorted; however, the final concentrate recovery rate should be as high as 95% or more. JXSC has developed a complete set of alluvial gold washing plants according to the requirements. The following is the specific process flow:

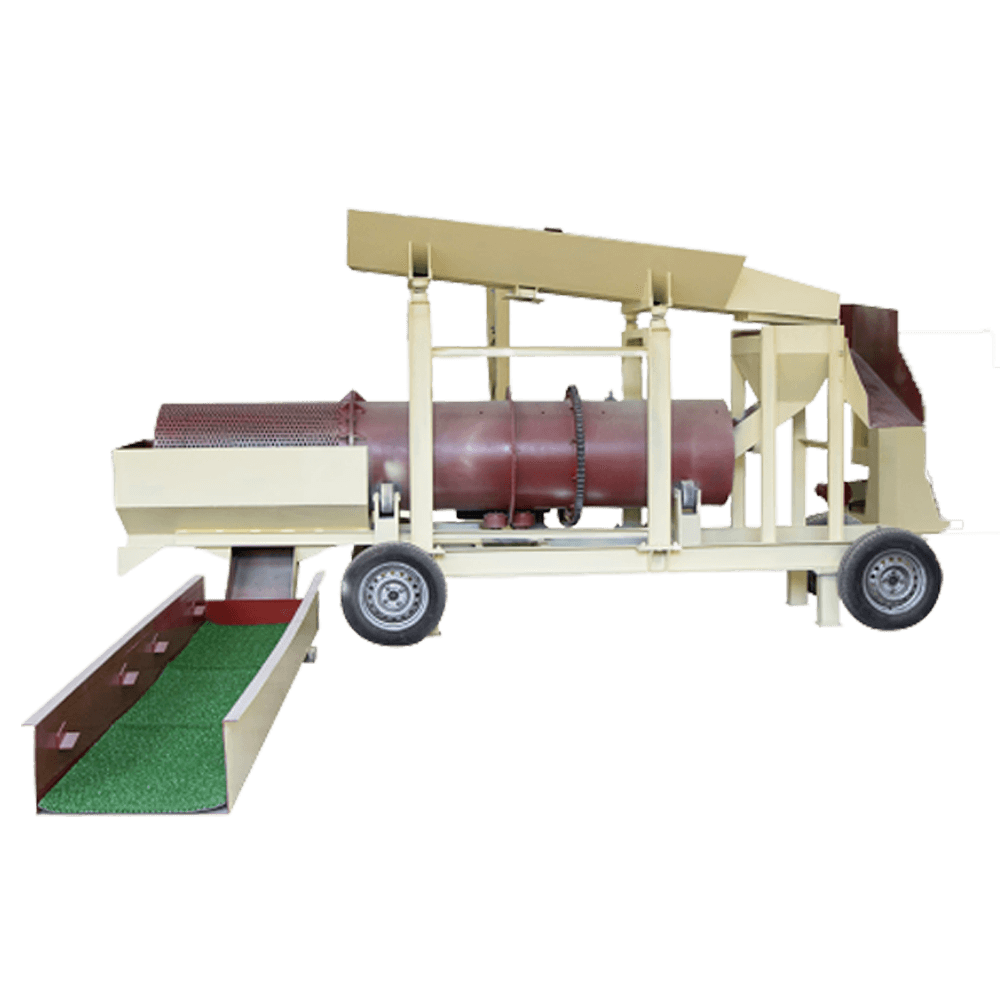

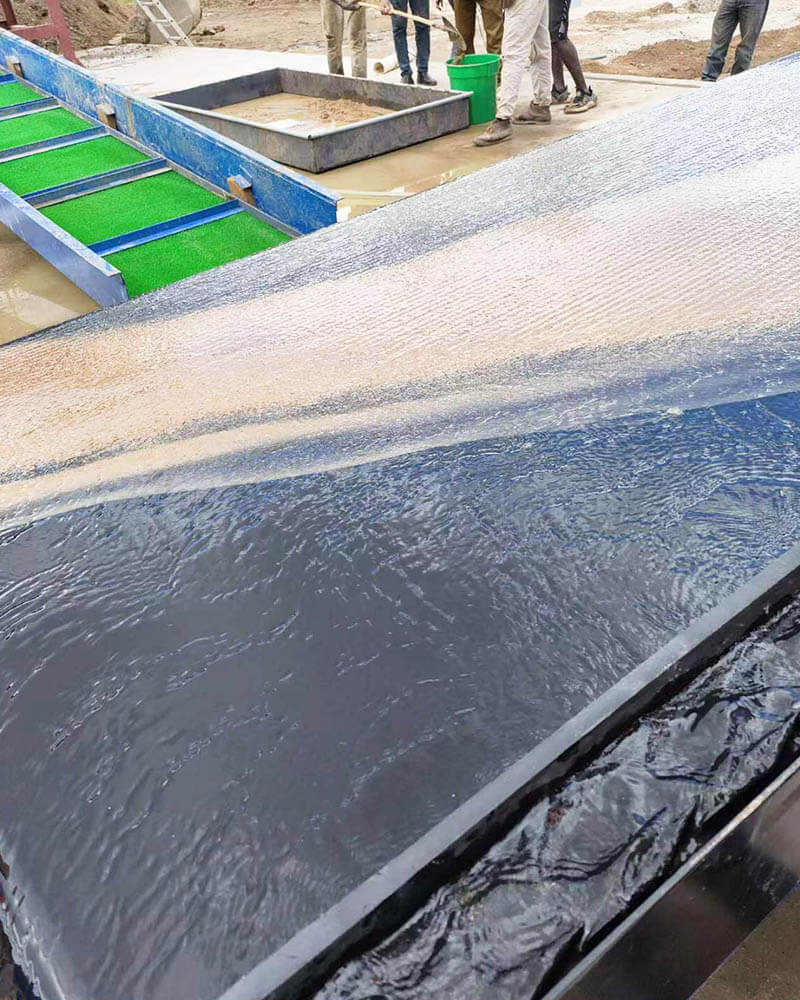

- The trommel screen is designed with moving wheels, making it easy to move. It can also be made into a fixed type upon request. First, we use a loader to feed the raw materials into the trommel screen, and we make two layers of screens, 6mm and 20mm respectively. Materials above 20mm after screening are transported by belt conveyor as waste sand. Then the 6-20mm material is input into the gold sluice box according to the height difference to capture the gold particles. This is the first part where we can get gold coins.

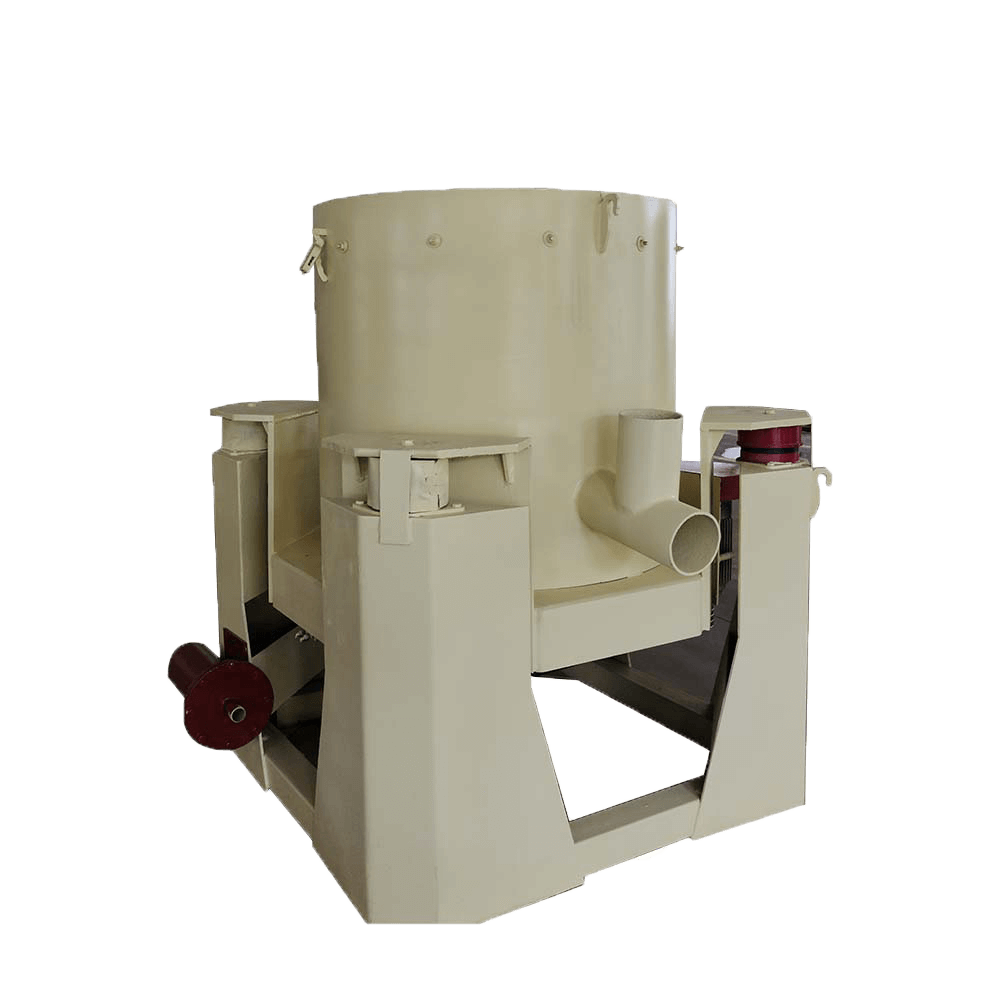

- Next, we use a slurry pump to pump the last 6mm of material below to the centrifugal concentrator. The centrifugal concentrator can concentrate gold particles of 0-6mm.

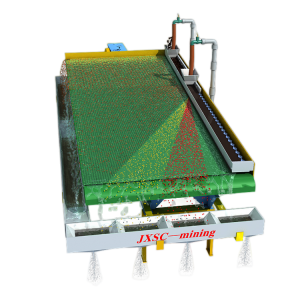

- Then its slurry enters the shaker through the pipeline, and the shaking table can concentrate the gold powder between 0-2mm. Since the concentrate also contains a small amount of sand, using a shaker can effectively separate the sand from the gold. Finally, the finished product is smelted into gold bars in a gold melting furnace.

Trommel screens, centrifugal concentrators, and shakers can be replaced with different models and increased in quantity according to different production capacities. The gold sluice box can be designed in different lengths and widths, such as 2m, 4m, 6m long, 1m wide, and 0.5m wide. The gold washing plant is ideally suited for the recovery of alluvial gold ore that does not contain sticky clay. If the raw ore contains a large amount of sticky clay, we recommend using a trommel scrubber, which has strong cleaning capabilities. The capacity of the washing plant can be customized according to requirements, such as 10tph, 50tph, 100tph, etc. Contact us to get factory affordable prices!

Main Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.