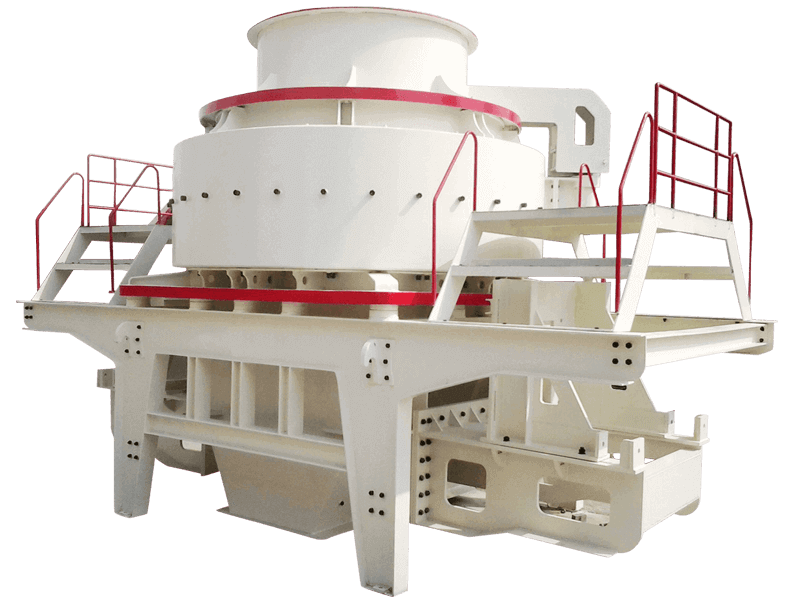

VSI Sand Maker

Capacity: 120-640t/h

Feeding size: 30-50mm

Application: The VSI sand makers are widely used for granite, quartz, basalt, river pebble, limestone, dolomite, calcite, quartz stone, construction waste etc., ore crushing, sand making plant

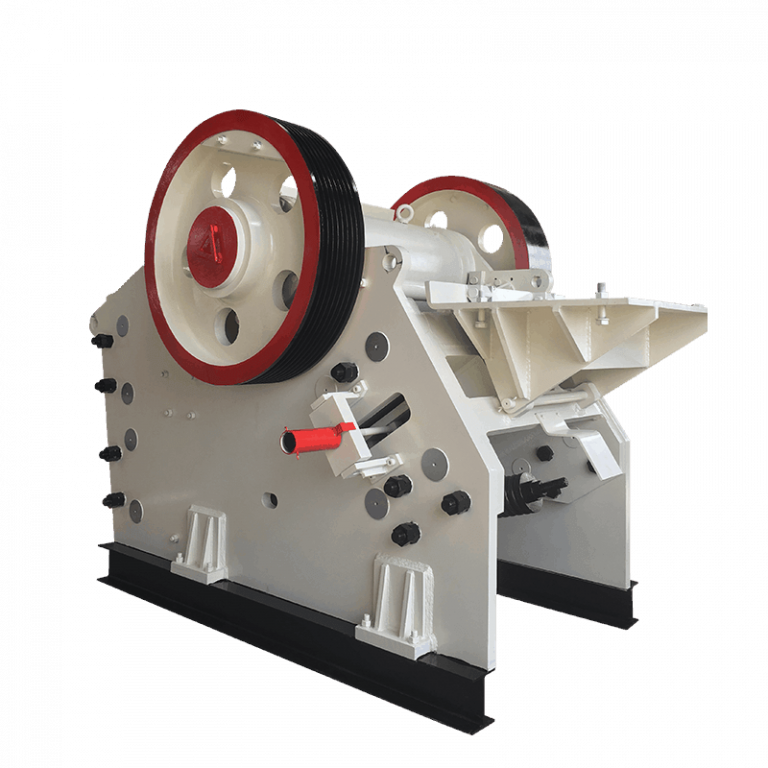

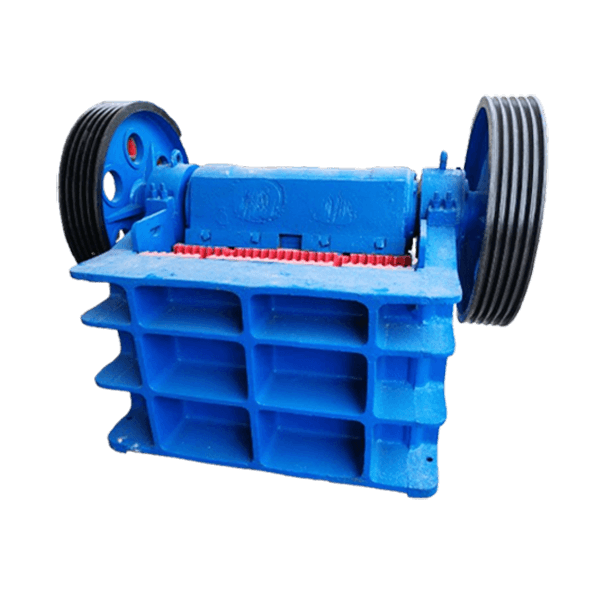

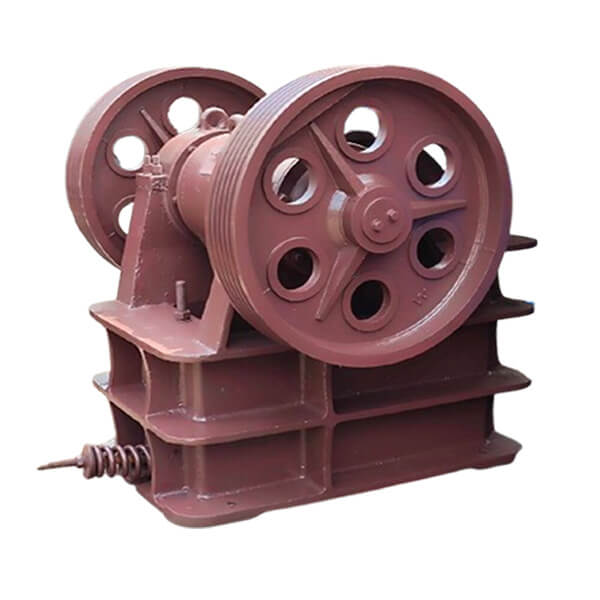

Products display

Introduction of VSI sand maker

VSI sand maker is also called VSI sand making machine, VSI crusher, vertical shaft impact sand making machine and shaping machine. The vsi sand making machine is widely used in sand and gravel plants, concrete sand making, machine-made sand, and other stone and ore crushing plants. The finished product is far more in line with construction requirements than natural sand and sand produced by ordinary hammer sand making machines, and can improve construction quality. It can provide high-quality sand and gravel aggregates for highways, high-speed railways, high-rise buildings, municipal construction, hydropower dam construction, and concrete mixing stations, which is the guarantee for artificial sand and stone production.

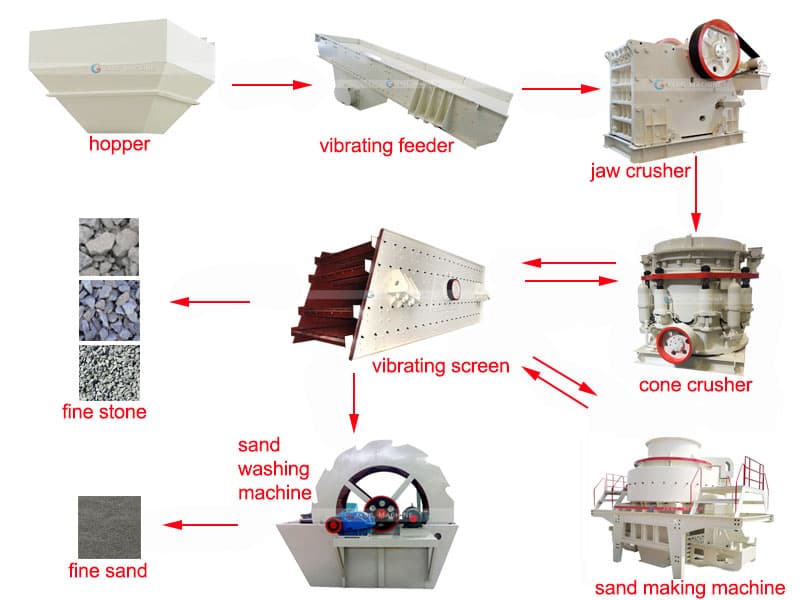

Usually, the vsi sand maker can be combined with sand washing machine, crusher, vibrating screen, vibrating feeder, etc other equipment to form a sand making plant, a more economical and efficient production line. JXSC can customize fixed or mobile sand-making machines and various crushing equipment.

With its the advantages of high-quality sand, good particle shape, multi-functional integration, and low energy consumption. It is widely used in the fields of sand and gravel aggregates and construction engineering for artificial sand making and stone shaping.

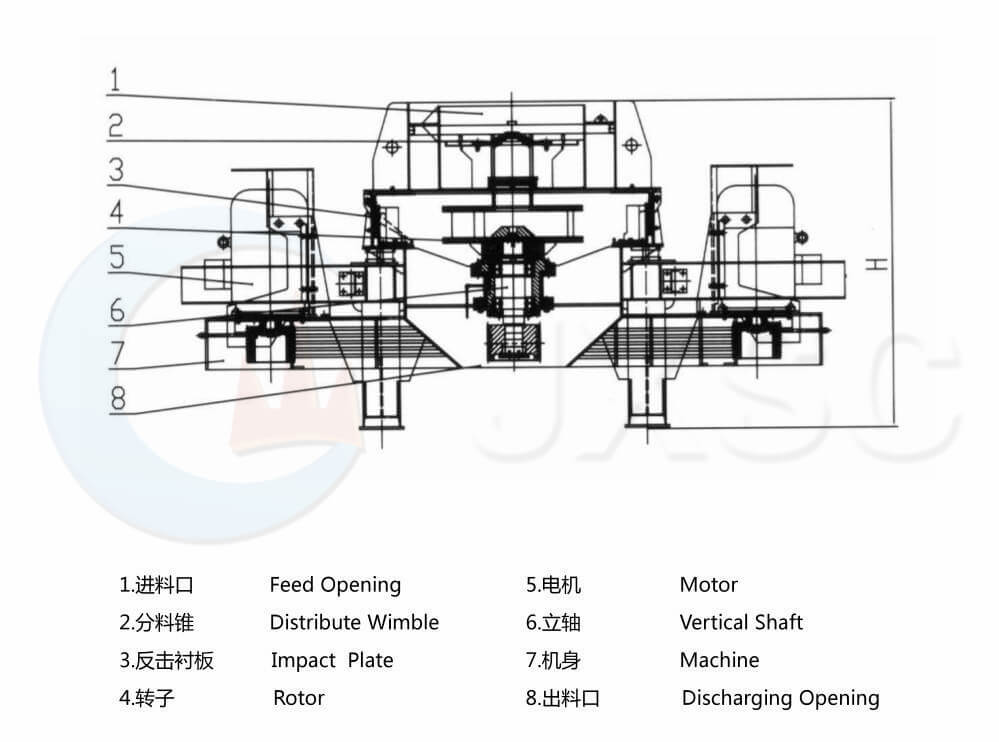

working principle & structure of VSI sand maker

Working principle

The VSI sand making machine uses high-speed rotating materials to break each other by themselves and friction between materials. The material falls into the feed port, enters the high-speed rotating rotor through the center feed hole, and is fully accelerated and thrown out through the launch port. It first collides with the rebounding free-falling part of the material, and then hits the vortex material lining (or counter-block) in the surrounding vortex chamber.

Then, it is bounced to the top of the crushing chamber, and then turns to move downward, and impacts with the material coming out of the impeller runner to form a continuous material curtain, and finally discharges through the lower discharge port.

Structural features

- Advanced feeding device: adopts unique material distribution plate design to achieve continuous crushing and shaping of materials.

- High-efficiency rotor: rotates at high speed, accelerates and throws the material, generates strong impact force for crushing.

- Double-chamber crushing chamber: supports automatic switching of two crushing modes: “stone hitting stone” and “stone hitting iron”.

- Discharge port setting: equipped with adjustable discharge port, which can adjust the discharge of materials according to particle requirements.

- Casing: Made of high-strength steel, providing good stability and pressure resistance.

why choose JXSC vSI Sand maker

features & Advantages of VSI Sand Maker

- High crushing efficiency: the output of VSI sand maker is as high as tons, and the sand processing capacity meets the task requirements.

- High-quality finished products: stone-on-stone crushing is formed in the crushing chamber, and the effect of stone particle shape is higher than that of ordinary sand making machines, and the product discharge is easier. The finished product of the sand making machine is completely superior to natural sand. With the function of shaping, the finished product after crushing is cubic, with uniform grain shape, adjustable fineness modulus. The particles are round, the grading is excellent, the powder content is controllable, and it meets the national Class I sand standards.

- Low loss: good material technology support, reasonable crushing cavity; reduce friction between materials and wear-resistant parts, prolong service life.

- Automatic adjustment: The impeller speed and feed amount can be adjusted online through the hydraulic device to flexibly meet different needs.

- Easy maintenance: The hydraulic cover opening device is easy to repair and maintain, saving time and effort. Over-vibration display and alarm device, automatic detection, reliable.

- Long life design: core components (impeller, wear-resistant block) are made of high-strength alloy, and the maintenance cycle is extended by 50%.

- Environmental protection: less dust, low noise, can be equipped with dust removal devices of various specifications, and increase environmental protection.

- JXSC VSI sand making machine can also be equipped with crushing, feeding, conveying and other equipment to form an integrated mobile sand making station.

models & specifications

Vertical Shaft Sand Maker | Soft material+10% | |||||

Model | Max Feeding size | Throughput(M3) | Capacity(M3) | Speed of mainshaft R/MIN | KW | Dimension (MM) |

DN-5000 | 35mm | 40-60 | 20-35 | 1700-1890 | 90 | 3800*2180*2425 |

DN-6000 | 35mm | 60-80 | 30-40 | 1560-1720 | 160 | 4240*2200*2778 |

DN-7000 | 40mm | 100-120 | 40-50 | 1550-1650 | 132*2 | 4700*2200*2850 |

DN-8000 | 40mm | 160-200 | 64-80 | 1400-1720 | 160*2 | 5200*2250*3250 |

DN-8500 | 45mm | 180-200 | 72-80 | 1400-1720 | 200*2 | 5200*2350*3250 |

DN-9000 | 45mm | 220-250 | 80-96 | 1510-1650 | 250*2 | 5200*2450*3250 |

DN-9500 | 45mm | 250-270 | 96-108 | 1510-1650 | 280*2 | 5200*2250*3450 |

DN-10000 | 50mm | 270-350 | 120-180 | 1480-1600 | 315*2 | 5200*2250*3450 |

Note: the above capacity is based on the loose specific gravity of 1.6t/m3 rock stone | ||||||

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.