5TPH Rock Gold Gravity Separation Process Plant In Zambia

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project Info.

- Raw ore: rock gold mineral

- Capacity: 5TPH

- Maximum feed size: 300mm

- Output: gold bar

- Location: Zambia

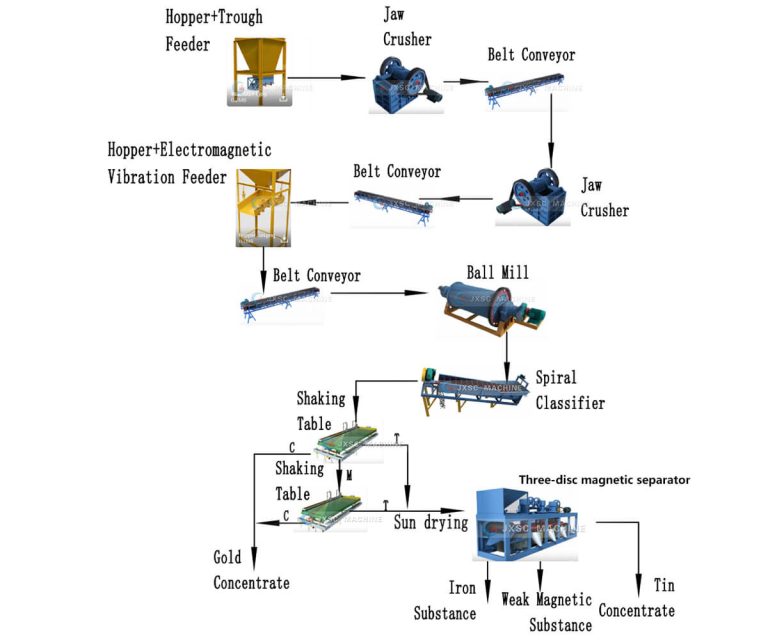

Process

Two-stage crushing – gravity separation (centrifugal concentrator, shaking table, sluice box) – Melting

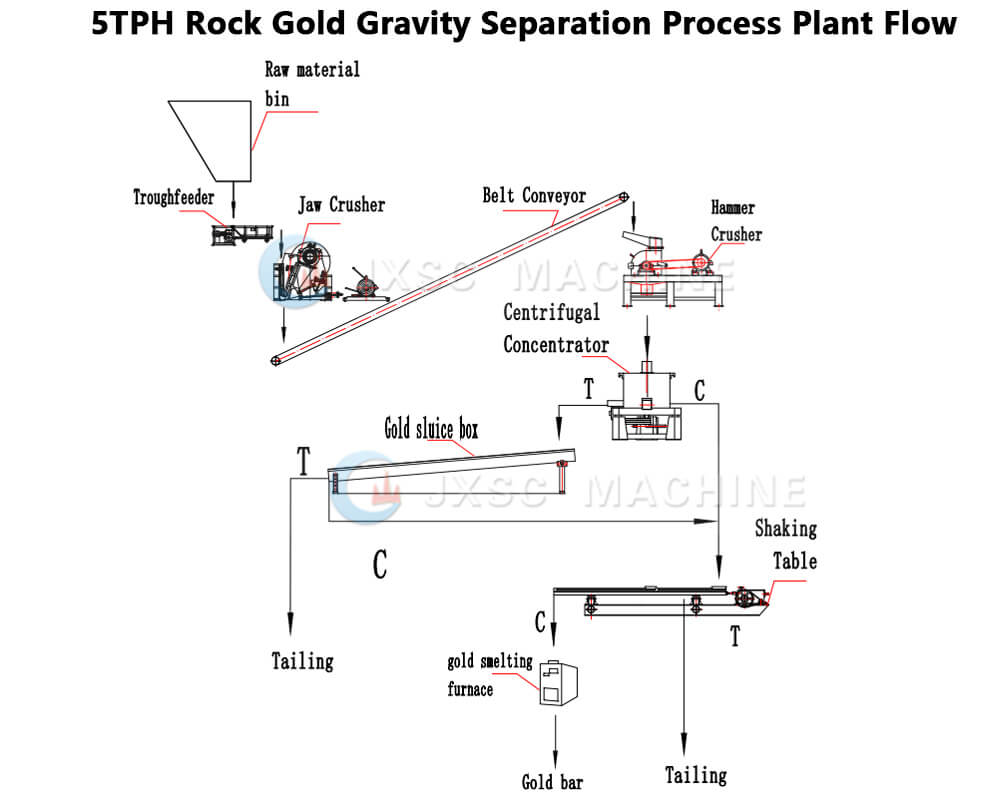

process flow

5TPH Rock Gold Gravity Separation Process Plant

The 5TPH rock gold gravity separation process plant adopts a two-stage crushing + gravity separation process, combining the high efficiency and low pollution characteristics of gravity separation to achieve the enrichment and purification of rock gold. The process is mainly divided into the following stages:

5TPH Rock Gold Gravity Separation Process Flow

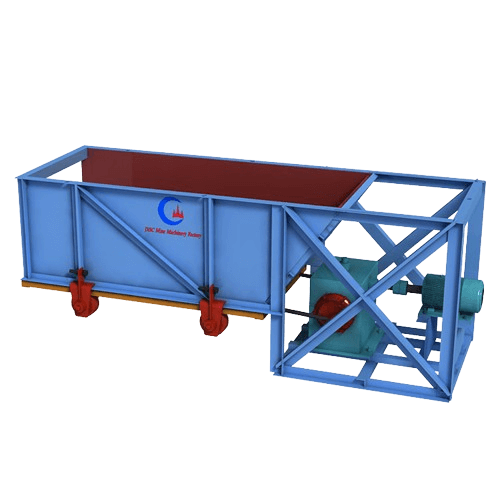

1. Raw Material Storage and Feeding

Equipment: Raw Material Bin + Trough Feeder

Raw ore (rock gold ore) is temporarily stored in the raw material bin and evenly transported to the crushing system via the trough feeder, ensuring continuous and stable operation of subsequent equipment.

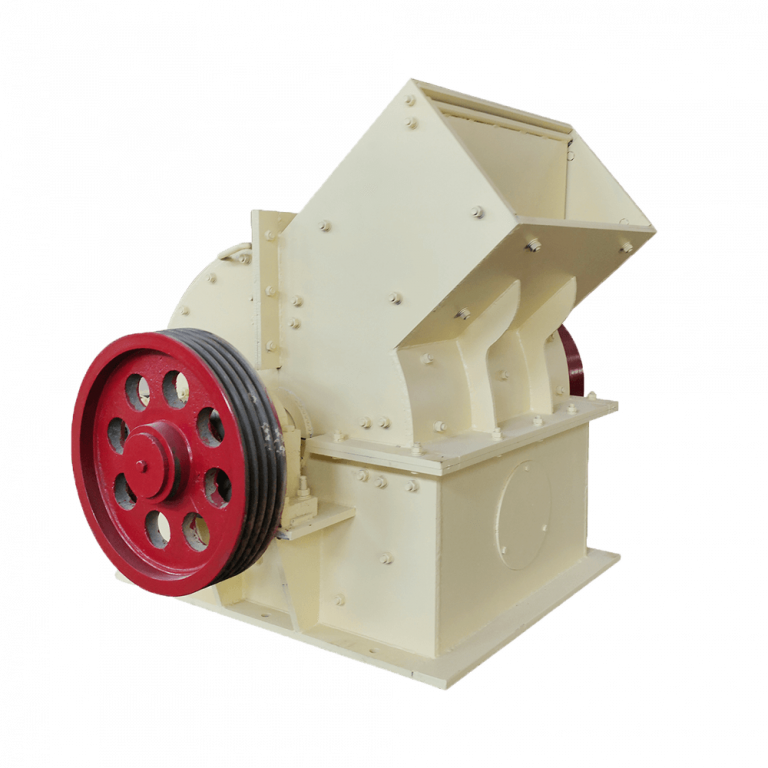

2. Crushing Stage

Equipment: Jaw Crusher, Hammer Crusher

- The jaw crusher performs coarse crushing of large ore, reducing larger particles to medium-sized particles (typically ≤100mm) in preparation for subsequent fine crushing. It has a high processing capacity and is suitable for high-hardness ores (such as quartz vein gold deposits).

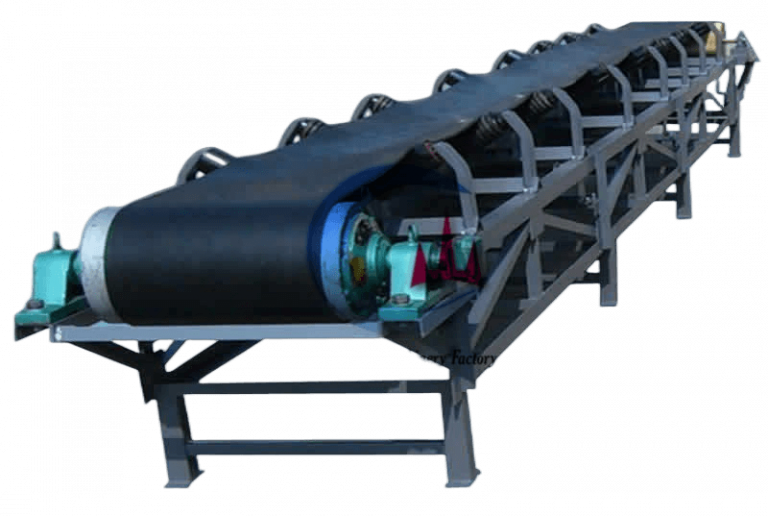

- The hammer crusher uses high-speed rotating hammers to further crush the coarsely crushed ore to a fine particle size of -5mm (fine), fully separating the gold minerals from the gangue. The crushed ore is then transported to the gravity separation system via a belt conveyor.

3. Gravity Concentration Stage

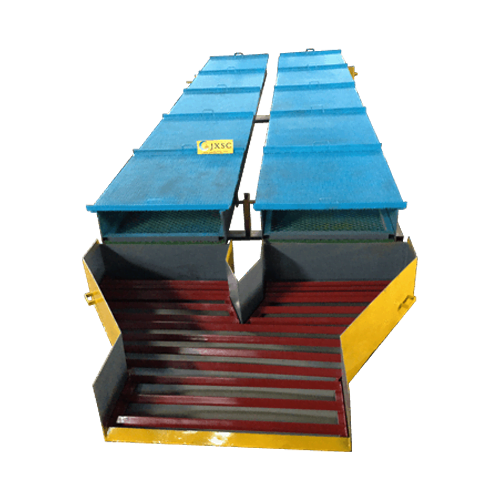

Equipment: Centrifugal Concentrator, Shaking Table, Gold Sluice Box

- The centrifugal concentrator uses enhanced gravity separation to rapidly concentrate fine gold (especially individual gold) from the slurry, producing high-grade concentrate (C) and tailings (T). This provides high recovery rates for fine gold particles, high throughput, and continuous operation.

- The shaking table performs secondary separation on the tailings (T) from the centrifugal concentrator, improving overall recovery. Sorting accuracy is high, and product grade can be controlled by adjusting the bed inclination and stroke.

- The combined action of the sluice box water flow and baffles (grids) intercepts coarse gold particles, reducing the load on subsequent equipment.

4. Concentrate Purification and Melting

Equipment: Gold Smelting Furnace

The high-grade concentrate (C) produced by the centrifugal concentrator and shaking table is fed into the gold smelting furnace. High-temperature smelting (with the addition of flux to remove impurities) ultimately produces gold bars with a purity of ≥99.5%. According to demand, the tailings after gravity separation can be dehydrated and then stored or further comprehensively utilized, without chemical pollution, in line with environmental protection requirements.

This 5TPH rock gold gravity separation plant utilizes a streamlined process of “two-stage crushing – centrifugation + shaker gravity separation – smelting and purification” to efficiently utilize low-grade rock gold ore. Its core advantages lie in the environmentally friendly, high recovery rate, and low cost of gravity separation technology. It is also suitable for the beneficiation needs of small and medium-sized rock gold mines in African countries such as Zimbabwe, Ghana, Kenya, and Congo. Contact JXSC for a customized complete gold processing solution and equipment tailored to your ore profile (placer gold, rock gold, sulfide ore) and needs.

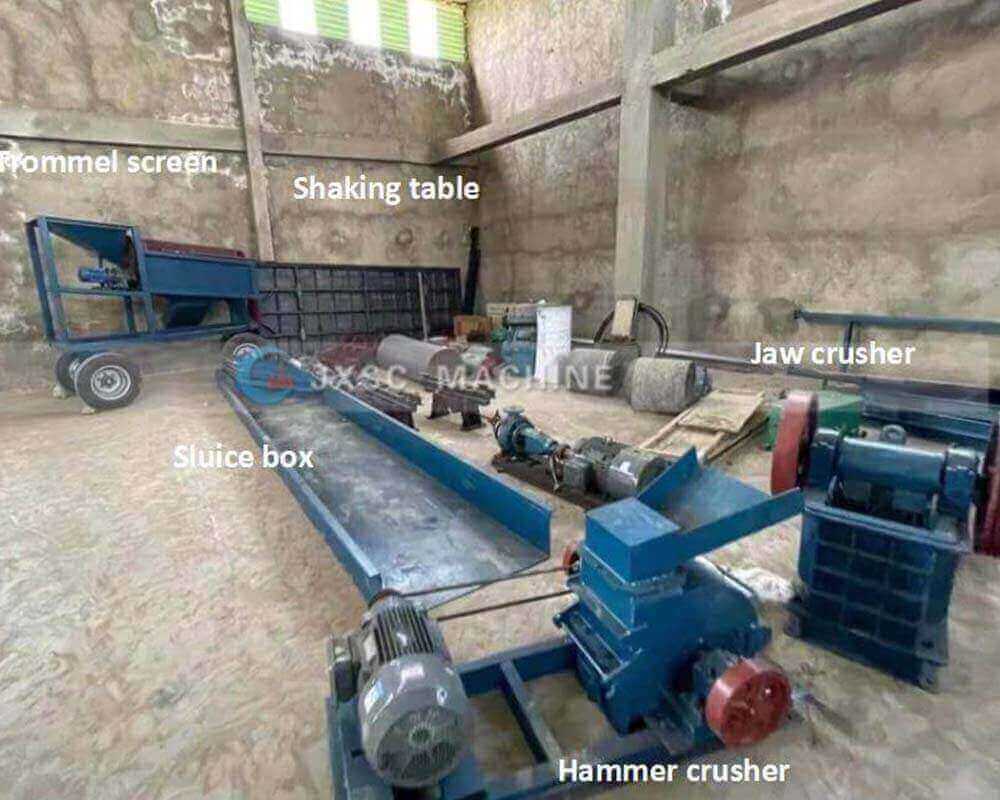

Process Site

5TPH Rock Gold Gravity Separation Process Solution

Advantages Of The 5TPH Rock Gold Gravity Separation Process

√ Efficient Gold Recovery: Combining a centrifugal concentrator (for fine gold) with a shaker (for medium-coarse gold), this process covers gold recovery for various particle sizes, achieving an overall recovery rate of 85%-92%. This process is suitable for both oxidized and primary ores, and is particularly well-suited for the quartz vein-type gold deposits common in Zambia.

√ Low Cost: The gravity separation equipment requires only water and power, offering a simple structure and low maintenance, making it suitable for small and medium-sized mines.

√ Environmentally Friendly: The entire process produces no toxic chemical emissions, and tailings can be directly dry-stacked or backfilled, complying with Zambian environmental regulations.

√ Safe Operation: The physical separation process is stable, operationally simple, and requires minimal manual intervention.

√ Flexible and Scalable: The crushing size can be adjusted based on ore properties (e.g., by adding a ball mill for fine separation) or by adding equipment such as a jig. Later, it can be upgraded to a combined gravity separation + flotation process to further improve recovery rates for complex ores.

Main Equipment

| No. | Equipment | Parameter requirements | Quantity(set) |

| 1 | Trough feeder |

| 1 |

| 2 | Jaw crusher |

| 1 |

| 3 | Belt conveyor |

| 1 |

| 4 | Hammer crusher |

| 1 |

| 5 | Centrifugal concentrator |

| 1 |

| 6 | Sluice box |

| 1 |

| 7 | Shaking table |

| 1 |

| 8 | Water pump |

| 1 |

| 9 | Water pump |

| 1 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.