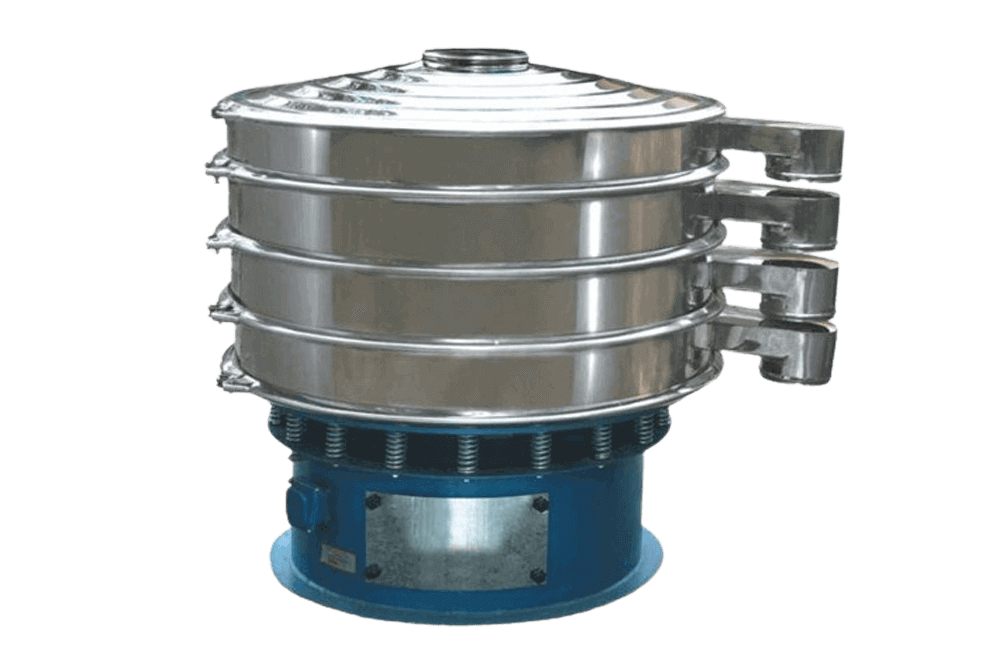

Rotary Vibrating Sieve

Screening Size: 0.2281-2.7922 m²

Layer: 1-5

Application: Rotary vibrating sieve is widely used in food, environmental protection, abrasives, metallurgy, mining, and other industries; screening, filtration, and classification of alumina, silica sand, metal powder, and other materials.

Products display

introduction of Rotary Vibrating Sieve

Rotary vibrating sieve, also known as rotary vibration filter sieve, vibratory separator, is a high-precision fine powder screening equipment. It is usually suitable for the screening and filtering stage of particles, powders, and viscous liquids. The main functions are to remove impurities, filter, classify materials, separate solids and liquids, and screen. It has the characteristics of small size, fully enclosed structure, high performance, low noise, and no dust or liquid spillage. Through various sieves with different mesh sizes (or apertures), different granular, powdery, liquid, and other materials can be continuously screened or filtered to meet the different needs of various materials.

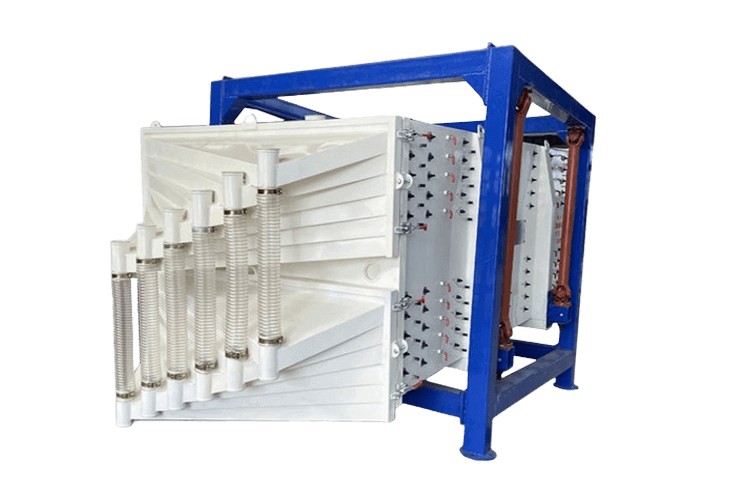

This rotary vibrating screen has a unique vortex motion trajectory, which can effectively solve the problems of fine powder blocking the screen and sticky and wet materials being difficult to screen. It is widely used in ultra-fine powder classification, high-precision impurity removal, slurry filtration, and other scenarios. Compared with other screening equipment, the linear vibrating screen mainly adopts a modular box structure, a dead angle-free screen tensioning system, and variable frequency vibration control technology.

Working principle of rotary vibrating sieve

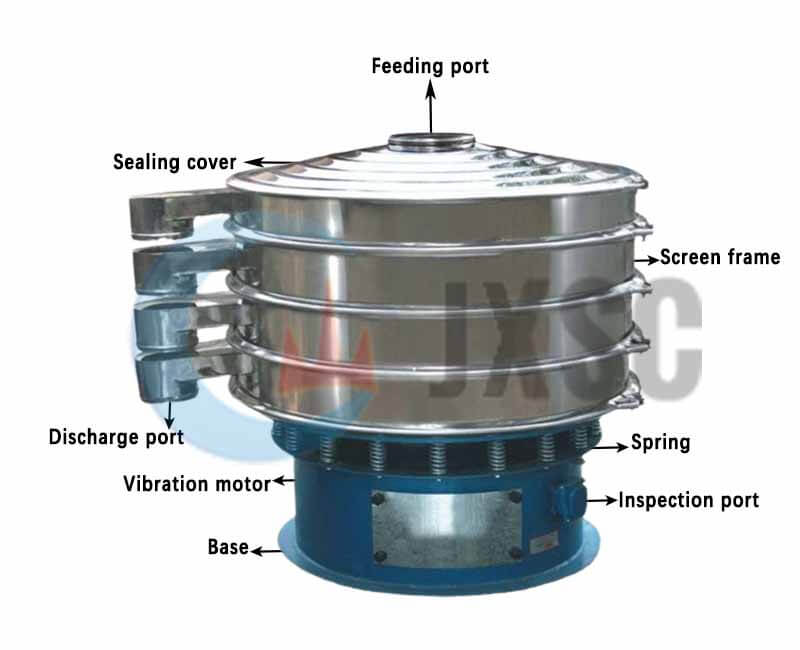

This rotary vibrating screen is mainly composed of a screen box (steel plate/stainless steel), a multi-layer screen (stainless steel/polyurethane woven), a vibration motor, a shock-absorbing spring and a base. It has a fully enclosed design that effectively prevents dust from spilling out, and is suitable for screening and filtering materials such as particles, powders, and mucus.

This rotary vibrating screen uses a vertical motor as the vibration source. The motor is equipped with eccentric hammers on the top and bottom to make the rotating motor move in horizontal, vertical and inclined directions. The rotation of the motor causes the material on the screen surface to spread. By adjusting the relative phase of the eccentric blocks at the upper and lower ends of the vibration motor, the movement trajectory of the material on the screen surface can be changed, thereby achieving different screening operation purposes.

Why Choose JXSC Rotary Vibrating Sieve

features & advantages

1. High screening accuracy, wide range of material particle size; long motion trajectory, high screening area utilization.

2. Fully enclosed structure, low noise, no powder flying, no material pollution.

3. Made of stainless steel, smooth surface, easy to clean.

4. Small size, light weight, easy to disassemble or move.

5. The sieve holes are not easy to clog, the sieve can be quickly replaced in 3-5 minutes, easy to operate and maintain.

6. The direction of the discharge port can be adjusted according to needs. Coarse and fine materials are automatically discharged, with automatic or manual operation.

7. Three, four, or more layers can be customized, and one material can be sorted into multiple different specifications at the same time.

models & specifications

Model | Screening Size | Layer | Screen Diameter(mm) | Screen Mesh | Motor Power | |

600 | 0.2281 | 1-5 | Φ540 | 2-500 | 0.55 | 0.75 |

800 | 0.4183 | 1-5 | Φ730 | 2-500 | 0.75 | 1.1 |

1000 | 0.6359 | 1-5 | Φ900 | 2-500 | 1.1 | 1.5 |

1200 | 0.9499 | 1-5 | Φ1100 | 2-500 | 1.5 | 1.5 |

1500 | 1.5386 | 1-5 | Φ1400 | 2-500 | 2.2 | 2.2 |

1800 | 2.2687 | 1-3 | Φ1700 | 2-500 | 3.0 | 2.2 |

2000 | 2.7922 | 1-3 | Φ1886 | 2-500 | 3.7 | 3.0 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.