Mineral Processing » Equipment » plate Filter Press

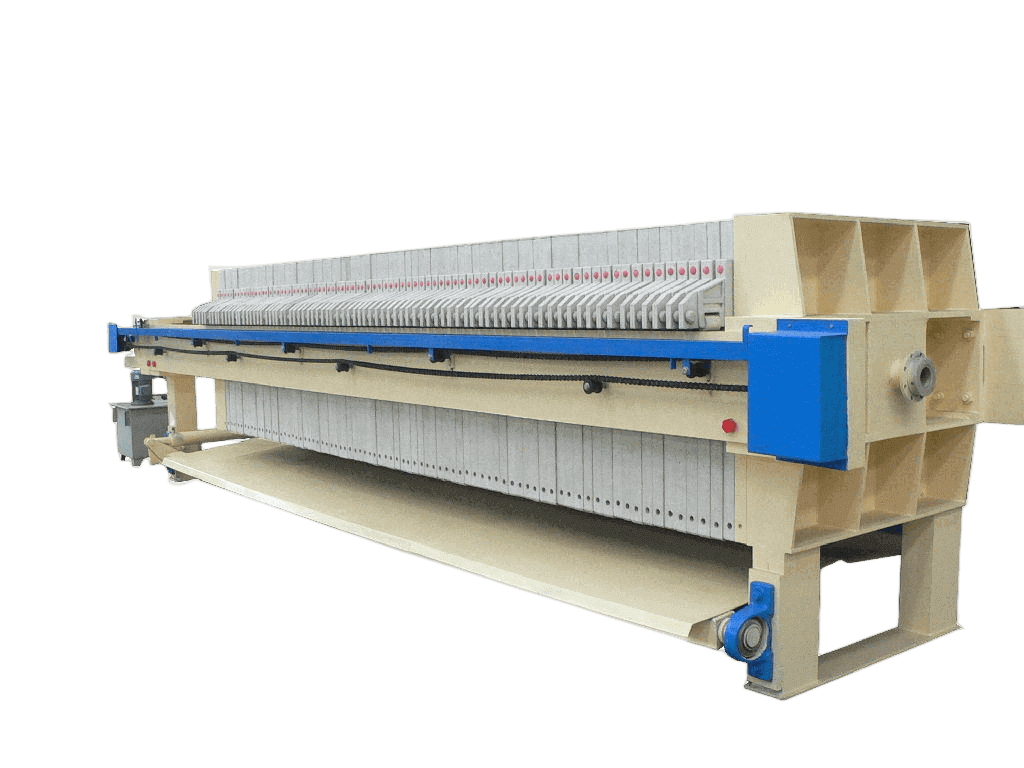

Plate Filter Press

Filter area: 50-500 m²

Cake thickness: 30mm

Application: The plate and frame filter press is often used as tailings treatment equipment in mineral processing plants, such as gold, lead-zinc, copper, tungsten, iron, fluorite ore, and other mine tailings processing lines; sludge dewatering and solids separation in wastewater treatment plants.

Products display

Introduction of plate filter press

The plate filter press, also called chamber filter press, plate and frame filter press is some industries’ most commonly used pressure filter machine. By applying a certain pressure between filter plates, this batch-operated filter makes it possible to produce filter cakes that reach the desired moisture.

It is an intermittent solid-liquid separation equipment. It is commonly used for concentrate dehydration, tailings dry discharge, and sludge treatment. It is especially suitable for processing sticky and fine materials, such as kaolin, activated sludge, etc. It can dehydrate slurry with a moisture content of 80%-95% to 30%-60%, and the moisture content of the finished filter cake can reach the dry pile standard. The plate and frame filter press achieves efficient solid-liquid separation through high-pressure mechanical extrusion. It has the advantages of sturdy and durable structure, strong adaptability and high dehydration efficiency. It is the core dehydration equipment in sludge concentration, mineral processing and other fields.

When your investment is limited and while can’t afford a more expensive continuous pressure or vacuum filter, or your filter capacity is rather small, the filter press could be the best choice when choosing a filter.

Principle and structure of plate filter press

Working principle

The plate and frame filter press consists of chambers arranged alternately with filter plates and frames. The feed pump hydraulically pumps the suspension into the filter chamber, and the filter residue is formed on the filter cloth until the filter chamber is filled to form a filter cake. The filtrate passes through the filter cloth and flows along the groove of the filter plate to the channel of the outlet hole below, where it is discharged in a concentrated manner. After the filtration, the filter residue can be washed with clean water. After washing, sometimes compressed air is introduced to remove the remaining washing liquid. Then open the filter press to remove the filter residue and clean the filter cloth. Press the plate and frame again to start the next working cycle.

Structural characteristics

- Filter unit: Alternating filter plates and filter frames form independent filter chambers through concave and convex sealing surfaces.

- Clamping mechanism: Hydraulic or mechanical clamping is employed.

- Feed and discharge system: Top/side feed ports are compatible with centrifugal pumps, and filtrate is discharged through underflow/open flow channels at the bottom of the filter plates.

- Automatic (Optional): PLC control and a pull-out trolley enable automatic unloading and cleaning.

Why Choose JXSC plate filter press

features & Advantages of plate filter press

1. The high-pressure filtration technology can quickly and efficiently separate solids and liquids.

2. It consumes less energy, consumes less electricity, and occupies a small area.

3. The filtered mud cake is relatively dry, has less moisture content, and has high dehydration efficiency.

4. The layout is simple, and the large filtration area can adapt to the operation of projects with higher intensity.

5. It has strong adaptability to materials and is suitable for dehydration treatment of various types of ore dressing, tailings, sludge, etc.

6. Optional PLC fully automatic control enables remote monitoring, fault alarm, and automatic unloading, saving 70% of labor costs.

7. The filter plate is made of reinforced polypropylene + steel frame, which is resistant to acid and alkali, anti-deformation, and very long service life.

8. It effectively reduces the discharge of wastewater and solid waste, and is an environmentally friendly dehydration equipment.

models & specifications

| Specification Model | Filter area m² | Outside dimensions of the board (mm) | Cake thickness (mm) | Filter chamber volume (L) | Number of filter plates (pcs) | Filter pressure (Mpa) | Overall quality (Kg) | Dimensions (L*W*H)(mm) | Foundation size | ||

| L | B | C | |||||||||

| XAMZ50/1000-30UBK | 50 | 1000*1000 | 30 | 750 | 28 | ≤ 0.6 | 4128 | 4040*1500*1400 | 3120 | 560 | 1100 |

| XAMZ60/1000-30UBK | 60 | 900 | 34 | 4636 | 4460*1500*1400 | 3540 | |||||

| XAMZ70/1000-30UBK | 80 | 1303 | 40 | 3740 | 4760*1500*1400 | 3840 | |||||

| XAMZ80/1000-30UBK | 90 | 1468 | 46 | 4040 | 5120*1500*1400 | 4100 | |||||

| XAMZ100/1000-30UBK | 100 | 1635 | 57 | 4360 | 5780*1500*1400 | 4750 | |||||

| XAMZ120/1000-30UBK | 120 | 1966 | 69 | 4960 | 6500*1500*1400 | 5480 | |||||

| XAMZ100/1250-30UBK | 100 | 1250*1250 | 1500 | 36 | ≤ 0.6 | 8307 | 5170*1850*1600 | 3990 | 900 | 1360 | |

| XAMZ120/1250-30UBK | 120 | 1800 | 43 | 6600 | 5625*1850*1600 | 4350 | |||||

| XAMZ140/1250-30UBK | 140 | 2120 | 51 | 7200 | 6145*1850*1600 | 4820 | |||||

| XAMZ160/1250-30UBK | 160 | 2280 | 58 | 7500 | 6600*1850*1600 | 5250 | |||||

| XAMZ180/1250-30UBK | 180 | 2400 | 65 | 7750 | 7055*1850*1600 | 5870 | |||||

| XAMZ200/1250-30UBK | 200 | 2720 | 72 | 8500 | 7510*1850*1600 | 6330 | |||||

| XAMZ220/1250-30UBK | 220 | 3000 | 80 | 9000 | 8030*1850*1600 | 6850 | |||||

| XAMZ250/1250-30UBK | 250 | 3800 | 91 | 10500 | 8745*1850*1600 | 7560 | |||||

| XAMZ200/1500-30UBK | 200 | 1500*1500 | 3000 | 49 | ≤ 0.6 | 20030 | 6640*2100*1820 | 5360 | 1150 | 1700 | |

| XAMZ250/1500-30UBK | 250 | 3760 | 61 | 17680 | 7480*2100*1820 | 6200 | |||||

| XAMZ300/1500-30UBK | 300 | 4480 | 74 | 19200 | 8390*2100*1820 | 7110 | |||||

| XAMZ350/1500-30UBK | 350 | 5250 | 86 | 21300 | 9230*2100*1820 | 7950 | |||||

| XAMZ400/1500-30UBK | 400 | 5960 | 99 | 23300 | 10140*2100*1820 | 8860 | |||||

| XAMZ450/1500-30UBK | 450 | 6740 | 111 | 25400 | 10980*2100*1820 | 9700 | |||||

| XAMZ500/1500-30UBK | 500 | 7510 | 123 | 27500 | 11820*2100*1820 | 10540 | |||||

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.