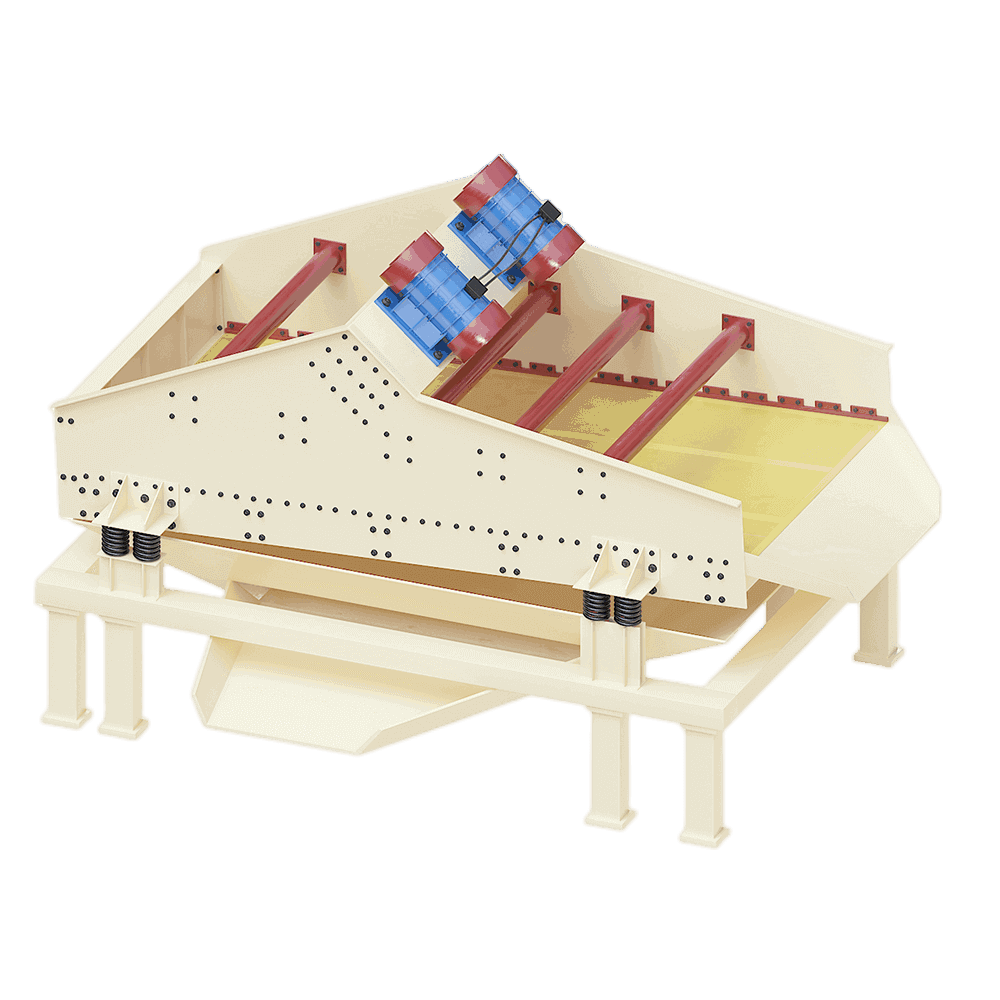

dewatering screen

Capacity: 5-250 TPH

Screen material: PU, PE, and other materials;

Screen size: 1.6-10.8m³

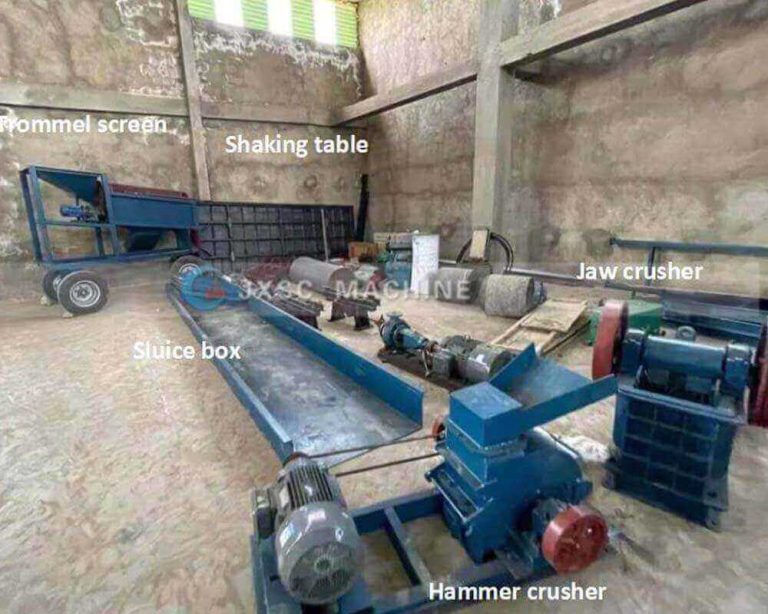

Application: Dewatering screens are mainly used in metal mine tailings, washed sand/machine-made sand, coal slime/coal gangue, and dry tailings discharge scenarios; for example, the dewatering process of minerals and sand and gravel such as gold, copper, lead-zinc, manganese, tin, quartz sand, graphite, zircon sand, silica sand, limestone, and granite sand.

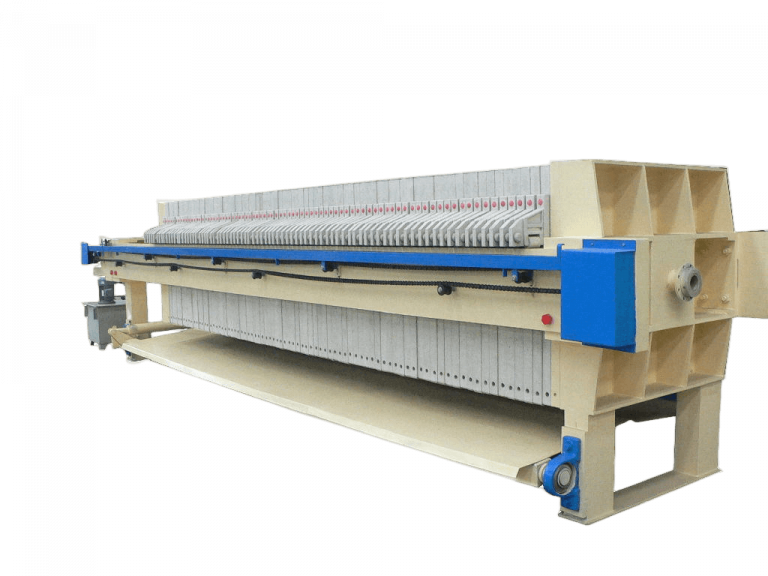

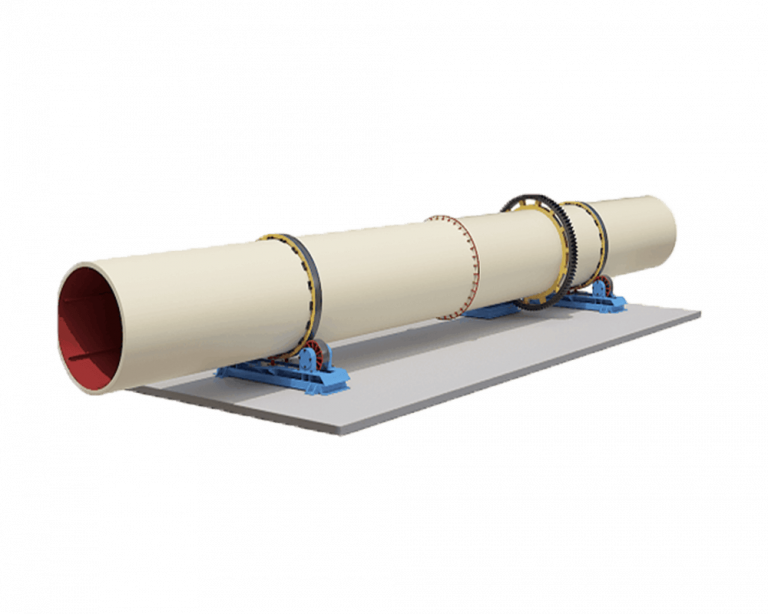

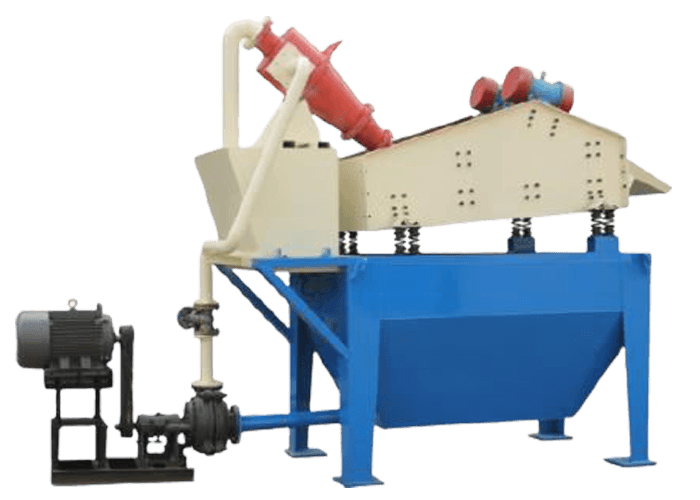

Products display

introduction of dewatering screen

The dewatering screen is also called “dewatering vibrating screen”, a common mining dewatering equipment. Also called sand and gravel dewatering screen, mining dewatering screen, coal slime dewatering screen, tailings dewatering screen, etc. The main function of the machine is dehydration, desliming, and demediation to solve the problem of water content of the material. Through high-frequency vibration and screen surface inclination design, moisture can be quickly removed, and it is used to process wet mineral processing, sand washing, tailings and other water-containing materials.

This dewatering screen has the advantages of low energy consumption, high adaptability, and non-clogging. It is mainly used for the dehydration of tailings in the mineral processing industry, coal slime dehydration of coal preparation plants, and dehydration of washed quartz sand and ceramic slurry; in mining and industrial industries, it is used for dry-wet classification, dehydration, disintermediation and desliming of medium and fine materials.

The dewatering screen can also be equipped with a sand washing machine, a hydrocyclone, and other machines to form an integrated fine sand recovery machine, which can form a one-stop collective washing, grading, and dehydration.

Principle and structure of dewatering screen

Working principle

The machines adopt dual-motor self-synchronization technology, a general-purpose eccentric block, and an adjustable amplitude vibrator. The material with high water content is introduced into the basket or cylinder of the dewatering screen through the feed port. The material is moved at high speed by the centrifugal force of the on screen. Moisture is separated from solid materials to form two parts: water and solid materials. The separated water is discharged through the discharge port of the machine, while the solid materials continue to stay inside the machine. The separated solid material is collected through the equipment’s receiving port to complete dehydration.

Structural characteristics

- Screen box structure: Welded from high-strength steel; adjustable inclination angle.

- Screen design: Polyurethane, stainless steel, or metal composite screen plates are available, offering wear resistance and anti-clogging properties. Various apertures are available to meet grading requirements.

- Vibration motor: Dual self-synchronizing motors provide high excitation force.

- Shock absorption system: Supported by rubber springs or composite shock absorbers.

why choose JXSC dewatering screen

features & Advantages of dewatering screen

1. It can be used in metal mines, such as dry discharge of iron/copper tailings and dehydration of concentrates; sand and gravel aggregates: machine-made sand washing line and dehydration of construction sand; coal industry: coal slime dehydration and heavy medium recovery.

2. The sieve holes are not easy to clog, the dehydration effect is good, the screening accuracy is high, and the processing capacity is large.

3. JXSC dewatering equipment can be used in sand washing, ore dressing plants, tailings dry discharge, etc., with a wide range of applications.

4. Polyurethane/rubber screen plate (opening rate 35%-60%) is used, and its service life is extended by 3 times compared with metal screen.

5. The screen inclination is adjustable (0°-15°), and combined with the amplitude adjustment, the dehydration effect can be optimized according to the material characteristics (for example, the amplitude needs to be increased for sticky coal slime).

6. It uses dual vibration motor drive, which saves more than 60% energy compared to the filter press. No complex transmission parts, and only needs to replace the screen regularly, which has low maintenance cost.

7. Flexible options are provided for screen material, number of layers, size, etc. to meet special process requirements.

models & specifications

Model | Screen Size(m³) | Motor Power(kw) | Input Size(mm) | Capacity(t/h) |

DN0820 | 1.6 | 0.75*2 | <10 | 5-10 |

DN1020 | 2 | 1.1*2 | <10 | 10-20 |

DN1225 | 3 | 2.2*2 | <10 | 30-50 |

DM1530 | 4.5 | 3*2 | <10 | 50-70 |

DN1836 | 6.5 | 3.7*2 | <10 | 70-110 |

DN2040 | 8 | 5.5*2 | <10 | 120-160 |

DN2245 | 9.9 | 15*2 | <10 | 160-220 |

DN2445 | 10.8 | 18.5*2 | <10 | 220-250 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.