High Intensity Magnetic Separator

Capacity: 0.2-9 t/h

Application: High intensity magnetic separator is suitable for the separation of weakly magnetic minerals and non-magnetic minerals such as tantalum niobium, tin, hematite, limonite, manganese ore, chromium ore, ilmenite, monazite, garnet, rutile, zircon, beach sand, etc.

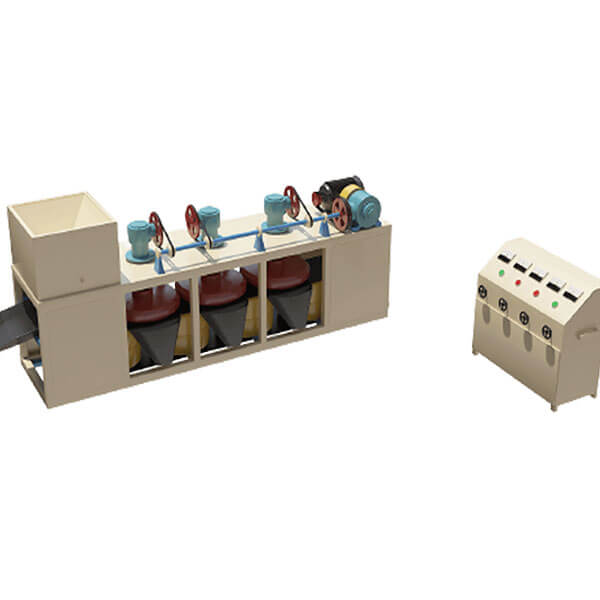

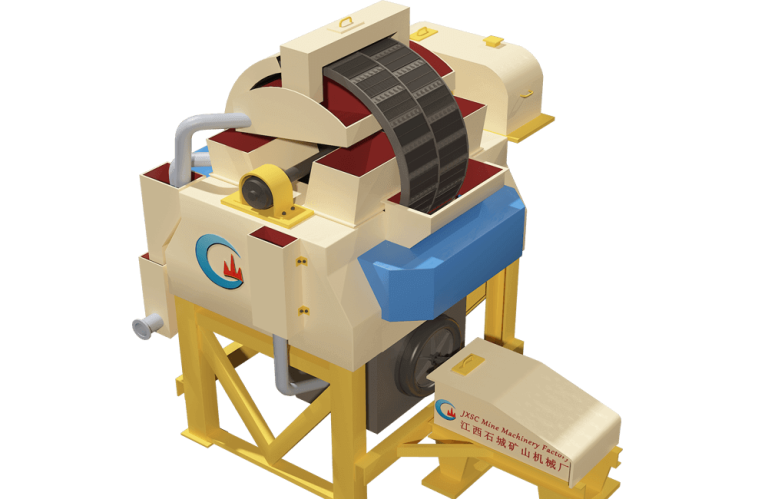

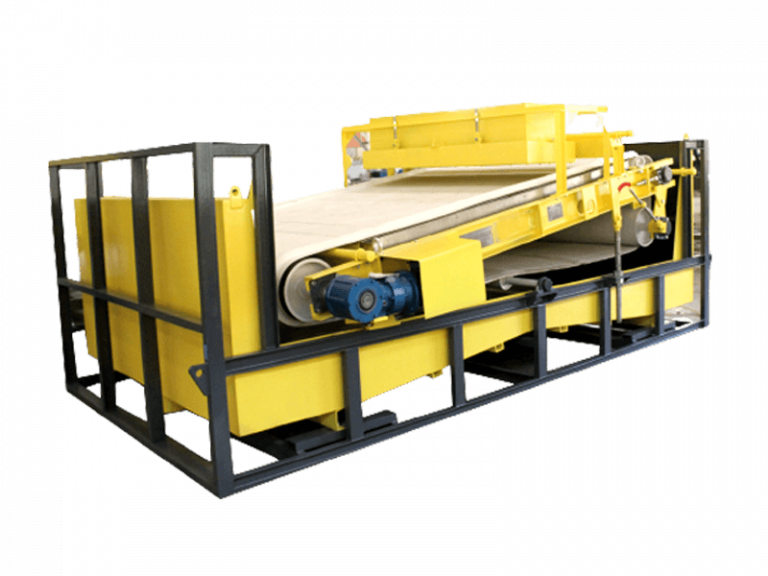

Products display

introduction Of High intensity magnetic separator

High-intensity magnetic separators, or multi-roller magnetic separators, are iron removal/magnetic separation equipment for sorting weak magnetic minerals. It is widely used in limonite, manganese ore, and beach sand mineral processing. This magnetic separator uses a strong magnetic field to effectively separate ferromagnetic materials from non-ferrous metal materials, extracting fine particles from the feed without water or any other media; it can completely ensure product quality and purity, ultimately increasing output and reducing production costs. The high-intensity magnetic separator is often used in the deep separation of iron ore, recovery of rare metals, and removal of impurities from non-metallic ores.

For example, the improvement and reduction of impurities of weakly magnetic minerals such as hematite, limonite, manganese ore, and tungsten ore; the selection of tantalum-niobium ore, rare earth ore, and wolframite; the deep removal of iron and titanium from kaolin, quartz, and feldspar, etc.

It uses high-gradient magnetic field, and multi-roller magnetic system design to achieve efficient enrichment of minerals that are difficult to handle with ordinary magnetic separators under dry or wet conditions. It has the characteristics of extremely high magnetic field intensity, wide adaptability, and excellent recovery rate.

Principle and structure of high intensity magnetic separator

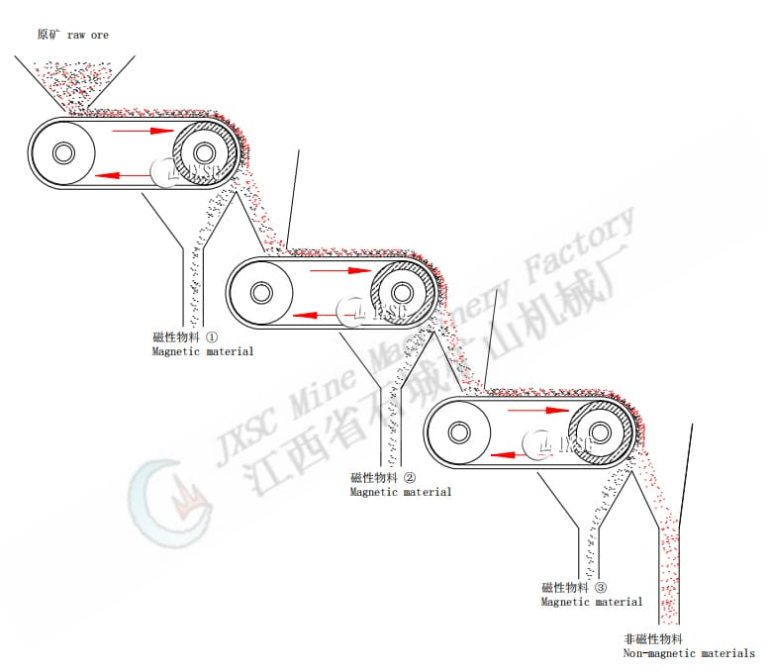

working principle

The materials are evenly distributed on the strong magnetic roller separator belt through the electromagnetic vibrating feeder. When the material passes through the strong magnetic roller, the magnetic material is adsorbed to the strong magnetic roller due to the magnetic adsorption. Non-magnetic and unselected magnetic materials fall directly into the tailings hopper under gravity as the belt rotates. As the annular belt rotates, the magnetic mineral particles fall into the middle ore hopper and the concentrate hopper successively, thereby completing the mineral sorting operation.

Structural characteristics

- Magnetic core: Permanent magnet (NdFeB) or electromagnetic (excitation coil) source, multi-pole alternating magnetic design.

- Sorting mechanism: Drum or belt type.

Drive System: Variable frequency motor + reducer, supporting stepless speed regulation. - Intelligent control: PLC + touch screen control, supporting real-time adjustment of magnetic field strength, speed, and separation thickness.

- Discharging mechanism: Non-magnetic materials fall freely, while magnetic materials are removed using high-pressure air blowing/scraping.

Why choose JXSC High intensity magnetic separator

features & advantages Of High intensity magnetic separator

1. The dry magnetic separator is equipped with an adjustable feeding system, such as a vibrating feeder, which is suitable for feeding different materials evenly.

2. The use of high-performance permanent magnetic materials (such as NdFeB) or electromagnetic systems; high-gradient magnetic field design can improve the recovery effect of fine-grained minerals.

3. This magnetic separator has stable performance, no material blockage, and high iron removal and sorting efficiency.

4. It can achieve effective enrichment of weakly magnetic minerals and significantly reduce the impurity content in the product.

5. The speed of the belt is controlled by a frequency converter, and the rotation speed of the magnetic roller is adjustable.

6. The magnetic induction intensity on the surface of the magnetic roller can reach 8000GS-15000GS, with high magnetic induction intensity and large magnetic field gradient.

7. According to user requirements, JXSC high-intensity magnetic separators can be designed as one-four or multi-roller magnetic separation.

models & specifications

Model | Cylinder size | Capacity | Power |

HYF-1060 | D100*600 | 0.2–1 | 0.37 |

HYF-1080 | D100*800 | 0.3–1.4 | 0.37 |

HYF-1210 | D120*1000 | 0.4–2 | 0.55 |

HYF-1610 | D160*1000 | 0.6–2.5 | 0.55 |

HYF-2060 | D200*600 | 0.45–2.3 | 0.55 |

HYF-2010 | D200*1000 | 0.7–3.8 | 0.75 |

HYF-2475 | D240*750 | 0.9–4.5 | 0.75 |

HYF-2410 | D240*1000 | 1.2–5 | 1.1 |

HYF-3060 | D300*600 | 1–4.5 | 1.1 |

HYF-3010 | D300*1000 | 1.6–7 | 1.1 |

HYF-3860 | D380*600 | 1.8–5.5 | 1.1 |

HYF-3810 | D380*1000 | 2.8–9 | 1.5 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.