Disc Feeder

Feeding capacity: 1.8-88 t/h

Max feeding size: ≤80mm

Application: Disc feeder commonly used in mining operations, construction, pharmaceutical manufacturing, gravel and aggregate processing industries; coal powder, cement, limestone, shale, coal gangue, rare earth, sand, and other materials are continuously supplied and transported to next various equipment.

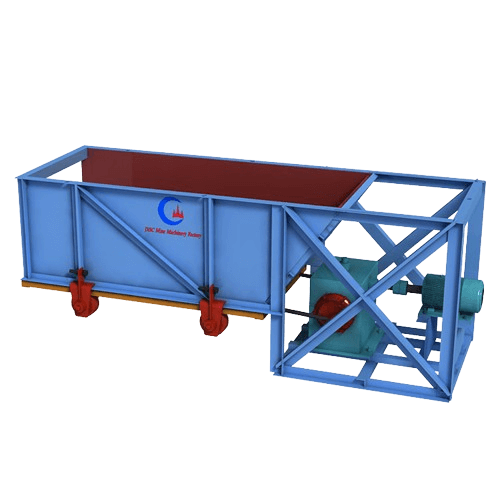

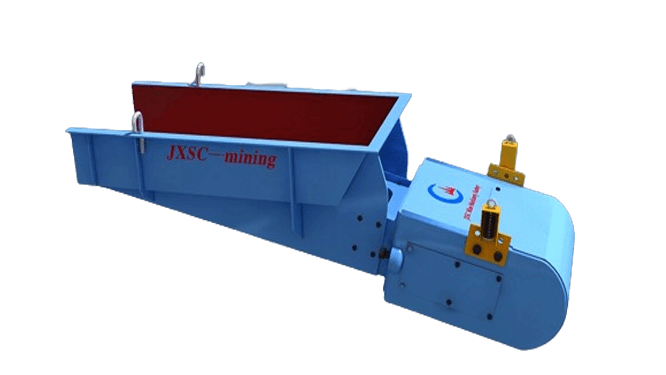

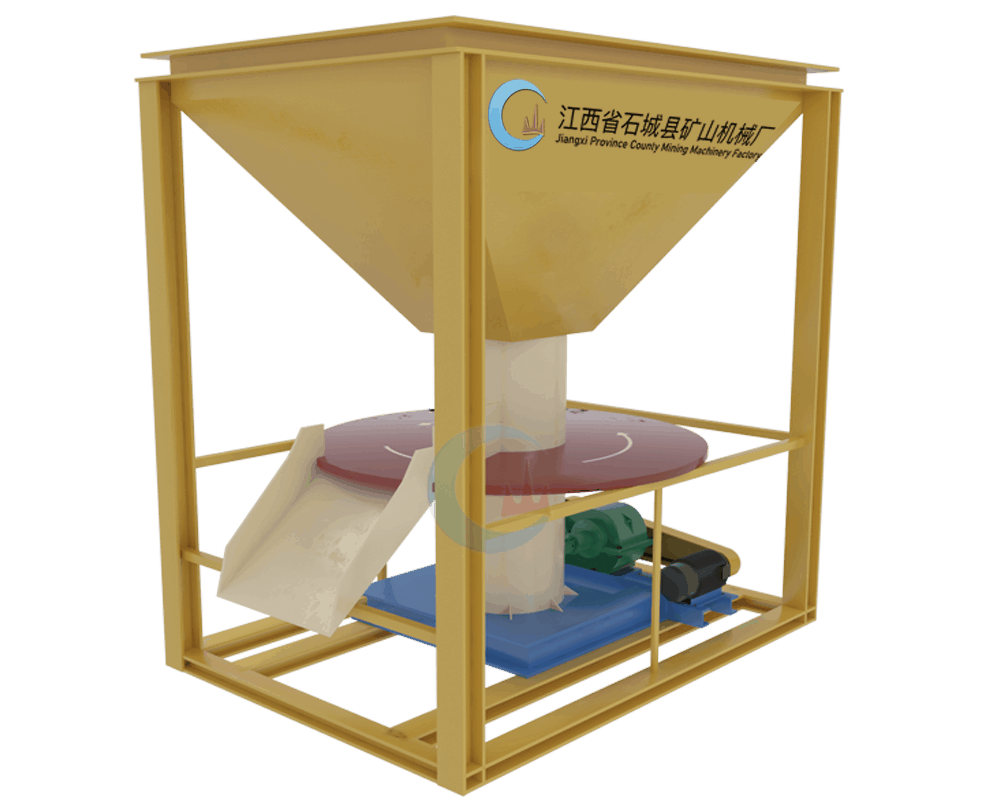

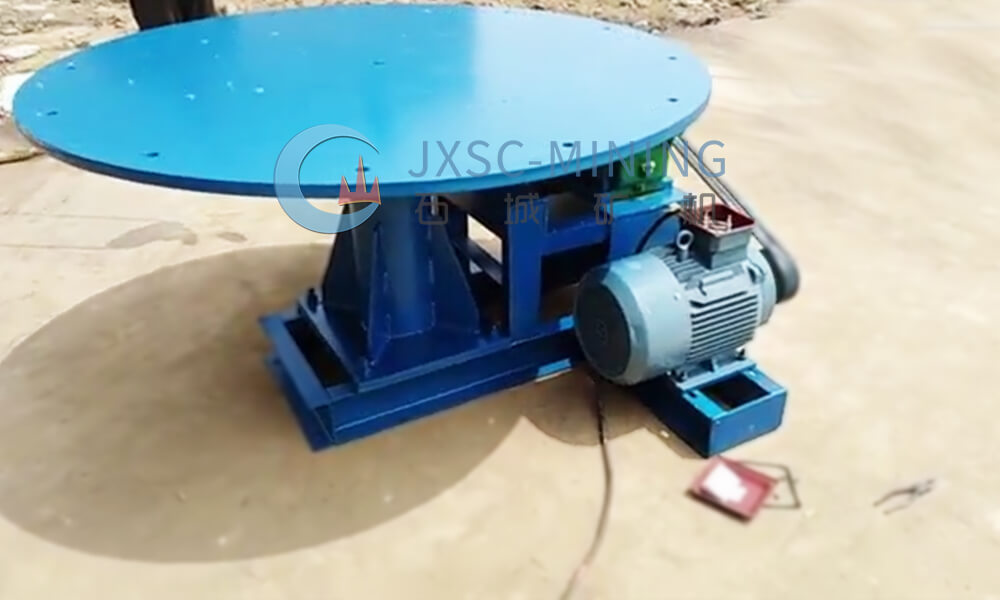

Products display

Introduction of Disc feeder

The disc feeder is a common equipment used to evenly feeding medium- and fine-grained materials. It mainly allows the materials in the silo to be discharged and fed into the next equipment continuously and evenly, saving labor. It is usually suspended on a steel structure or installed at the discharge port of a hopper or silo for continuous feeding.

This feeder primarily utilizes a rotating disc to drive the material, achieving precise feeding by adjusting the speed and scraper position. It is commonly used for the stable conveying of powdered, granular, and small-piece materials. It has the characteristics of compact structure, smooth operation, and easy adjustment. It is a key feeding equipment connecting the silo and subsequent equipment in the production line, and widely serves the continuous production processes in the mining, chemical, building materials and other industries.

Principle and structure of disc feeder

working principle of Disc feeder

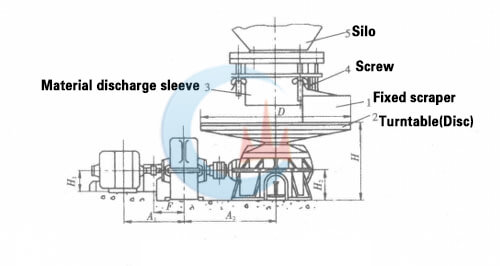

The disc feeder is mainly composed of a motor, a reduction device, a disc, a sleeve, a scraper, a feeding adjustment device and other parts. The motor drives the disc through the reducer through the coupling. When rotating, the materials in the silo move together with the disc, and rely on the gravity of the materials and the forced action of the working mechanism of the feeder to lower the material sleeve onto the lining of the disc. Then the material is scraped off by a fixed scraper, rotates to the discharge port, and pours into the next equipment.

Structural characteristics

- Drive: Consists of a motor and a reducer, providing power for the disc’s rotation.

- Disc: The main component, constructed of steel or lined with wear-resistant material, carries and conveys the material.

- Scraper: A fixed scraper (scrapes material off the disc into the discharge port); an adjustable guide plate (optimizes material flow).

- Silo connection: Connects to the silo from above, ensuring a continuous supply of material.

- Enclosure (optional): Prevents dust from escaping, meeting environmental requirements.

why choose JXSC Disc feeder

Features & advantages

√ Widely applicable: Designed for powdery and fine-particle materials, the disc’s smooth surface and adjustable speed prevent clogging caused by fine materials.

√ Smooth operation: It precisely controls the flow of bulk materials with a wide adjustment range and a large load capacity.

√ High adjustment precision: Driven by a variable frequency motor, the gap between the disc and the scraper is adjustable, helping to prevent overloads on downstream equipment and minimize waste.

√ Easy to use: Compact, small footprint, lightweight, and featuring an integrated shock absorber.

√ Cost-effective: The disc feeder features a wear-resistant liner for a long service life, requiring minimal maintenance and operating costs.

Environmentally Friendly: An optional enclosed structure effectively reduces dust (dust control rate ≥ 90%).

models & specifications

Model | Disk diameter(mm) | Rotate speed(r/min) | Max feeding size(mm) | Feeding capacity(t/h) | Motoe power(kw) | Weight(kg) |

YG 600 | D600 | 10 | 25 | 1.8-4 | 1.1 | 410 |

YG 800 | D800 | 9 | 30 | 3.5-7 | 1.5 | 600 |

YG 1000 | D1000 | 9 | 40 | 1.8-16.7 | 2.2 | 800 |

YG 1300 | D1300 | 9 | 50 | 4-28 | 3 | 1110 |

YG 1600 | D1600 | 7 | 60 | 7-49 | 4 | 1980 |

YG 1800 | D1800 | 7 | 70 | 9-60 | 5.5 | 3070 |

YG 2000 | D2000 | 7 | 80 | 14-88 | 5.5 | 3260 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.