Belt Pressure Filter

Capacity: 0.5-30TPH

Application: The belt pressure filter mainly used in sewage treatment plants, metallurgy, chemical industry, coal washing, mining, sand and gravel plants, artificial sand making, sand washing plants, and wastewater treatment in environmental protection projects; dehydration and solid-liquid separation operations such as tailings mud, mineral processing wastewater, sand washing mud, sand plant sludge, etc.

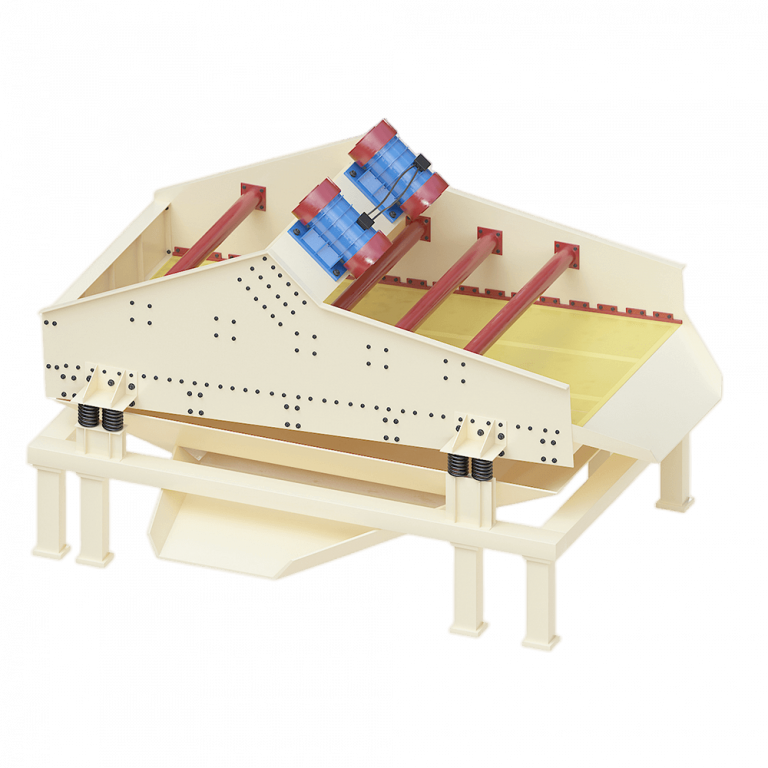

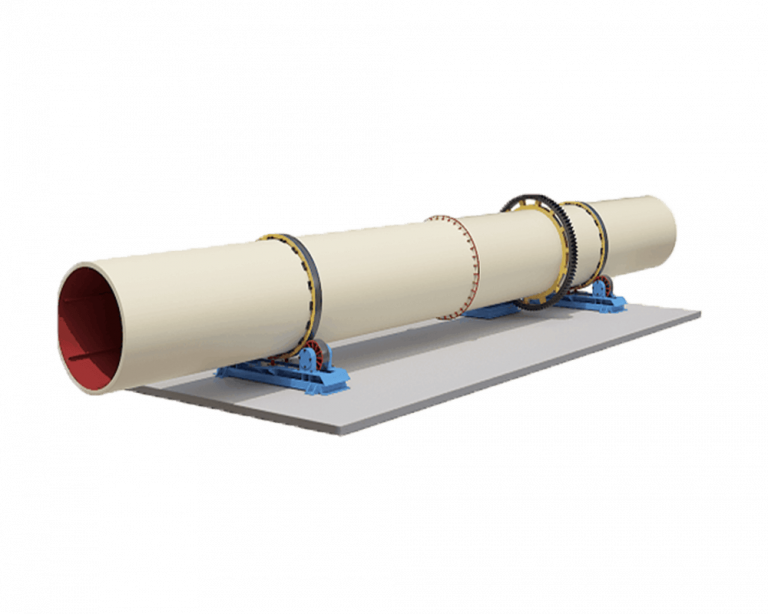

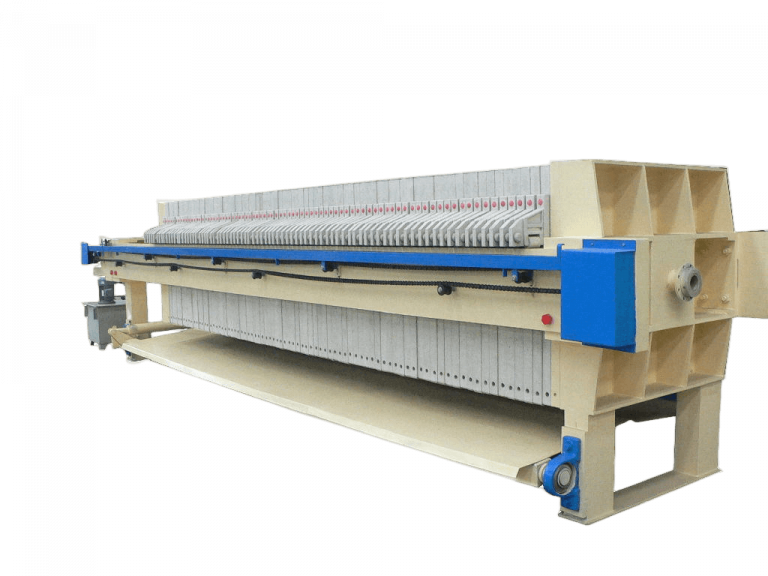

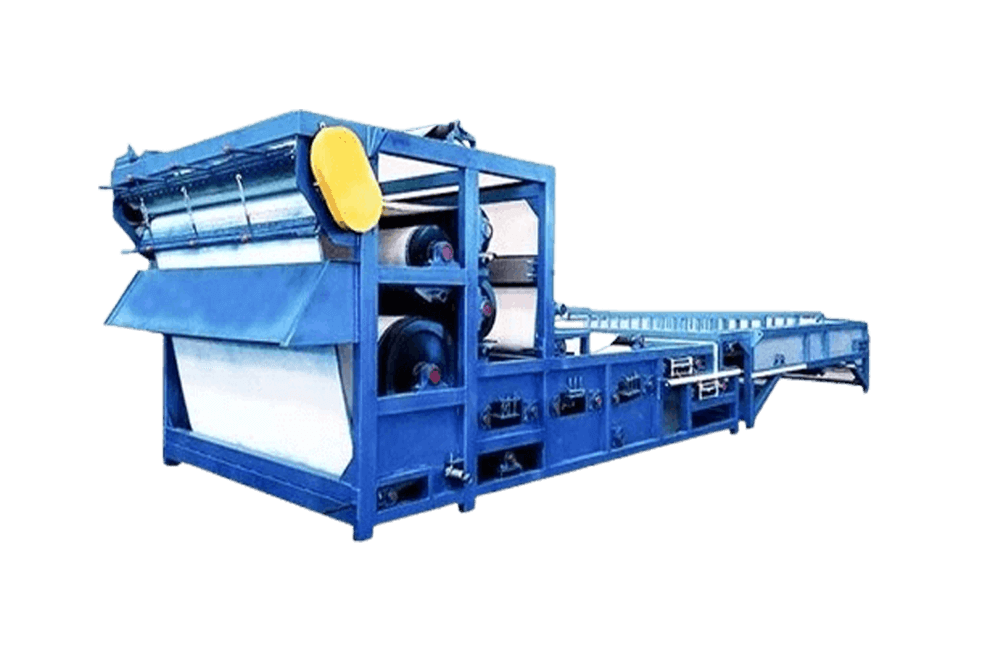

Products display

Introduction of belt pressure filter

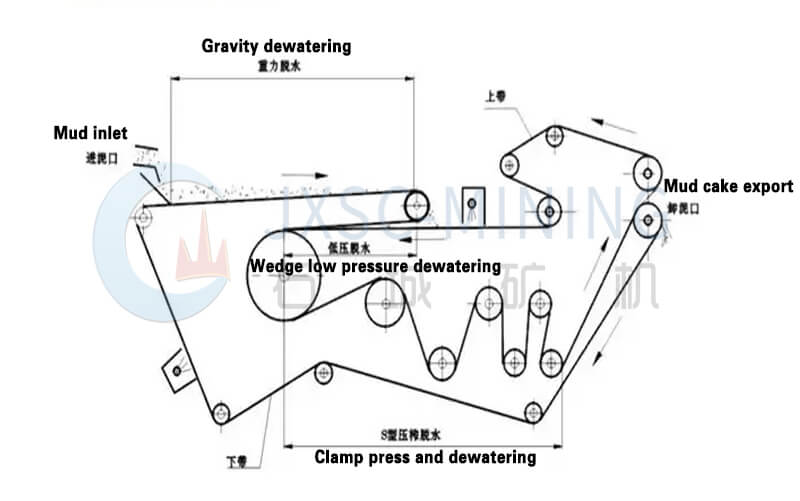

The belt pressure filter is a solid-liquid separation equipment that mainly squeezes sludge to force water through a permeable medium to achieve sludge dehydration, dry slurry transportation, and clean water recycling. Among them, the dehydration process mainly has four stages: pretreatment, gravity dehydration, wedge zone pre-pressure dehydration, and press dehydration. In the mineral processing plant, belt pressure filter is especially suitable for filtering and dewatering sludge from sand washing plants, coarse-grained and heavy mineral (such as tungsten and tin) concentrates, and can also be used for filtering and dehydrating coarse-grained coal in coal preparation plants.

This equipment utilizes a high-strength filter belt (typically made of polyester or polyamide) as the filter medium, combined with an intelligent tensioning and correction system to ensure long-term stable operation.

Compared to plate and frame filter presses, belt filter presses offer significant advantages, including high throughput, low energy consumption, and a high degree of automation. It is particularly suitable for continuous dehydration of medium-concentration suspensions and is one of the core dehydration equipment in modern sewage treatment plants and mineral processing plants.

Structure and principle of belt pressure filter

Working principle

The belt filter press uses the crawler belt’s tension and the pressing hub’s extruder to achieve solid-liquid separation. Under the action of flocculant, the fine particles of the material aggregate into flocs and precipitate into sludge. The sludge is evenly sent to the mesh belt through the distribution hopper and runs forward with the filter belt. When the material passes between the two circulation belts, it will be under pressure, forming a wedge-shaped area at the entrance to complete slight squeeze dehydration. Then, the upper and lower filter belts clamp the material around the press roller for repeated squeezing and shearing. Finally, mud and water can be separated to the greatest extent, and a filter cake can be formed and discharged.

Structural characteristics

- Filter belt system: Two high-strength monofilament or multi-layer woven polyester filter belts, one above the other.

- Roller assembly: Consists of a drive roller, guide rollers, tensioning rollers, and multiple sets of press rollers.

- Pressure system: Pneumatic/hydraulic guides prevent belt deviation and wear.

- Cleaning system: The return section of the filter belt is equipped with high-pressure spray and brush roller scrubbing, and the cleaning water is recycled.

Why choose JXSC belt pressure filter

features & Advantages

1. It adopts fully automatic water removal, no manual supervision is required, and continuous production is possible.

2. The belt pressure filter has large processing capacity and can quickly squeeze the mud into dry mud, and the filter cake has low moisture content.

3. The pressed water is clean water, which can be recycled or discharged, and has good environmental protection effect.

4. Integrated design of concentration, press filtration and dehydration, ultra-long gravity dehydration zone, high efficiency.

5. PLC+touch screen control, supports remote monitoring (optional IoT module), and enables fully automatic feeding, dosing, squeezing, and cleaning.

6. The belt speed and pressure can be automatically adjusted according to the sludge viscosity to ensure uniform filter cake.

7. Gravity + mechanical pressing combined dehydration is 2-3 times more efficient than gravity dehydration alone.

8. The fully enclosed design reduces odor and dust, and operates with low noise.

models & specifications

Model | Capacity(TPH) | Motor(kw) | Air compressor power(kw) | Belt width(mm) | Slurry feed concentration(%) | Output concentration(%) | L*W*H(mm) |

TXYL500 | 0.5-4 | 0.75 | 1.1 | 500 | 3-8 | 25-40 | 4290*900*1840 |

TXYL1000 | 3-6.5 | 1.5 | 2.2 | 1000 | 3-8 | 25-40 | 4790*1400*2040 |

TXYL1500 | 4-9.5 | 1.5 | 6 | 1500 | 3-8 | 25-40 | 4790*1900*2040 |

TXYL2000 | 5-13 | 2.2 | 4 | 2000 | 3-8 | 25-40 | 4790*1900*2040 |

TXYL2500 | 7-15 | 4 | 5.5 | 2500 | 3-8 | 25-40 | 5300*2900*2250 |

TXYL3000 | 8-20 | 5.5 | 5.5 | 3000 | 3-8 | 25-40 | 5300*2900*2250 |

TXYL4000 | 12-30 | 7.5 | 7.5 | 4000 | 3-8 | 25-40 | 5800*4400*2250 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.