Wheel Sand Washing Machine

Capacity: 15-200 t/h

Application: Wheel sand washing machine is mainly used in mining, mineral processing, construction, road construction, bridge engineering, aggregate processing plant, sand and gravel plant, concrete production industry; such as limestone, calcite, granite, pebbles, iron ore, phosphate rock, quartz sand, construction sand and other materials, ore or sand washing equipment.

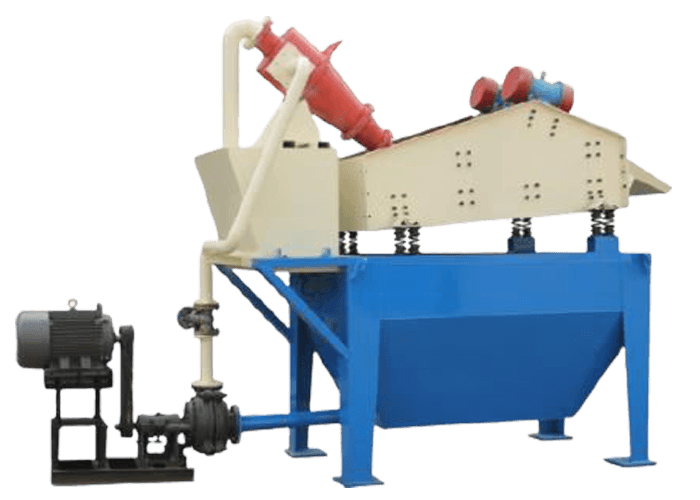

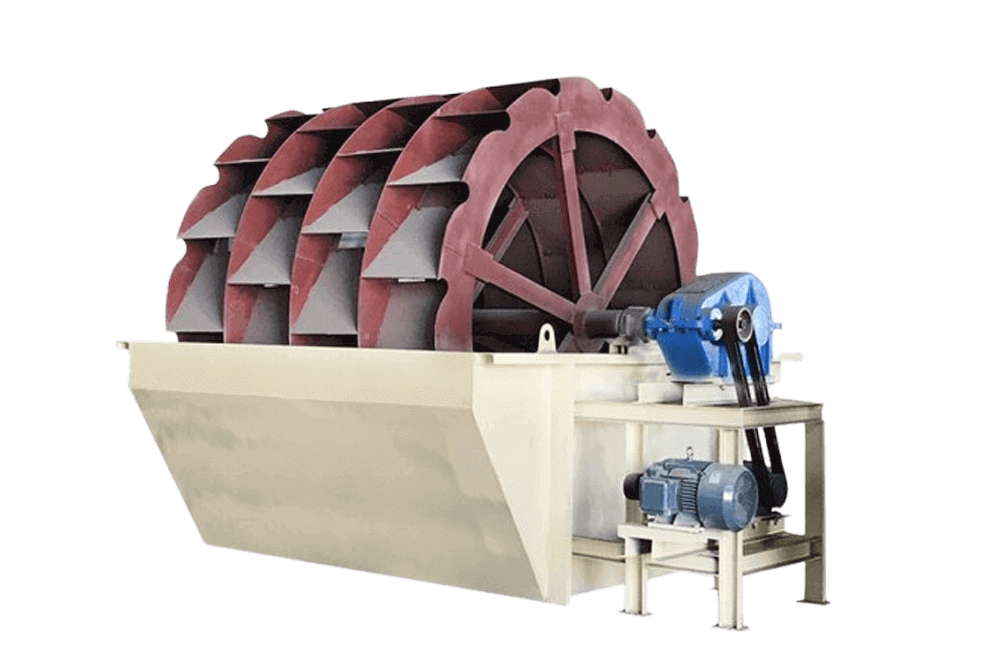

Products display

Introduction of Wheel Sand Washing machine

Wheel sand washing machine, wheel bucket sand washer are key equipment used for washing, grading, impurity removal, and dehydration in sand and gravel plants. It is often used to clean natural sand or artificial sand, remove soil, dust, and other impurities, so as to improve the cleanliness and quality of sand. While cleaning, the wheel sand washer can classify the sand and gravel by size, separate products of different particle sizes, and facilitate subsequent screening and use. JXSC wheel sand washing machine is suitable for cleaning sand and gravel of different types and particle sizes. It can operate continuously, large processing capacity, and strong cleaning efficiency. It is suitable forwashing, desludging, or impurity separation of river sand, lake sand, sea sand, quartz sand, silica sand, sand and gravel aggregate, slag, tailings sand, minerals after mine crushing, and other materials.

It is a popular, high-efficiency, and energy-saving sand washing equipment in the construction, water conservancy engineering, and mining industries. JXSC supports the configuration of two, three-wheel or four-wheel sand washing machines, mainly depending on your production needs, material characteristics and expected sand washing effects.

The wheel sand washer can also be equipped with a fine sand recovery machine to form a modular sand washing-dehydration-recovery integrated machine.

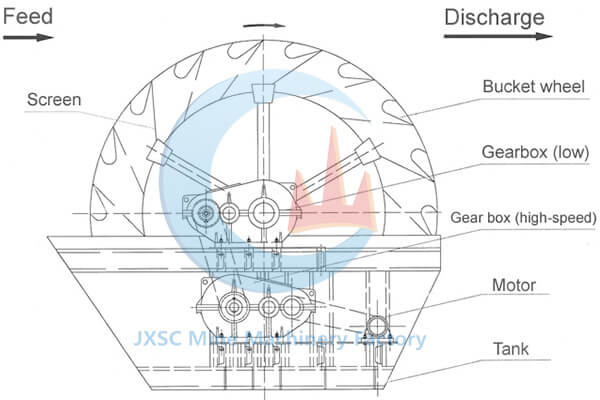

Principle and structure of wheel sand washing machine

Working principle

The motor-driven impeller rotates slowly after the V-belt, reducer, and gear reduce speed. The sand enters the washing tank from the feed tank and rolls under the drive of the impeller, grinding away the impurities covering the surface of the sand and gravel, and at the same time destroying the water vapor layer covered by the sand particles to facilitate dehydration.

The eject water forms a strong water flow, timely removing impurities with small specific gravity, and is discharged from the overflow port flushing tank to complete the cleaning effect. The clean sand and stone are taken away by the blade, and then the sand is poured from the rotating impeller into the discharge tank to complete the cleaning of the sand and stone.

Structural characteristics

• Low noise and vibration

• Strong adaptability

• Stability and reliability

• Wear-resistant design

• Low energy consumption

• Simple operation & maintenance

• Water circulation system

why choose JXSC Wheel Sand Washing machine

features & Advantages

1. Less sand loss during sand washing, high fine sand recovery rate.

2. It is designed to be wheel-driven, and has good cleaning effect through water flushing and mechanical stirring.

3. The wheel bucket sand washer can grade materials while washing, and the quality of sand and gravel after washing is good.

4. It can wash sand and gravel of different particle sizes, and can adapt to various production conditions, with strong adaptability.

5. Reliable transmission device, stable operation, durable equipment, and relatively low maintenance cost.

6. It has high production efficiency and processing capacity, and can meet the needs of large-scale production.

7. The design of this sand washing machine usually focuses on water recycling and reduces water consumption.

8. JXSC wheel sand washing machine can be single-wheel, double-wheel, three-wheel or four-wheel configurations.

models & specifications

| Model | Diameter of The Wheel Bucket(mm) | Speed of Rotation(r/min) | Maximum Feeding Size(mm) | Process Capacity(t/h) | Motor Power(kw) | Overall Dimensions(mm) | Weight(kg) |

| XS22-2 | 2200 | 2.5 | ≤10 | 15-30 | 4 | 3180*1955*2350 | 2260 |

| XS26-2 | 2600 | 2.5 | ≤10 | 20-50 | 5.5 | 3515*2070*2672 | 2500 |

| XS28-3 | 2800 | 1.2 | ≤10 | 50-80 | 11 | 3964*3014*2895 | 3200 |

| XS28-4 | 2800 | 1.17 | ≤10 | 60-100 | 15 | 3964*2137*2895 | 3580 |

| XS30-4 | 3000 | 1.2 | ≤10 | 70-110 | 15 | 4169*3456*3055 | 3850 |

| XS32-3 | 3200 | 1 | ≤10 | 80-120 | 15 | 4340*2760*3349 | 3950 |

| XS32-4 | 3200 | 1.17 | ≤10 | 95-130 | 18.5 | 4346*2198*3345 | 4185 |

| XS36-5 | 3600 | 1 | ≤10 | 110-200 | 22 | 4580*3218*3600 | 4600 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.