Washing & screening Equipment

JXSC mining washing and screening equipment is commonly used in construction, gravel plants or mining plants. Mainly including wheeled sand washer, spiral sand washer, trommel scrubber, trommel screen, vibrating screen, mobile gold washing plant, silica sand attrition scrubber, fine sand recovery machine, linear vibrating screen, gyratory swing vibration screen, rotary vibtating sieve, etc. Among them, the water of the sand washing machine can be recycled, which is environmentally friendly; the sand washing loss is small and the production efficiency is high. Our gold trommel is an integrated washing and screening equipment, the screen hole is not easy to block, and the operation is stable and reliable.

Washing & screening equipment for sale

trommel screen

Capacity: 1-100TPH

Application: Sand and gravel aggregate and ore classifying, screening, washing, processing; gold, diamond ore, silica sand, manganese ore, iron ore, quartz sand and other ore with low mud content.

Trommel scrubber

Capacity: 1-200 TPH

Application: It is widely used to wash rock, ore, sand, gravel and aggregates that contain water-soluble clays; effectively wash and screen ore with high mud content and get cleaner products.

Sand washing machine

Capacity: 15-400 t/h

Types: Wheel or Spiral type

Application: quartz sand, limestone, river pebbles, river sand, calcite, aluminum ore and other natural sand and machine-made sand washing; or widely uesd in sand making plant.

Log washer

Capacity: 1-100TPH

Application: washing of manganese ore, iron ore, phosphate rock, copper ore, barite, hard kaolin, river pebble, granite, basalt, limestone, calcite, quartz stone, diabase and other ores, stones

Attrition Scrubbing Machine

Volume: 1-10 m³

Feeding Size: ≤5mm

Application: scrubbing silica sand(quartz sand), potassium albite feldspar ore, glass sand; ore slime, and removal of impurities on the surface of minerals

Fine Sand Recycling Machine

Capacity: 30-250TPH

Application: It is mainly used for dewatering and recycling fine sand or fine materials (slurry materials below 0.16mm). It is widely used in sand washing, tailings, silica/quartz sand processing plant, etc.

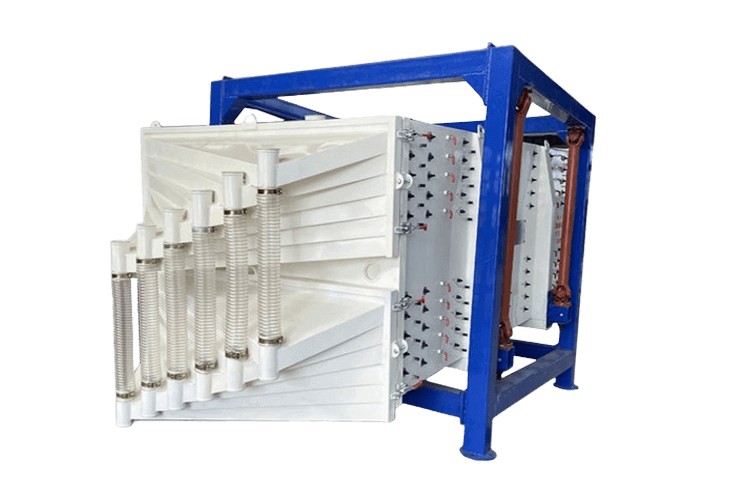

Vibrating Screen

Capacity: 10-250t/h

Layer: 1-4 available

screen mesh: customized

Application: screening rock, sand, gold, copper, manganese, diamond ore, etc.

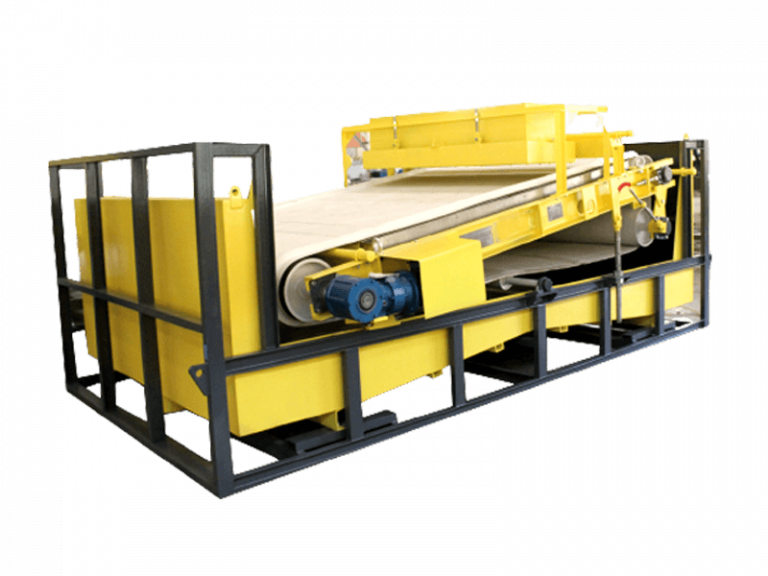

Linear Vibrating Screen

Screen: Multiple discharge holes can be designed

Applicable materials: Classification and screening of various non-sticky, dry powdery materials such as limestone, quartz, sand, rocks, aggregates, ores, etc.

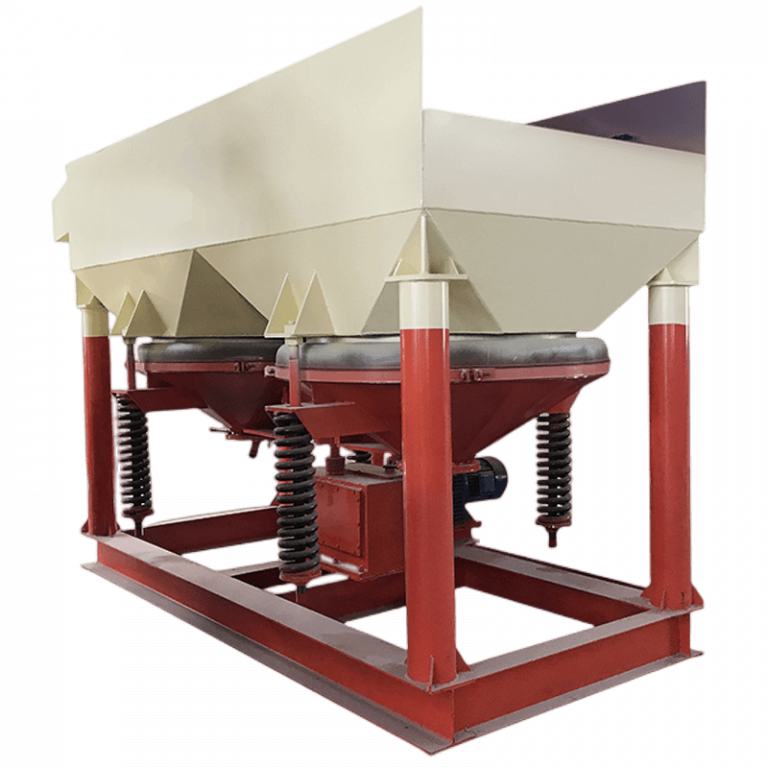

Gyratory Swing Vibration Screen

Layer: 1-5 or customized

Application: screening and classification of silica sand, quartz sand and other granular and mineral powders.

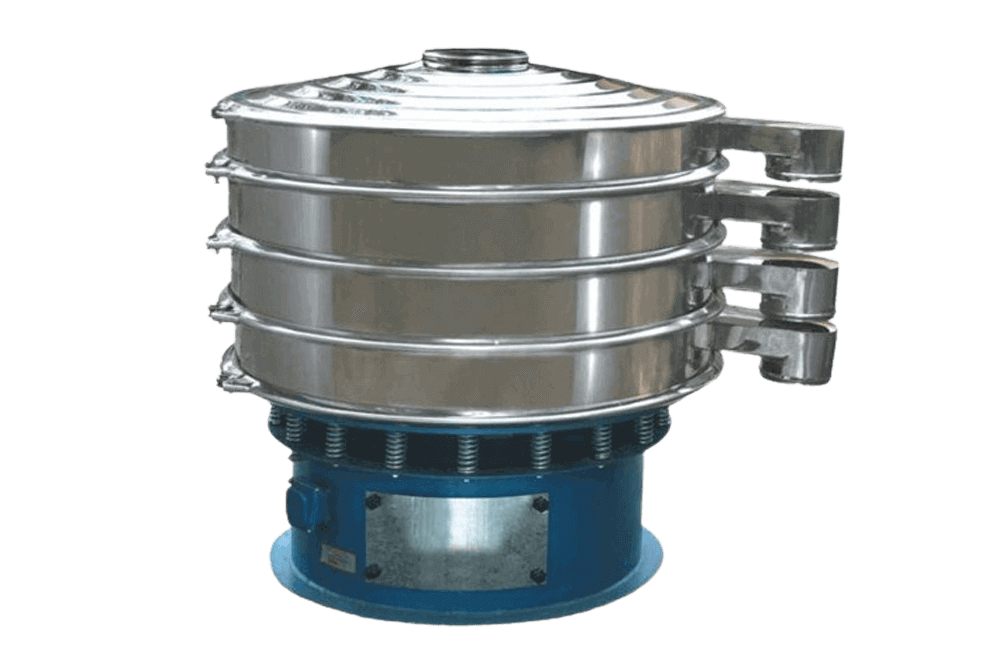

Rotary Vibrating Sieve

Layer: 1-5

Application: Widely used in food, environmental protection, metallurgy, mining industries; screening, filtration and classification of alumina, silica sand, metal powder, etc.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, no investing)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.