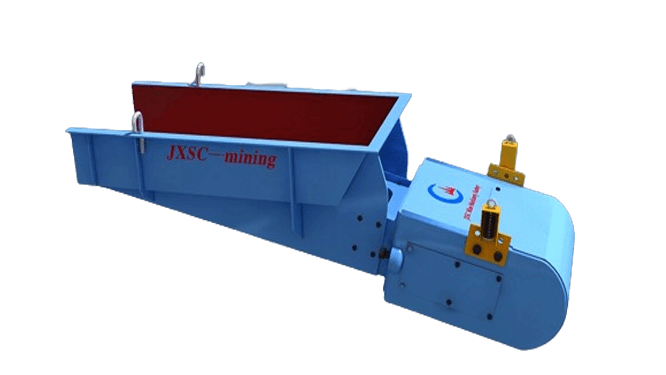

Belt Conveyor

Capacity: 10-350TPH

Feeding: <800mm

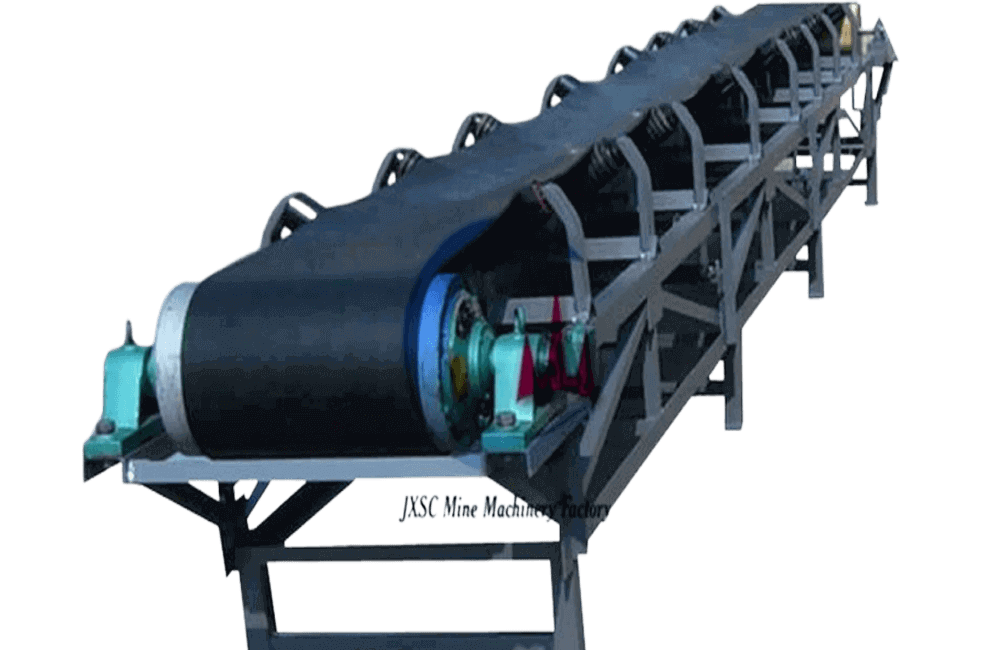

Application: The belt conveyor is designed to handle and transport various materials in mining and mineral processing plants. It can transport various rocks or minerals in bulk or large blocks, such as transporting large volumes of resources and processed ores, including gravel, sand, coal, stone, ore, aggregate, and alluvial materials, etc.

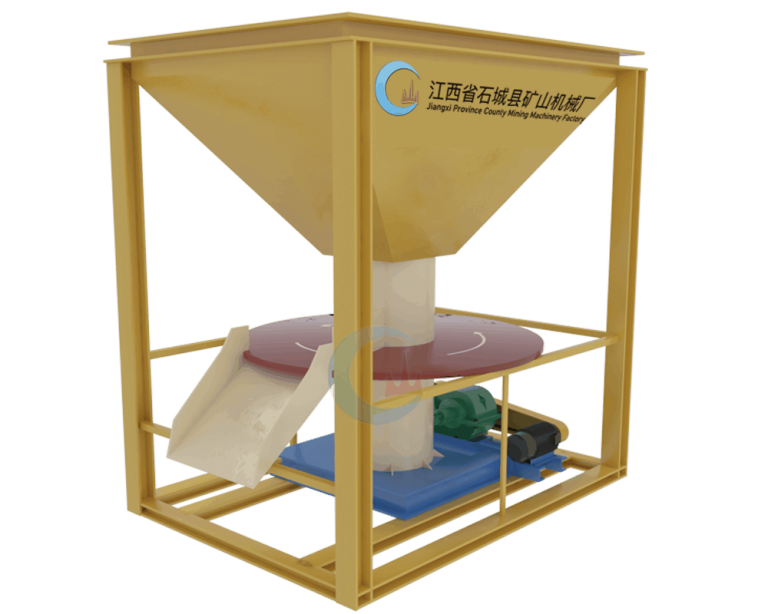

Products display

introduction of belt conveyor

Belt conveyors apply to all locations, working environments, technical performances, and material types, fully meeting various mining or mineral processing conditions. It is a feeding equipment that uses conveyor belt as traction and load-bearing component to continuously transport loose materials and piece items. It can efficiently and smoothly transport various materials to the receiving equipment, providing a strong guarantee for the smooth progress of the production process. The belt conveyors can seamlessly integrate with the crushing process, receiving, and handling material from the production line. Its length can be customized, the horizontal or tilt angle can be flexibly adjusted, and it has strong adaptability.

Compared to other conveying methods, JXSC belt conveyors offer the core advantages of long transport distances, high transport capacity, and low energy consumption. At the same time, it supports multiple layout forms such as horizontal, inclined (maximum inclination 30°), and turning. Modern intelligent belt conveyors are also integrated with advanced functions such as anti-deviation, slip detection, and self-cleaning, and have become an indispensable key equipment for automated production lines.

principle and structure of belt conveyor

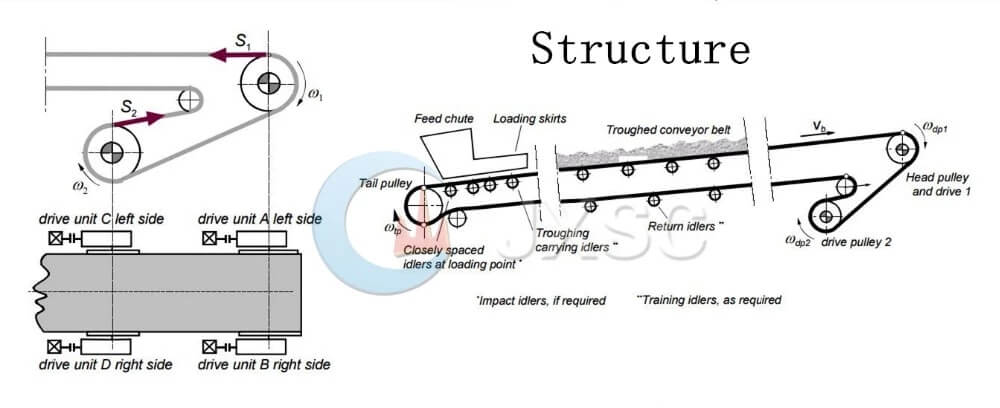

Working principle

The belt conveyor mainly comprises two end rollers and a closed conveyor belt tightly sleeved on them. The pulley that drives the conveyor belt to rotate is called a drive pulley (drive pulley); the other pulley that only changes the direction of movement of the conveyor belt is called a reversing pulley.

Material is fed on the feed-side and lands on the rotating conveyor belt, which relies on the conveyor belt friction to deliver to the discharge end. It has the advantages of strong conveying capacity, long conveying distance, large transport volume and continuous conveying.

Structural characteristics

- Conveyor belt: The core load-bearing component, made of materials such as rubber, plastic, and steel.

- Belt rollers: Drive rollers (transmitting power) and bend rollers (changing the direction of the conveyor belt).

- Idler rollers: Evenly distributed beneath the conveyor frame, supporting the conveyor belt and material.

- Tensioning device: Maintains proper belt tension to prevent slippage or deviation.

- Drive: The motor, reducer, and drive rollers provide the power source.

why choose JXSC belt conveyor

Features & advantages

√ Efficient and continuous conveying: Automates the entire material process from feeding to unloading, meeting small- to large-scale conveying needs for powdered, granular, or bagged materials.

√ Energy saving: Energy-saving motors and optimized transmission design reduce energy consumption by 15%-30%.

√ Cost-effective: Standardized component production reduces procurement and maintenance costs.

√ Safe and reliable: Multiple protective devices (anti-tear sensors, emergency brake) ensure zero-accident operation.

√ Environmentally friendly: Large contact area between the conveyor belt and rollers ensures smooth material conveying, with noise levels ≤75 decibels.

√ Highly adaptable: The frame is treated with corrosion protection, and the belt is available in acid-, alkali-, and high-temperature-resistant materials, enabling long-term operation in harsh environments such as dust, humidity, and open air.

√ Flexible adjustment: Available models include trough, flat, climbing, and turning types to accommodate complex plant layouts. Easily integrated into mineral processing and aggregate production lines.

√ Intelligent control: Optional PLC or IoT remote monitoring provides real-time monitoring of belt tension, deviation, and fault warnings.

√ Configurable: Supports customization of single-machine conveying length and bandwidth, special solutions such as explosion-proof or anti-corrosion.

models & specifications

Model | Capacity | Max length | Belt width | Speed | Upper slope | Power | Drum dia | Roller Dia |

DT75-500 | 87 | 20 | 500 | 1 | <20 | 5.5 | 500 | 89 |

DT75-650 | 127 | 20 | 650 | 1 | <20 | 7.5 | 500 | 89 |

DT75-800 | 198 | 15 | 800 | 1 | <20 | 7.5 | 630 | 89 |

DT75-1000 | 507 | 20 | 1000 | 1.25 | <20 | 11 | 800 | 108 |

DT75-1200 | 742 | 20 | 1200 | 1.25 | <20 | 15 | 1000 | 108 |

DT75-1400 | 1032 | 30 | 1400 | 1.25 | <20 | 22 | 1000 | 133 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.