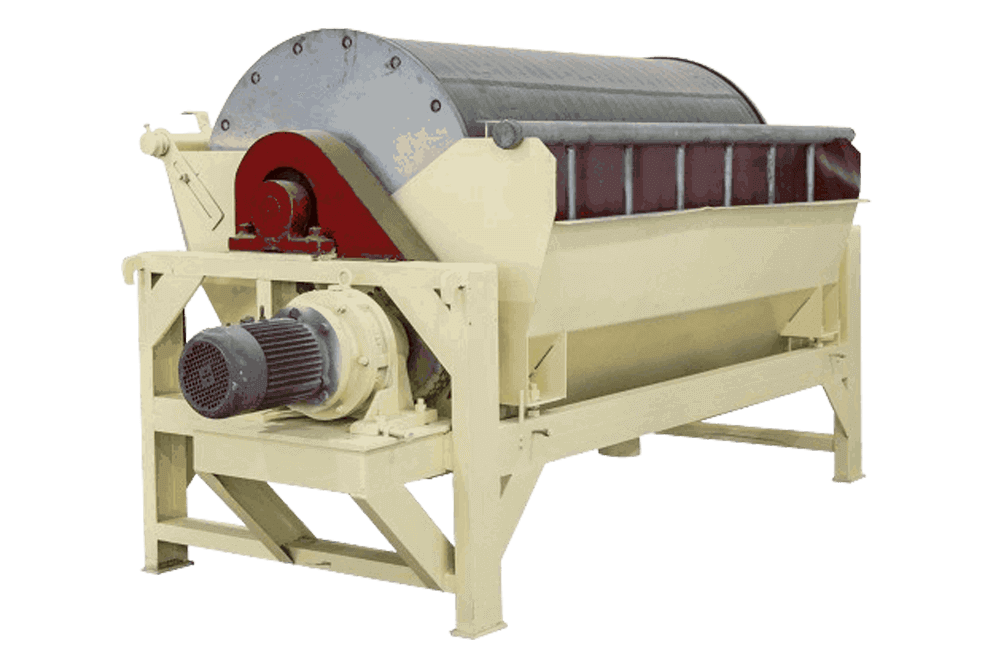

wet drum magnetic separator

Capacity: 0.5-180 t/h

Feed size: ≤3mm

Application: Wet drum magnetic separator is commonly used for wet magnetic separation of pyrite, magnetite, ilmenite, manganese, iron ore, limonite and other materials with particle size below 3mm.

- 95%+ recovery rate.

- Corrosion-resistant drum surface.

- Continuous operation with automatic discharge.

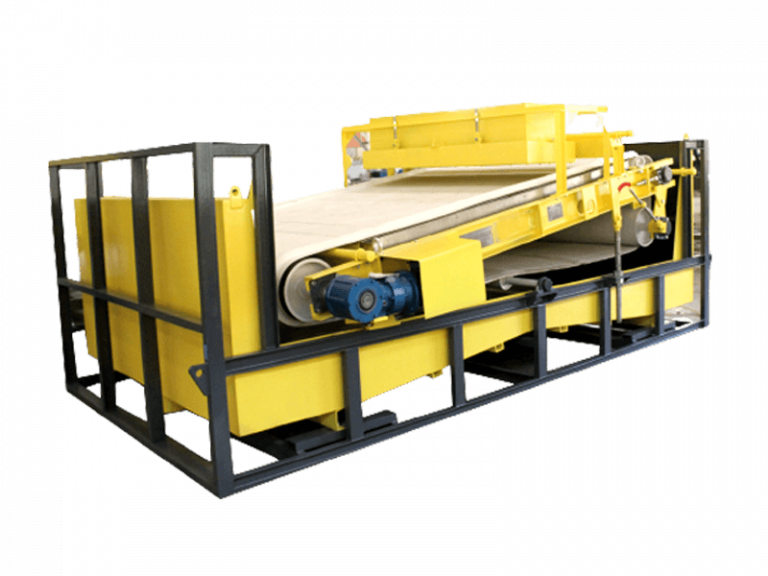

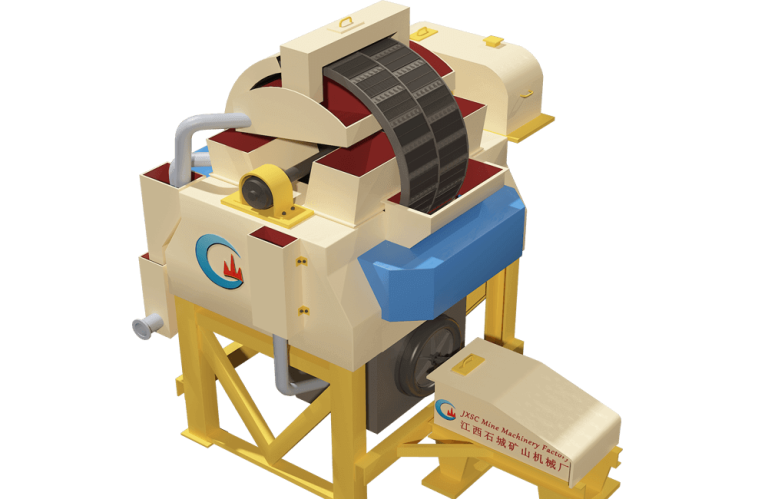

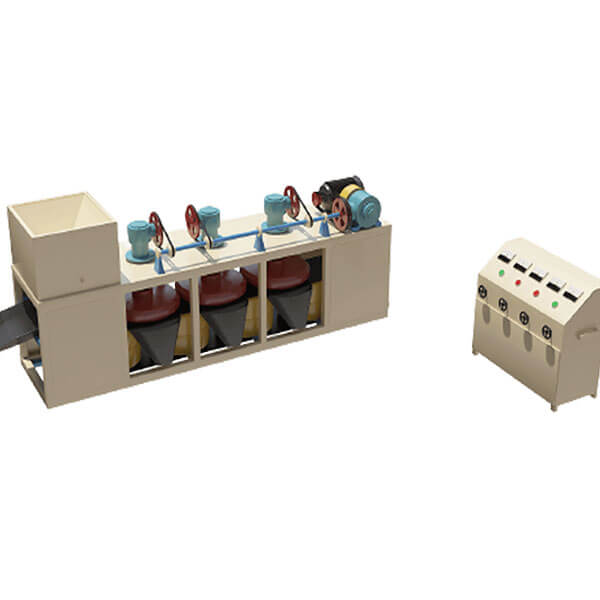

Products display

introduction Of wet drum magnetic separator

Wet drum magnetic separator is a key device for efficiently separating magnetic minerals from ore pulp using permanent magnets or electromagnetic fields. It is an important magnetic separation equipment mainly used for wet separation and purification of various magnetic materials. Such as magnetic separation of ferrous metals and rare metals such as manganese ore, magnetite, hematite, limonite, chromite, ilmenite, tantalite, niobium, rare earth ore, etc. It can also be used for the purification of non-metallic minerals, such as the removal of iron and titanium impurities in quartz, feldspar, and kaolin.

It is mainly capable of effectively separating and recycling magnetic materials from slurry or wet materials. Wet drum magnetic separators are widely used in separating strong magnetic minerals, and can usually be easily integrated into existing mineral processing plants. With its advantages of high magnetic field strength, intelligence, and super wear resistance, it has become an “all-round equipment” for magnetic mineral separation.

The magnetic separator is especially irreplaceable in large-scale iron ore processing plants and precision non-metallic purification, and has realized the modern mineral separation concept of “energy saving, green, and efficient“.

principle & structure Of wet drum magnetic separator

working principle

When the slurry passes through the drum, the magnetic minerals are attracted by the magnetic field and adhere to the surface of the drum. Magnetic minerals adhere to the surface of the drum to form magnetic clusters, and as the drum rotates, they are brought to one side or the bottom of the drum and then scraped off the drum by a scraper or other equipment. Magnetic minerals are effectively separated. The attraction does not attract non-magnetic minerals and continues to pass through the roller and are eventually discharged from the magnetic field.

Structural characteristics

- Permanent magnet system: Utilizes neodymium iron boron or rare earth composite magnets, providing a uniform magnetic field with a high gradient.

- Drum assembly: The drum shell is constructed of 304 stainless steel, with some models coated with wear-resistant ceramic or rubber to resist ore impact and wear.

- Multi-functional trough system: Available in co-current, counter-current, and semi-counter-current configurations, adapting to roughing (counter-current), cleaning (co-current), and scavenging (semi-counter-current) process requirements.

- Intelligent control: Equipped with a PLC control system, the magnetic field strength can be adjusted in real time.

why choose JXSC wet drum magnetic separator

features & advantages Of wet drum magnetic separator

1. It has high recovery rate, large processing capacity and high degree of automation, and can be applied to industries such as ferrous metal beneficiation, non-ferrous metal recovery and non-metallic mineral purification.

2. JXSC drum magnetic separator has a rugged construction that can withstand abrasive materials and corrosive environments.

3. Its rotating drum design allows continuous material flow through the magnetic field, effectively capturing iron particles and delivering a high-purity end product.

4. We support custom equipment or adjustable magnetic field strength to meet specific processing requirements, ensuring optimal performance and efficiency.

5. High-precision sorting, magnetic mineral recovery rate of 90%-98%, concentrate grade increased by 30%-50%.

6. It can process coarse particles and recycle fine particles, and has a wide range of particle sizes.

7. The magnetic separators are available in various sizes and configurations, allowing for high-capacity processing of materials.

models & specifications

Model | Shell diameter | Shell length | Shell rotation speed | Feeding size | Processing capacity | Power |

CTB4060 | 400 | 600 | 48 | 2-0 | 0.5-1 | 1.1 |

CTB6012 | 600 | 1200 | <35 | 2-0 | 10–20 | 1.5 |

CTB6018 | 600 | 1800 | <35 | 2-0 | 15–30 | 2.2 |

CTB7518 | 750 | 1800 | <35 | 2-0 | 20–45 | 2.2 |

CTB9018 | 900 | 1800 | <35 | 3-0 | 40–60 | 3 |

CTB9021 | 900 | 2100 | <35 | 3-0 | 45–60 | 3 |

CTB9024 | 900 | 2400 | <28 | 3-0 | 45–70 | 4 |

CTB1018 | 1050 | 1800 | <20 | 3-0 | 50–75 | 5.5 |

CTB1021 | 1050 | 2100 | <20 | 3-0 | 50–100 | 5.5 |

CTB1024 | 1050 | 2400 | <20 | 3-0 | 60–120 | 5.5 |

CTB1218 | 1200 | 1800 | <18 | 3-0 | 80–140 | 5.5 |

CTB1224 | 1200 | 2400 | <18 | 3-0 | 85–180 | 7.5 |

CTB1230 | 1200 | 3000 | <18 | 3-0 | 100–180 | 7.5 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.