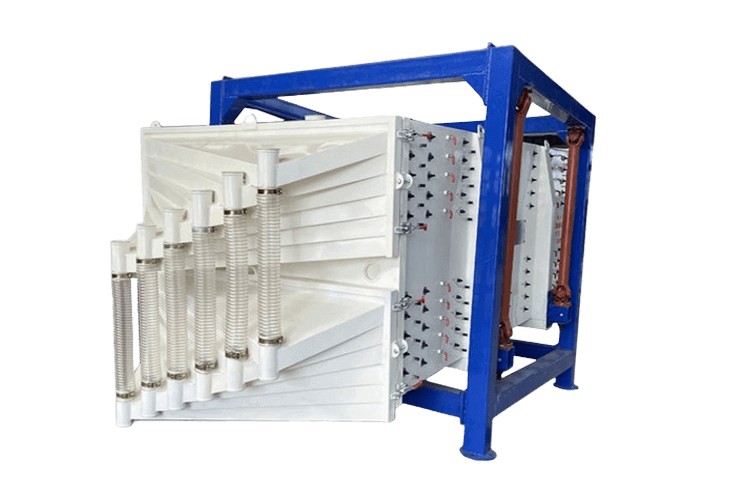

Attrition Scrubbing Machine

Volume: 1-12 m³

Feeding Size: ≤5mm

Capacity: 0-80t/h

Application: Attrition scrubbing machine is widely used for scrubbing silica sand, quartz sand, potassium albite feldspar ore, natural silica sand, glass sand, beach sand, construction silica sand; ore slime, and removal of impurities on the surface of minerals.

Products display

Introduction of attrition scrubbing machine

An attrition scrubbing machine/scrubber or agitator washer, is mainly used for the dispersion of ore slime, removal and scrubbing of impurities on the mineral surface in the production process of silica sand (quartz sand) or potassium feldspar. It is a mechanical equipment specially used for cleaning and scrubbing high-purity abrasive materials such as silica sand and quartz sand. It is also called “quartz/ silica sand attrition scrubber“- a key equipment used for washing and purification in quartz sand beneficiation.

The material feed particle size is usually ≤5mm, and the mud content is high (such as 10%-30%), which requires hydraulic scrubbing to remove mud. Using an attrition scrubber to remove clay, organic matter, and other impurities on the surface of sand, the purity and industrial application value of sand can be improved.

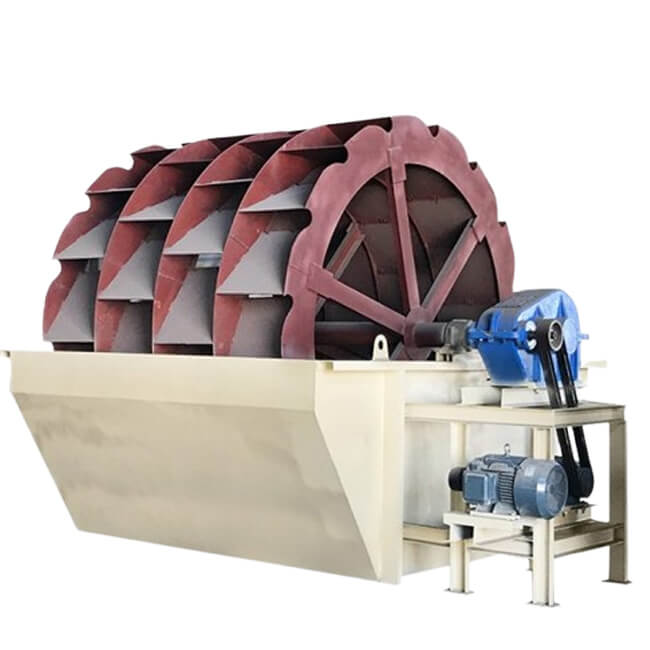

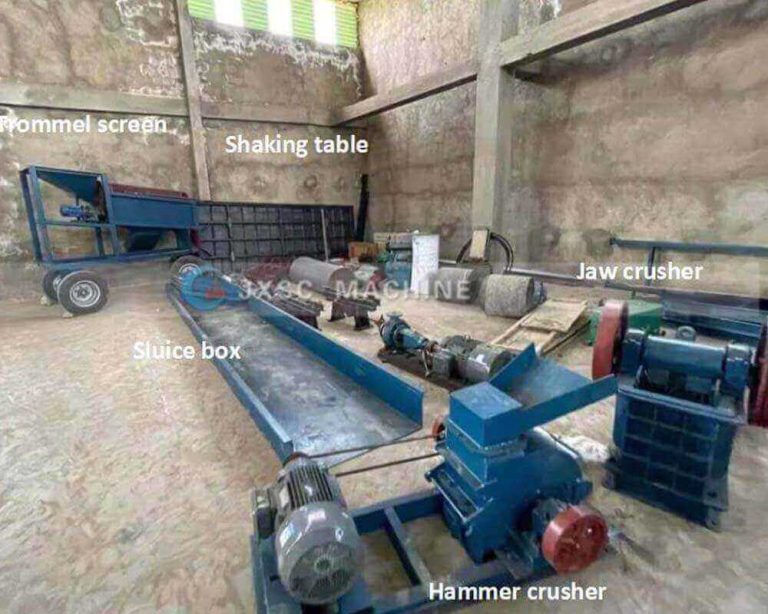

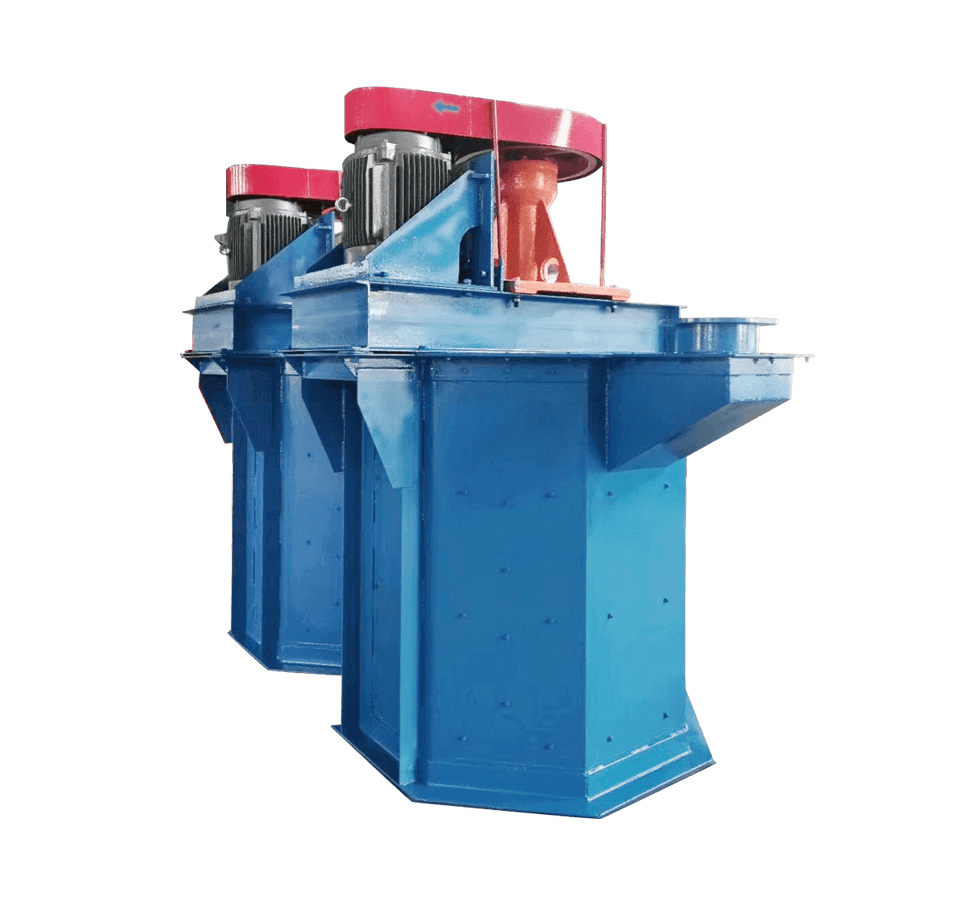

The attrition scrubber is generally used before or after the spiral sand washer in the sand washing plant to scrub the particle surface and decompose impurities. It can also scrub hard ores and aggregates in sand production lines requiring higher quality. The scrubbing machine cleaning process involves strong stirring, and the scrubbed material can increase the recovery rate of mineral processing. According to the specific process requirements, it can be matched with a vibrating screen, spiral classifier, or hydrocyclone for classification and dehydration. Agitator washer can achieve the industry’s highest mud removal rate of 98% and is a key cleaning equipment for providing high-purity raw materials for subsequent mineral processing.

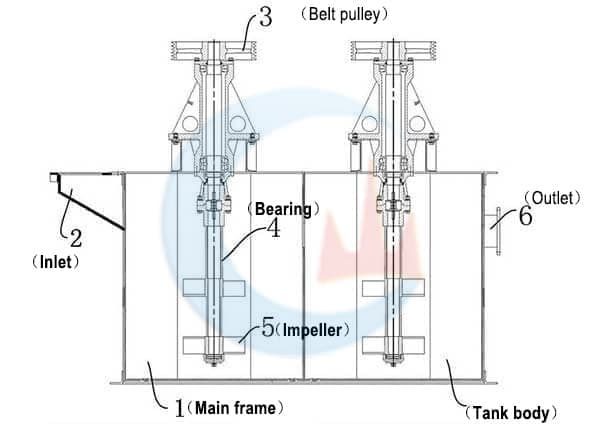

Principle and structure of Attrition Scrubbing Machine

Working principle

The material enters the cavity of the scrubber through the feeding pipe, and is mixed with water to form slurry. Under the strong agitation of the impeller, the slurry produces severe turbulence. The motor drives the main shaft to rotate through the pulley, and the blades generate a negative pressure zone. When the material is fully stirred and washed, it is pushed out by the blades and flows along the barrel wall. By vigorously agitating the granules, the machine removes unwanted materials such as clay, iron oxide, and organics that can cause cloudiness in the final product. Due to the continuous feeding of materials, the scrubbed materials are continuously discharged from the ore discharge port to complete the scrubbing work. Depending on the situation, adding chemicals can also help separate impurities.

Structural characteristics

- Wear-resistant components: The inner wall of the tank and the impeller surface are lined with wear-resistant rubber or high-chromium alloy.

- Tank structure: mostly polygonal or specific structure, which can produce “folding effect” to avoid overall material rotation and scrubbing dead corners, extend the slurry circulation path, and improve processing uniformity.

- Self-cleaning unit: A built-in filter screen and rotating cleaning brush are linked to prevent mud clogging.

- Drive system: The main shaft is connected via a V-belt or hardened gear reducer, supporting variable frequency speed regulation.

why choose JXSC attrition scrubbing machine

features & Advantages of attrition scrubbing machine

1. High cleaning intensity: The unique configuration of the tank and impeller increases the energy density of the mineral particle collision, and the impurity stripping rate reaches 98%, which is particularly effective for stubborn cement.

2. The tank lining and impeller are wear-resistant materials with high anti-corrosion and wear resistance.

3. The unique tank structure and impeller configuration increase the scrubbing strength by about 30% compared with the traditional scrubbing machine of the same specification;

4. It can be combined with magnetic separation, flotation and other equipment to further purify minerals.

5. This scrubber can remove more than 90% of clay, which is more thorough than traditional water washing tanks.

6. Key components such as impellers and stirring shafts are made of high chromium alloy or rubber lining to reduce wear.

7. A circulating water system is usually used to reuse wash water, thus reducing the waste of water resources.

models & specifications

Model | Volume(m³) | Feeding Size(mm) | Feeding density(%) | Motor Power(kw) | Diamension | Weight(kg) |

GSC1-1 | 1 | ≤5 | 50-60 | 11 | 1420x1310x1860 | 1300 |

GSC1-2 | 2 | ≤5 | 50-60 | 11×2 | 2340x1310x1860 | 2500 |

GSC2-1 | 2 | ≤5 | 50-60 | 30 | 2150x1900x2780 | 3200 |

GSC2-2 | 4 | ≤5 | 50-60 | 30×2 | 3530x1900x2780 | 5300 |

GSC4-1 | 4 | ≤5 | 50-60 | 55 | 2596x2800x3441 | 3800 |

GSC4-2 | 8 | ≤5 | 50-60 | 55×2 | 4430x2800x3441 | 7500 |

GSC6-2 | 12 | ≤5 | 50-60 | 90×2 | 4900x3200x4100 | 9500 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.