Plate Magnetic Separator

Capacity: 8-35 t/h

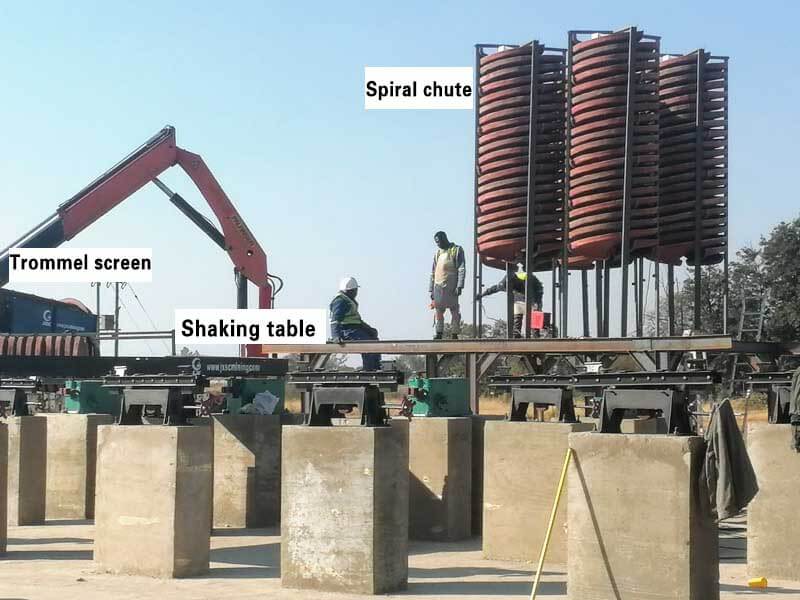

Application: Wet magnetic separator is mainly used for wet separation of various weakly magnetic metal minerals such as magnetite, hematite, limonite, garnet, ilmenite, tungsten ore, and iron removal process of silica sand and kaolin.

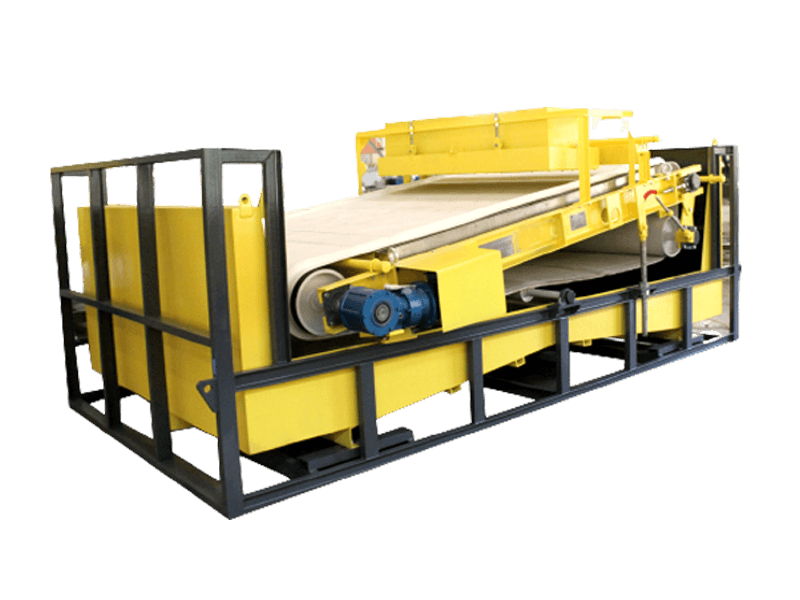

Products display

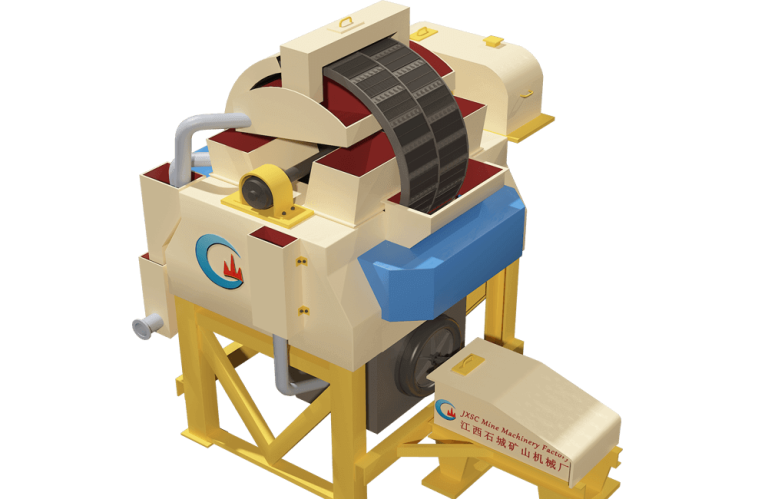

Introduction Of Plate magnetic separator

Plate magnetic separators are designed to attract and remove iron-containing contaminants from granular or free-flowing products. Its corrosion resistance and durability make it a popular wet magnetic separation equipment in the mineral processing industry. It has high magnetic field intensity, long magnetic distance, wide magnetic field, and many magnetic poles, effectively guaranteeing the selection effect. JXSC plate magnetic separators feature an adjustable mounting bracket that allows the flexibility to customize its position and angle according to specific material handling requirements.

A flat-plate magnetic separator uses the synergistic effect of magnetic and mechanical forces to separate magnetic impurities from non-magnetic minerals. This allows for improving the whiteness and quality of non-metallic ores, increasing the grade of weakly magnetic metal ores, and recovering magnetic metals from industrial waste.

It is specifically designed for the efficient extraction or removal of ferromagnetic impurities from powdered and granular materials. Examples include iron removal and purification of non-metallic ores such as quartz sand, feldspar, and kaolin; and wet separation of weakly magnetic metal ores such as hematite, limonite, siderite, manganese ore, ilmenite, and wolframite.

Principle and structure of plate magnetic separator

working principle

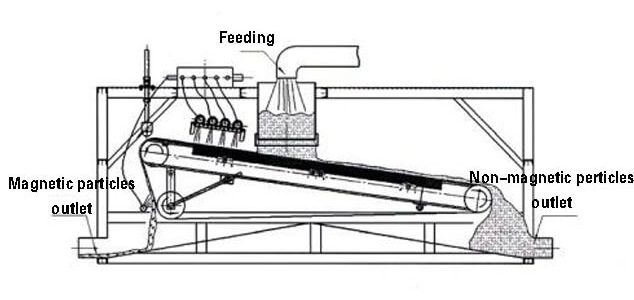

The ore slurry enters the distributor of the magnetic separator through the feed pipe. It is evenly dispersed and scattered on the unloading belt on the upper part of the magnetic plate. Using a belt sorting mechanism, the materials can be magnetically stirred multiple times on the sorting surface from feeding to discharging. At the same time, the non-magnetic tailings are removed under the flushing action of water flow. When the belt moves to the demagnetization zone, the demagnetization device removes the magnetic minerals to complete the mineral processing process.

Structural characteristics

- Magnetic system: Utilizes high-performance rare earth NdFeB magnets or ferrite materials, with a fully sealed structure to prevent oxidation.

- Splitting device: Prevents material accumulation and improves sorting accuracy.

- Demagnetization design: Automatically separates magnetic minerals from tailings.

- Adjustable operating parameters: Plate slope and belt speed can be adjusted via a frequency converter system.

why choose JXSC Plate magnetic separators

Features & advantages Of Plate magnetic separator

1. It adopts high-performance titanium iron boron permanent magnet material and a unique magnetic circuit design, and the magnetic field can reach 15,000G.

2. The installation of the plate magnetic separator is highly flexible; the working area angle and the belt line speed are adjustable, making it suitable for various environments.

3. Belt structure design, large separating area, good effect, clean and thorough discharge.

4. JXSC magnetic separators have low energy consumption, a controllable water supply system, environmental protection, and durability.

models & specifications

| Model | Width(mm) | Length(mm) | Capacity(t/h) | Power (kw) | Dimensions (mm) | weight (T) |

| 600X2000 | 600 | 2000 | 8–10 | 1.5 | 4000x1000x1800 | 2.4 |

| 800X2000 | 800 | 2000 | 10–13 | 1.5 | 4000x1200x1800 | 2.6 |

| 1000X2000 | 1000 | 2000 | 13–18 | 1.5 | 4000x1200x1800 | 2.8 |

| 1200X2500 | 1200 | 2500 | 18–25 | 1.5 | 4500x1600x1800 | 3 |

| 1500X2500 | 1500 | 2500 | 25–30 | 2.2 | 4800x1900x1800 | 3.5 |

| 2000X2000 | 2000 | 2000 | 30–35 | 3 | 4000x2400x1800 | 3.8 |

| 2000X2500 | 2000 | 2500 | 30–35 | 2.2 | 4800x2400x1800 | 4 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.